A road traffic guardrail forming device and method

A technology for road traffic and forming devices, applied to road safety devices, roads, roads, etc., can solve problems such as forming deviation and poor forming quality, reduce manufacturing costs, improve forming quality, and avoid bending deviation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

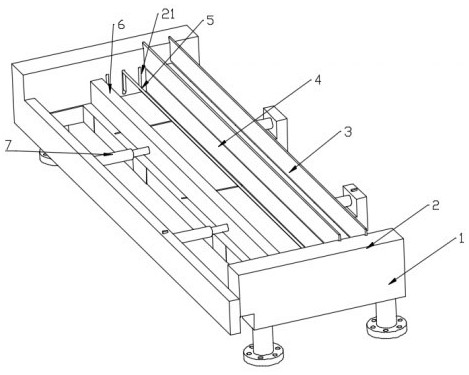

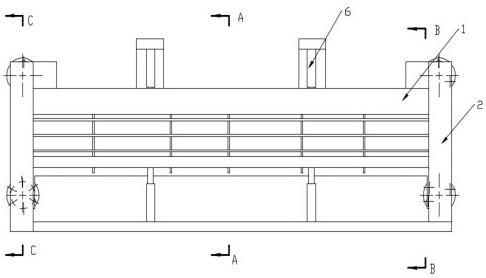

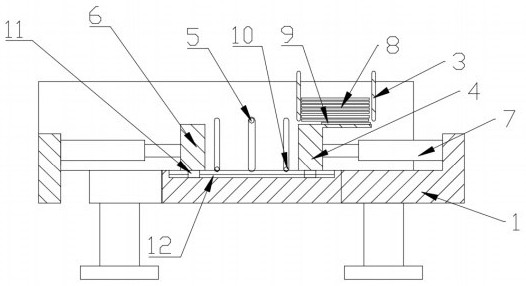

[0037] refer to Figure 1~Figure 4 In this embodiment, a road traffic guardrail forming device is proposed, which is used to extrude a flat plate 8 to form a corrugated plate. The road traffic guardrail forming device includes a workbench 1, a flat plate groove 3, a second A squeeze plate 4, a second squeeze plate 6 and a hydraulic rod 7.

[0038] The workbench 1 forms a working platform. The workbench 1 may be a rectangular plate structure, and the length of the workbench 1 is greater than or equal to the length of the plane plate 8 . The four corners of the bottom of the workbench 1 are provided with support legs, and the bottom of the support legs is fixedly connected with a backing plate, and the support legs support the workbench 1 to a specified height, and the setting of the backing plate increases the stability of the support of the support legs. A first extruding plate 4 and a second extruding plate 6 are provided for relative sliding on the workbench 1 . It is used...

Embodiment 2

[0043] refer to Figure 4 , Image 6 , The pulling material includes a transmission rack 13 , a drive rack 14 , a drive gear 15 and a driven gear 16 . Drive rack 14 is slidably arranged in the inside of workbench 1, and one end of drive rack 14 is fixedly connected on the second extruding plate 6, and the inside of workbench 1 is connected with driving gear 15 and driven gear 16, and drive gear 15 It is fixedly connected with the driven gear 16 coaxially. The diameter of the driving gear 15 is smaller than the diameter of the driven gear 16. The inside of the workbench 1 is provided with a pulling groove. The end of the pulling groove away from the first extrusion plate 4 is an open structure. A cover is provided. The transmission rack 13 is slidably nested inside the pulling groove, and the end of the transmission rack 13 is rotated by a reset member to be provided with a pull rod 24, which is close to one end of the first extruding plate 4, and the reset member makes the ...

Embodiment 3

[0045] refer to Figure 9 , the present invention also provides a road traffic guardrail forming method, using the above-mentioned a kind of road traffic guardrail forming device, the specific steps of the road traffic guardrail forming method are as follows:

[0046] The first extruding plate 4 and the second extruding plate 6 slide away from each other, the support plate 9 slides out from the bottom of the plane plate groove 3, and the plane plate 8 falls on the first extruding plate 4 under gravity.

[0047] The second extruding plate 6 enables the pulling member to pull the corrugated plate on the workbench 1 out of the workbench 1 and discharge it from the discharge through groove.

[0048] The first extruding plate 4 and the second extruding plate 6 slide close together, the planar plate 8 is separated from the bottom of the planar plate groove 3, and the planar plate 8 falls between the first extruding plate 4 and the second extruding plate 6 under gravity, And between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com