Forming mold, vulcanizing machine and rubber part forming method

A technology for forming molds and rubber parts, applied in the field of forming molds, vulcanizers and rubber parts, can solve the problems of complex forming, difficult mold release, and inability to mass-produce, achieve stable flatness, solve the problem of mold release difficulty, Looks perfect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

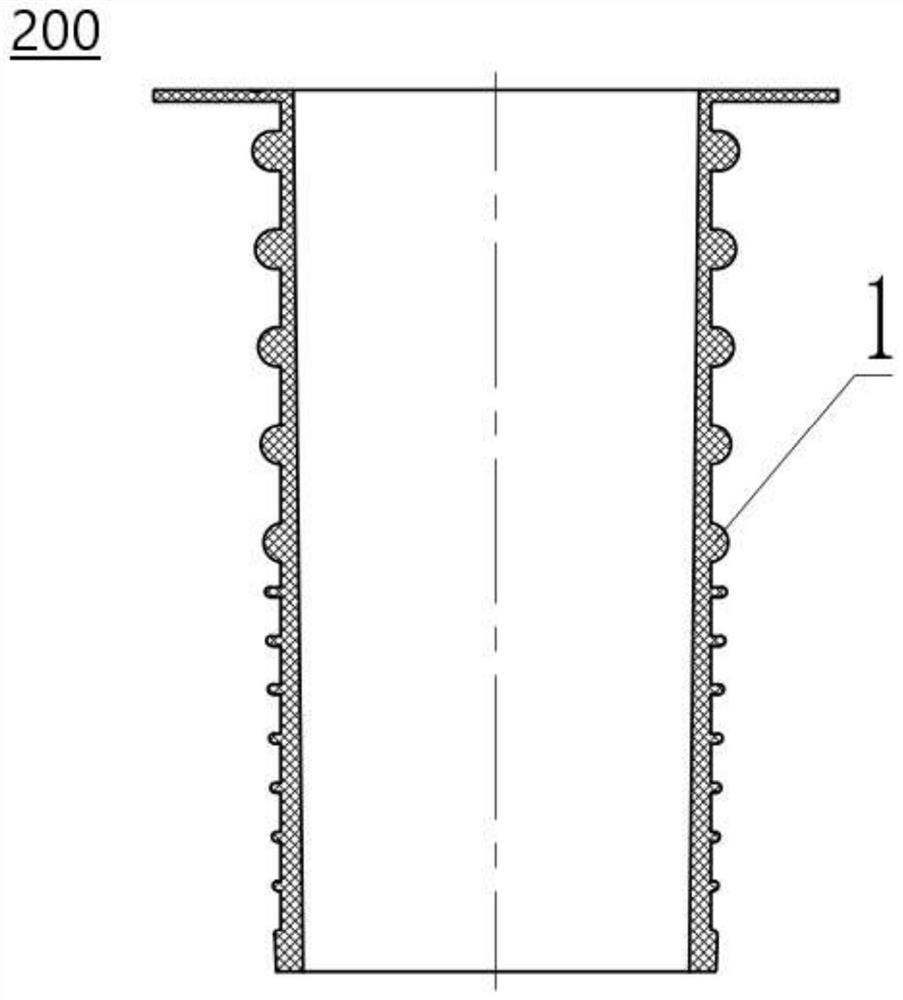

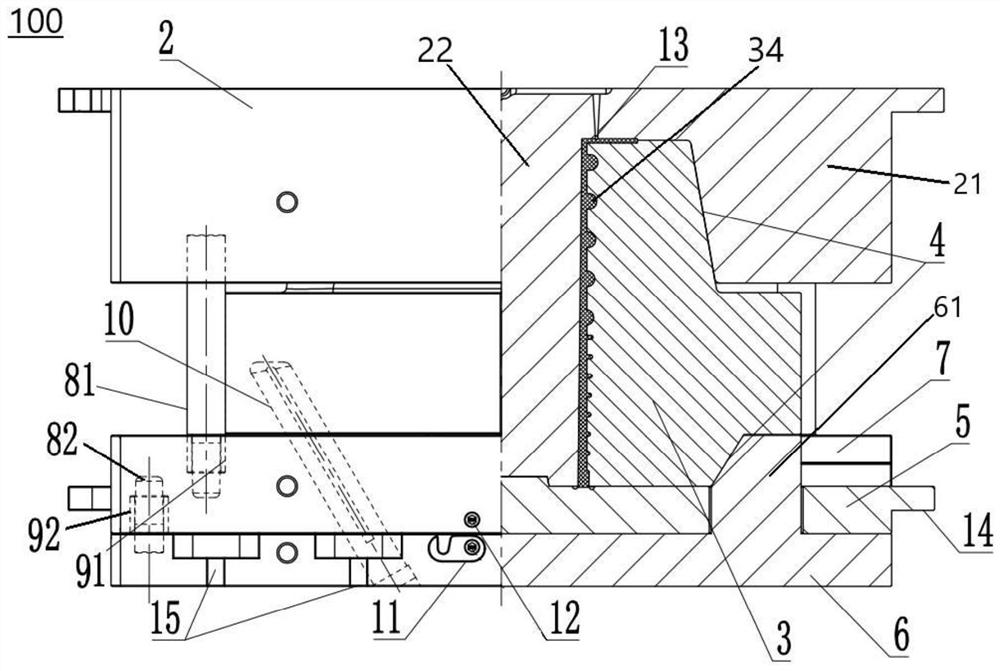

[0035] like Figure 1- Figure 4B As shown, the embodiment of the present invention provides a molding die 100, which can be used to form a rubber member 200 with a rib 1 ( figure 1 Indicated.

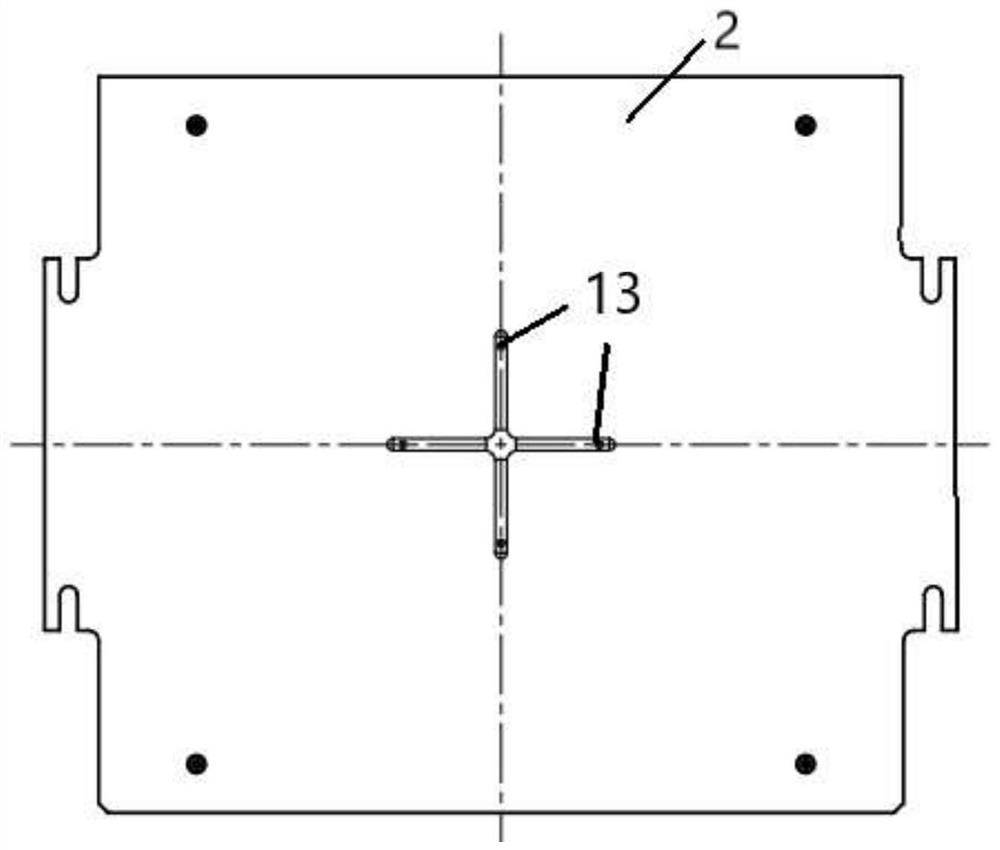

[0036] The molding die 100 can include a first template 2, a second template 5, and a molded body 3.

[0037] The first template 2 can be used as an upper template of the molding die 100, and the second template 5 may be provided as a lower template of the molding die, and is disposed below the first template 4. The first template 2 can move up and down with respect to the second template 5. For example, it may be that the first template 2 is held, and the second template 5 is moving close to or away from the first template 2. For example, it may be that the second template 5 is held, and the first template 2 moves close to or away from the second template 5.

[0038] The molded body 3 is disposed between the first template 2 and the second template 5. The molded body 3 has a through hole in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com