Stable low-noise permanent magnet motor

A permanent magnet motor, low noise technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems that the permanent magnet motor can not continue to complete the shock and noise reduction function, affect the normal operation of the permanent magnet motor, etc., to improve stability performance, improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be described in further detail below in combination with specific embodiments.

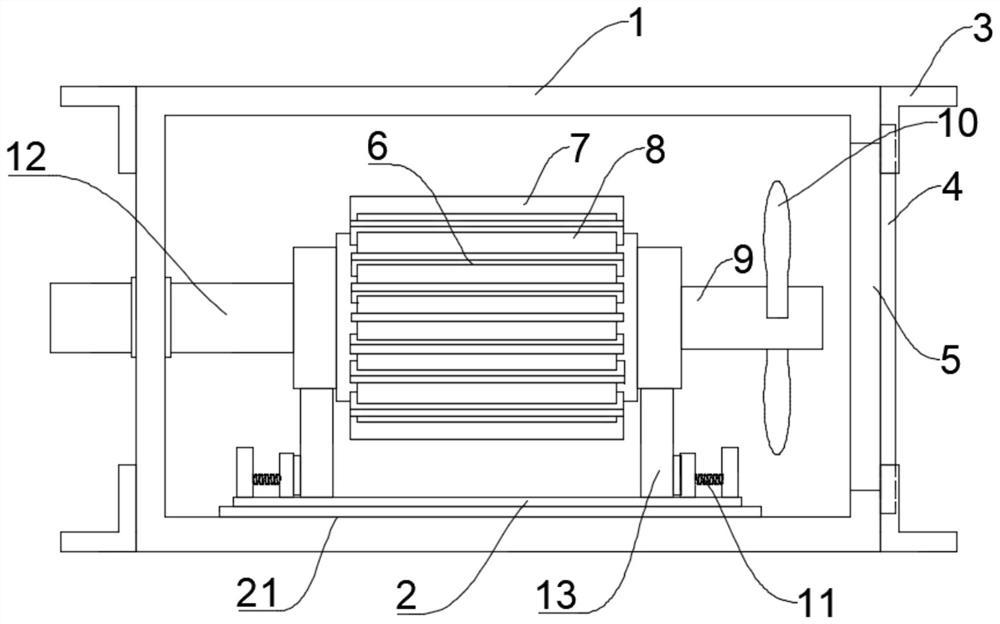

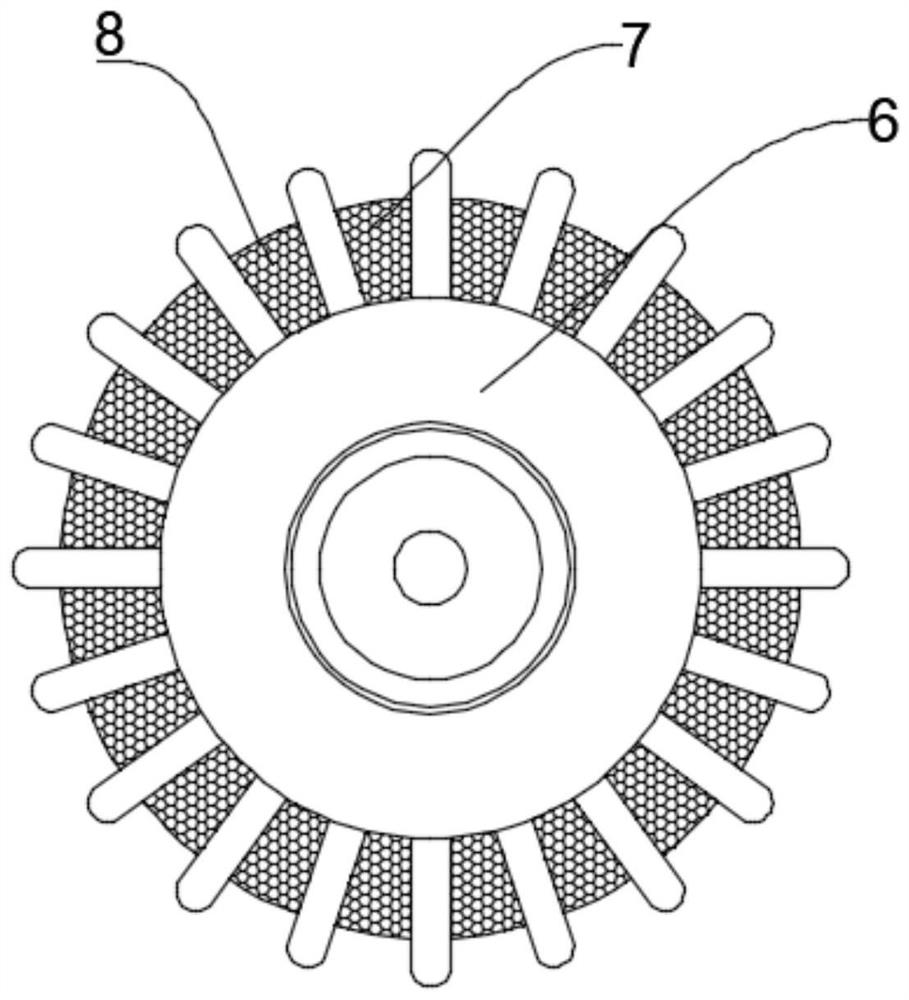

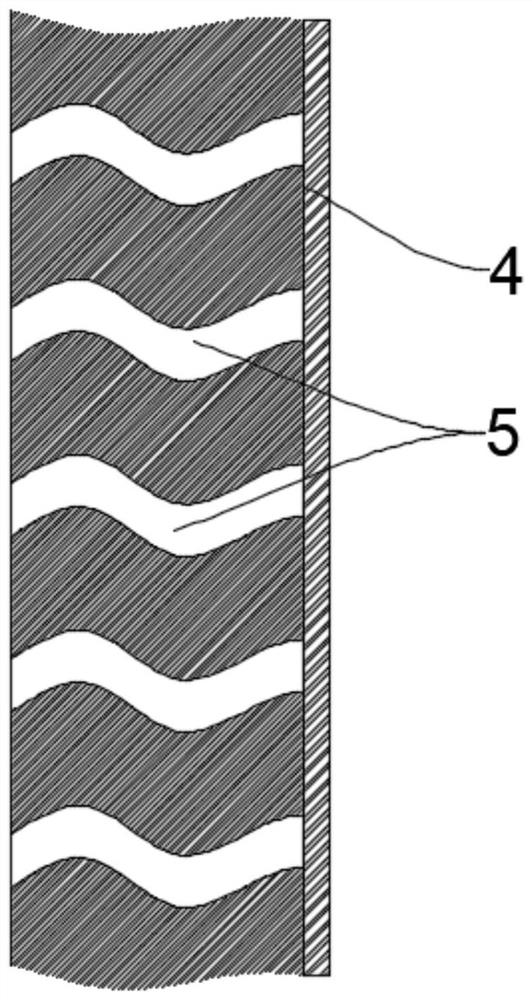

[0023] like figure 1 and figure 2 As shown, in the embodiment of the present invention, a stable low-noise permanent magnet motor includes a motor body 6, an installation box 1 and a fixing assembly 11, the motor body 6 is installed in the installation box 1, and the output shaft of the motor body 6 12 extends out of the installation box 1, and the installation box 1 is provided with a communication hole 5 for gas exchange along the side plate in the length direction of the motor body 6, and the installation box 1 is fixed at the installation position through a number of connecting seats 3 provided on the outside. The side of the motor body 6 is provided with a plurality of cooling fins 8, and sound-absorbing parts are filled between the adjacent cooling fins 8, and the plurality of cooling fins 8 cooperate with the fan assembly 10 inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com