Fixture for precision medical instrument machining

A technology for medical devices and fixtures, applied in the field of fixtures for precision medical device processing, can solve the problems of single clamping method, reduced product accuracy, and prone to offset, so as to improve processing accuracy, increase production speed, and improve positioning and clamping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

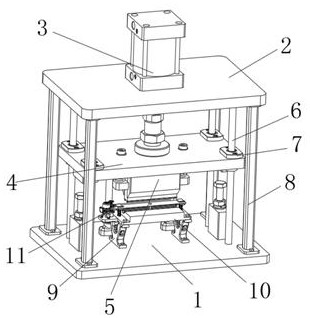

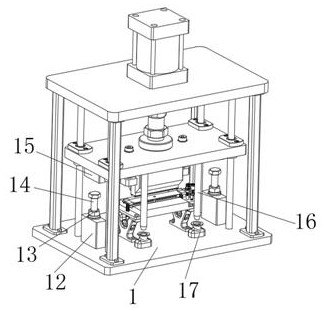

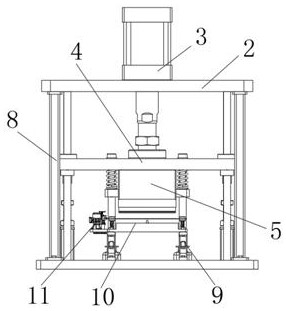

[0025] Example: Reference Figure 1-8 A jig for processing precision medical instruments is shown, including a driving clamping part 11;

[0026] The driving clamping part 11 includes a driving clamping unit and a positioning clamping unit, the driving clamping unit is used to clamp the workpiece, and drives the workpiece to rotate to the bottom of the mold assembly, and the positioning clamping unit is used to position the workpiece on the driving clamping unit Clamping; frame and die assemblies are also disclosed in this embodiment.

[0027] As an implementation mode in this embodiment, the frame includes a base plate 1, columns 8 are fixedly connected around the top of the base plate 1, and the same upper base plate 2 is fixedly connected to the tops of the four columns 8, and the mold assembly is connected with the base plate 1 and The upper base plate 2 is connected, the mold assembly includes a pneumatic telescopic rod assembly 3 fixedly connected to the top of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com