Device for detecting fatigue resistance of spacer rubber pad

A detection device and spacer technology, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, can solve the problems of not being able to understand the physical properties of spacer rubber components well, and achieve safety issues and strengthen quality control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

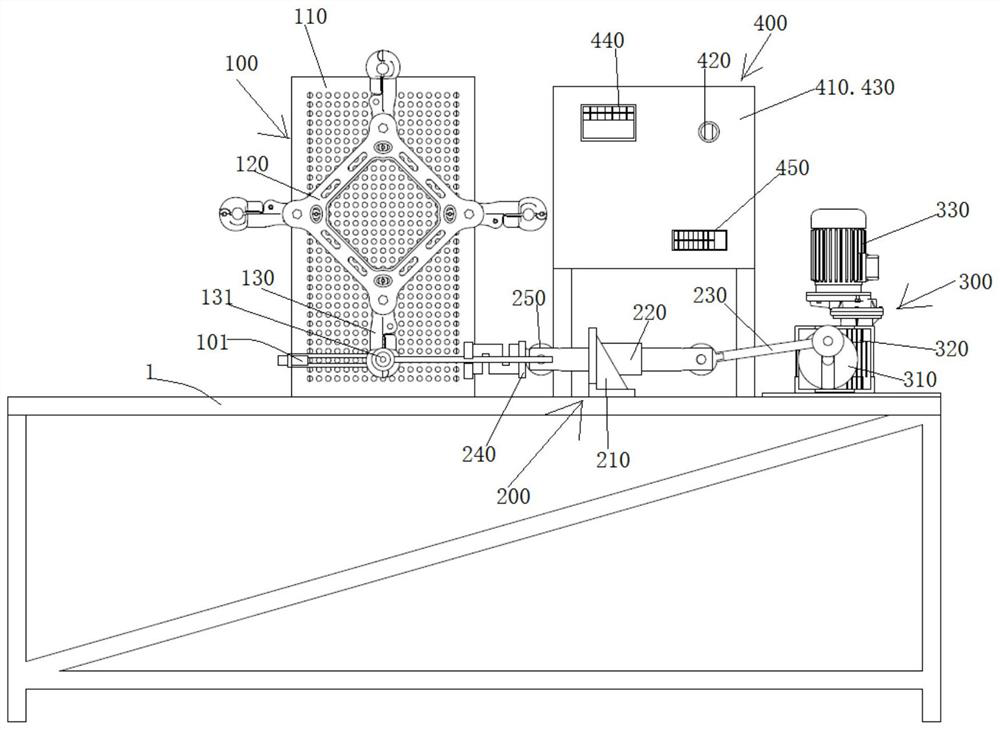

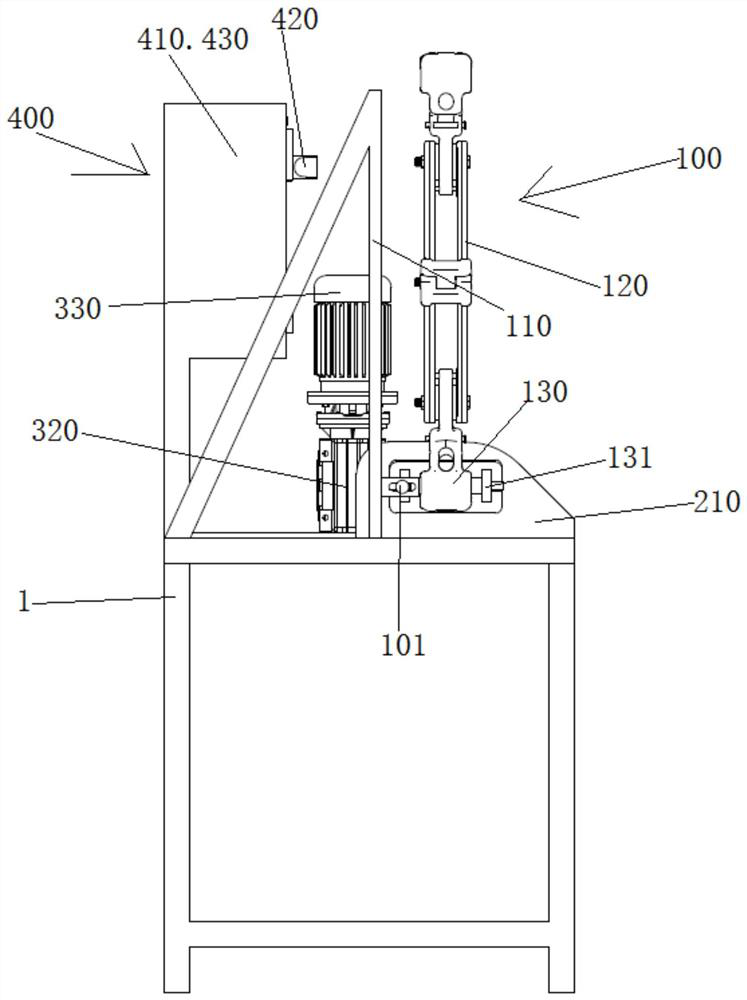

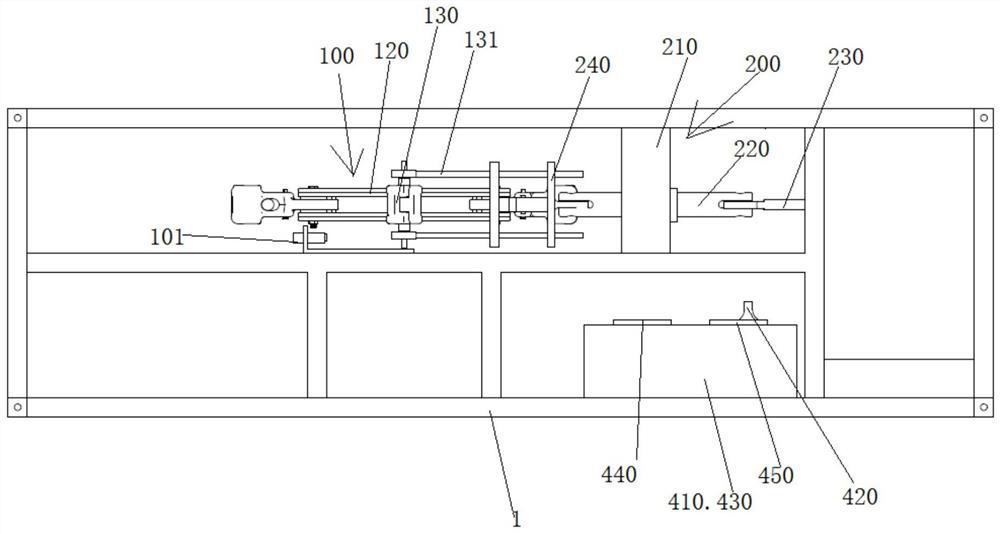

[0026] see Figure 1 to Figure 4 A detection device for anti-fatigue of spacer rubber pads is shown, including a workbench 1 , a detection unit 100 , a transmission unit 200 , a power unit 300 and a control unit 400 . Specifically, a detection unit 100 , a transmission unit 200 , a power unit 300 and a control unit 400 are sequentially arranged on the workbench 1 from left to right.

[0027] The detection unit 100 is arranged on the workbench 1 and is used for placing rubber components. The detection unit 100 is provided with a counting sensor 101 for detecting the number of swings. The detection unit 100 includes a porous panel 110 arranged on the workbench 1 and a porous The spacer rod connecting frame 120 on the panel 110 and the spacer rod chuck 130 hinged with the spacer rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com