Processing method of heavy-duty herringbone gear and its calibration tooling

A technology of herringbone teeth and ring gears, which is applied in metal processing equipment, gear tooth manufacturing devices, gear teeth, etc., can solve problems such as moderate control deviation and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

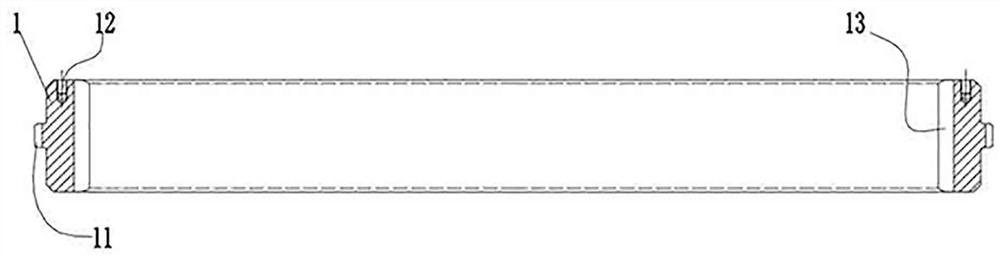

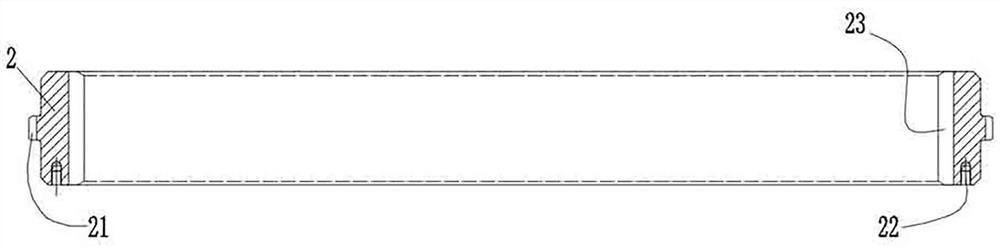

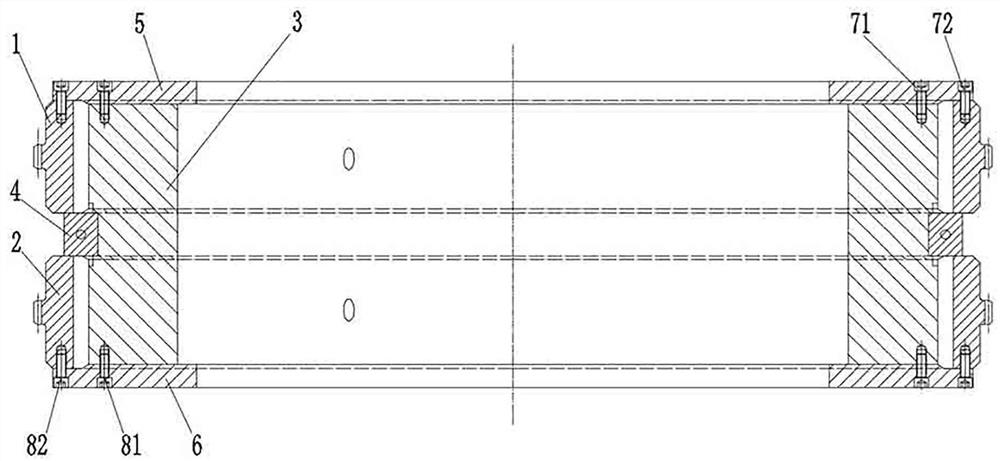

[0042] Such as Figure 3 to Figure 8A calibration tool for a heavy-duty herringbone gear for split split processing shown, including a calibration piece 3, a positioning piece 4, a first pressing piece 5, a second pressing piece 6 and two calibration probe rods 9. The correction part 3 is cylindrical, and the positioning part 4 is in the shape of a ring and protrudes from the outer peripheral surface of the correction part 3. The correction part 3 is provided with two radial holes 32, and the two radial holes 32 The axes are all perpendicular to the axis of the correction piece 3 and are located in the same radial plane of the correction piece 3, and the two radial holes 32 are respectively located on the upper and lower sides of the positioning piece 4 and the distance from the two to the positioning piece 4 is equal; The hole 32 runs through the cylinder wall of the correction member 3 from the inside to the outside, and the correction probe rod 9 is inserted into the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com