Plastic injection molding equipment for edible oil processing

An injection molding and edible oil technology, which is applied in the field of plastic injection molding equipment for edible oil processing, can solve the problems of inconvenient maintenance work, inconvenient taking of molding workpieces, and material cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

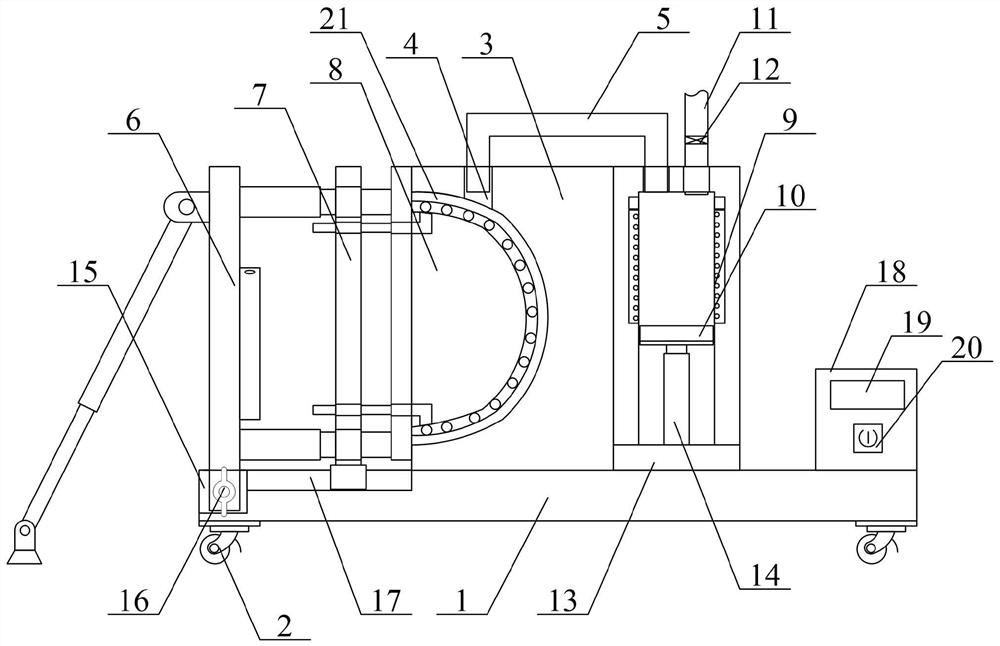

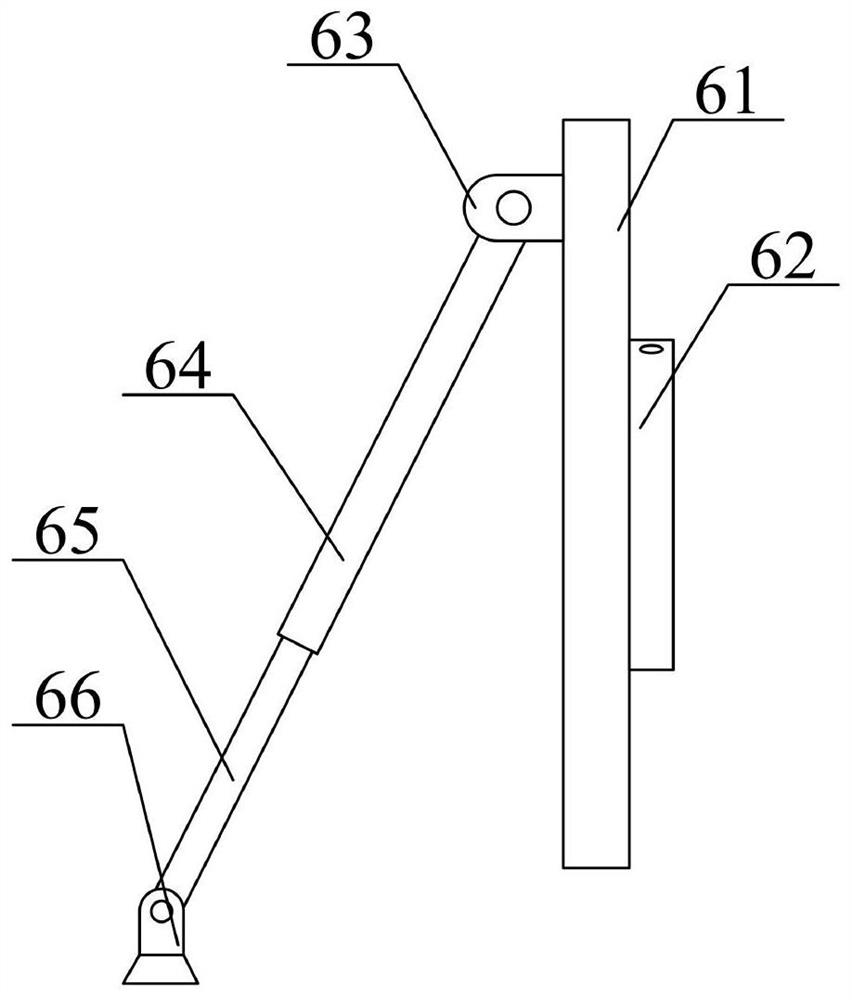

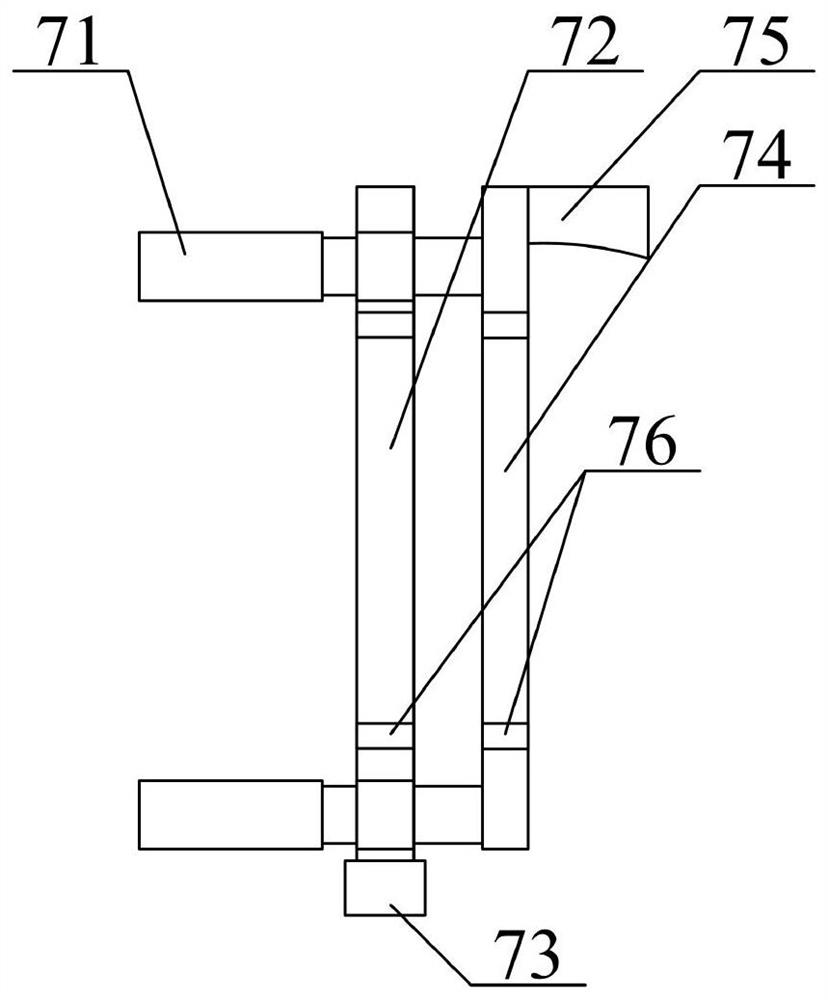

[0037] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, the plastic injection molding equipment for edible oil processing includes a movable base 1, a movable brake wheel 2, a fixed mold 3, an injection hole 4, an injection pipe 5, a rotatable support detection plate structure 6, and a supportable sliding top tight seat structure 7. Circular cooling movable seat structure 8, detectable heat preservation and heating barrel structure 9, pushing plate 10, feeding pipe 11, one-way valve 12, bottom cover 13, first electric push rod 14, insertion slot 15, lock Tighten the bolts 16, chute 17, control box 18, PLC19, power switch 20 and injection molding cavity 21, and the movable brake wheels 2 are respectively bolted to the four corners of the lower end of the mobile base 1; the fixed mold 3 is bolted to the Move the middle position of the upper end of the base 1; the injection hole 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com