Feed processing and screening device

A screening device and feed processing technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of feed waste and low screening efficiency, and achieve the effect of accelerating screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

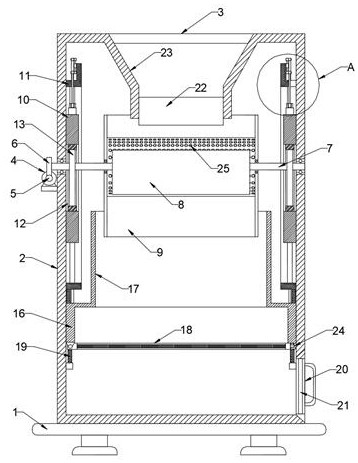

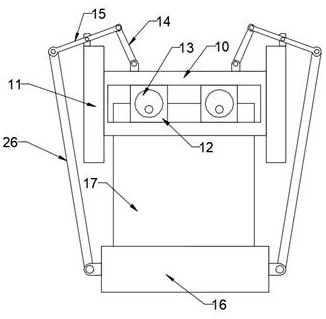

[0054] When the whole device is put into use, first put the feed that needs to be screened into the box body 2, and when the rotating motor 4 starts to work, the meshing of the worm 5 and the worm wheel 6 will drive the two rotating shafts 7 to rotate, and the rotating shaft 7 will rotate During the grinding process, the two crushing rollers 8 mounted eccentrically on their side walls will be driven to rotate. When the crushing rollers 8 rotate, the size of the gap between the side walls of the crushing rollers 8 and the inner wall of the grinding holder 9 will change continuously. , when the gap becomes larger, the larger feed block falls into the gap between the crushing roller 8 and the grinding fixed seat 9, and during the rotation of the crushing roller 8, the gap gradually becomes smaller so that the feed block is squeezed and crushed ;

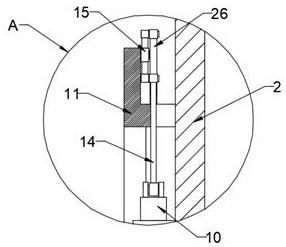

[0055] Simultaneously when the rotating shaft 7 rotates, the rotating block 13 installed on its side wall eccentrically will drive the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com