Device capable of adjusting large shaft turning jack

A jack and lathe processing technology, applied in the direction of lifting device, auxiliary device, metal processing equipment, etc., to achieve the effect of avoiding accidents and quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

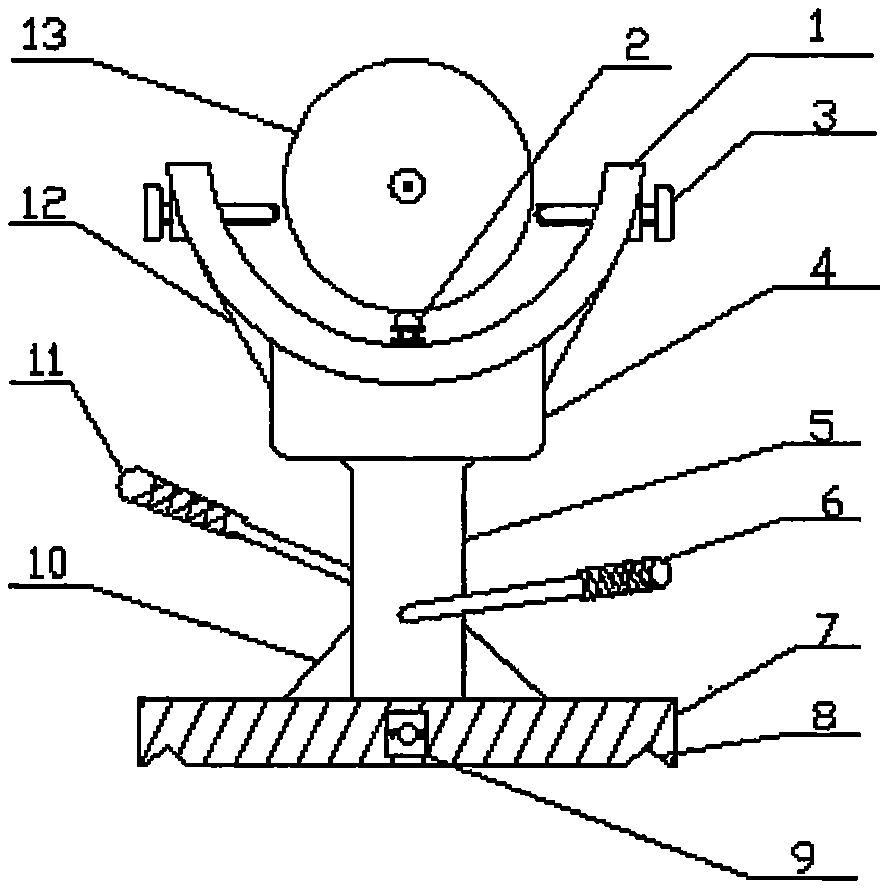

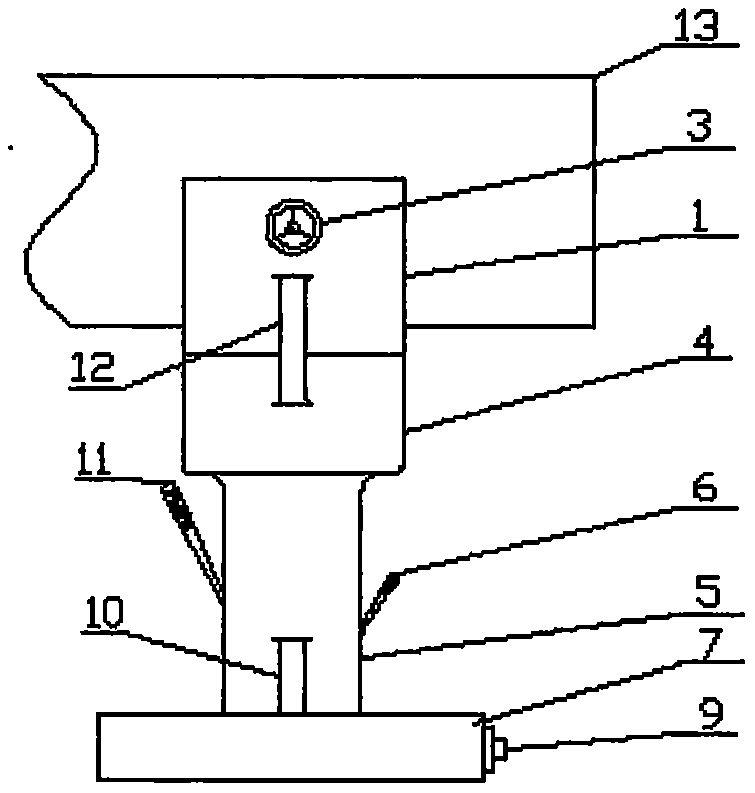

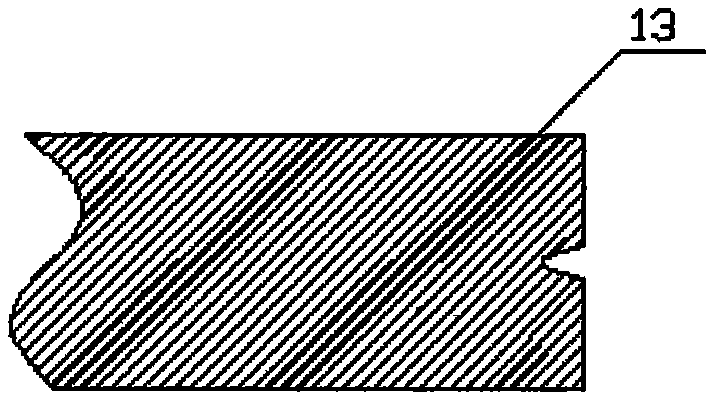

[0017] exist figure 1 , 2 , 3, 4, can adjust the large axle car processing jack device, magnetic base 7 is a rectangular shape, the front is provided with knob type magnetic switch 9, the both sides of magnetic base 7 is provided with V-shaped groove 8, V-shaped groove 8 and lathe The track coincides; the upper end of the magnetic base 7 is a jack 5, the two sides of the jack 5 are provided with reinforcing ribs 10 to be connected with the magnetic base 7, the front of the jack 5 is provided with a quick pressure lever handle 6, and the reverse side is provided with a fine-tuning pressure lever handle 11, and the jack 5 There is a hydraulic mechanism inside, the upper end of the jack 5 is connected with the rectangular support frame 4, the top of the rectangular support frame 4 is provided with an arc groove, the top of the rectangular support frame 4 coincides with the arc bracket 1, and the rectangular support frame 4 and Both sides of the arc bracket 1 are connected with r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com