Internal and external tooth centering control structure and machining method of high-speed precise heavy-load herringbone gear ring

A processing method and a technology of internal and external teeth, which are applied to gear tooth manufacturing devices, manufacturing tools, components with teeth, etc., can solve problems such as moderate control deviation and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

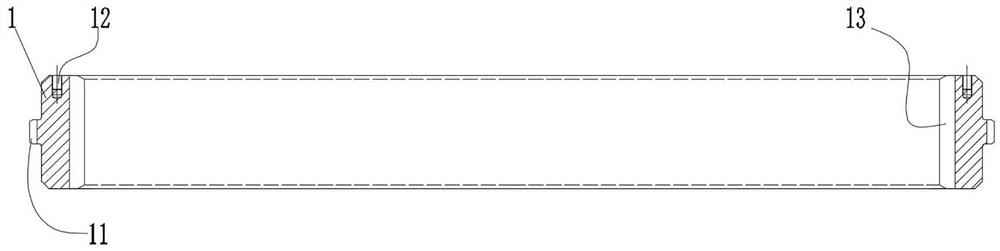

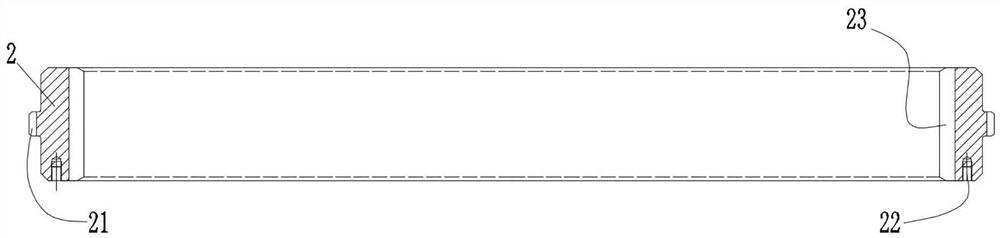

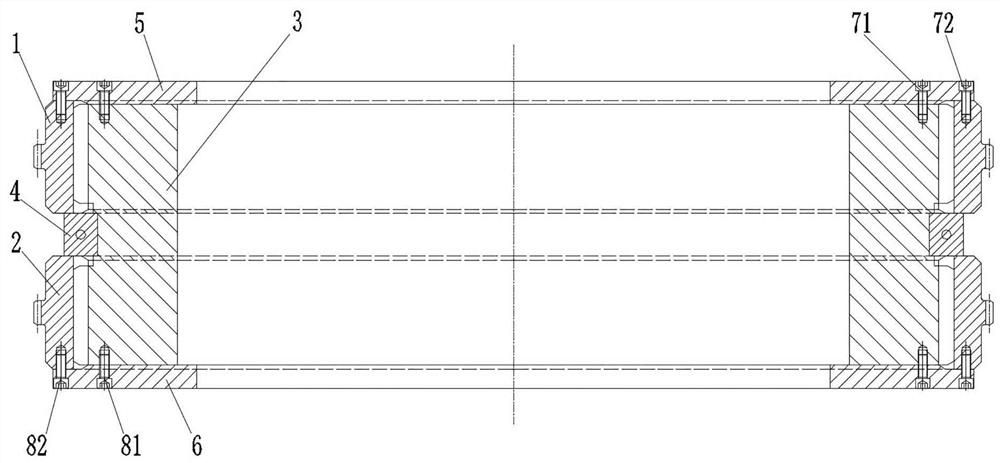

[0044] A centering control processing method of internal and external teeth of a high-speed precision heavy-duty herringbone ring gear, including a first ring gear 1, a second ring gear 2 and a correction tool; the correction tool includes a correction part 3, a positioning part 4, a first pressing Part 5 and the second pressing part 6, such as image 3 and Figure 4 As shown, a first helical tooth 32 and a second helical tooth 33 are provided on the outer peripheral surface of the correcting member 3, the first helical tooth 32 and the second helical tooth 33 cooperate to form a herringbone tooth structure, and the positioning member 4 is sleeved on the correcting member 3 and between the first helical tooth 32 and the second helical tooth 33; the specific steps are as follows:

[0045] Step 1), complete the grooving, heat treatment and grinding of the internal helical teeth of the first ring gear 1 and the second ring gear 2 respectively; where one end face of the first rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com