Conveying assembly for hidden quick-assembly mechanism full-automatic assembling machine

A fully automatic and hidden technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as affecting the efficiency of assembly and consuming the labor intensity of operators, so as to improve work efficiency, avoid repeated handling, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the linear drive mechanism 2 is a hydraulic telescopic cylinder;

Embodiment 2

[0026] Embodiment two: the linear drive mechanism 2 cylinders;

Embodiment 3

[0027] Embodiment three: the linear drive mechanism 2 is an electric push rod;

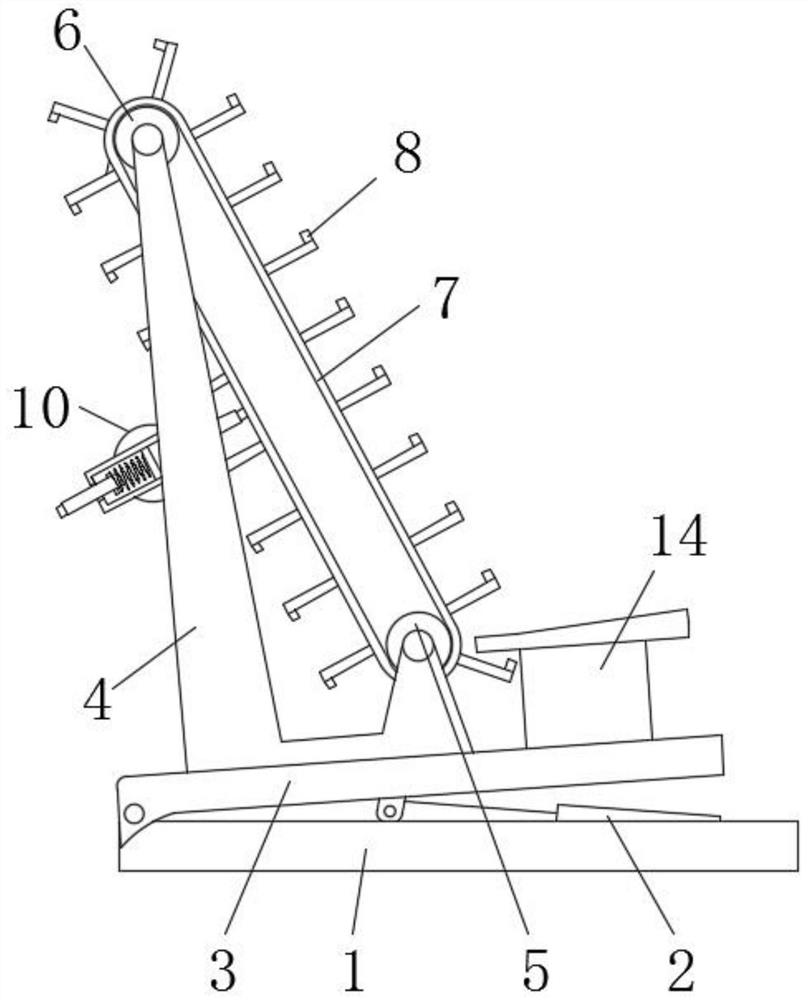

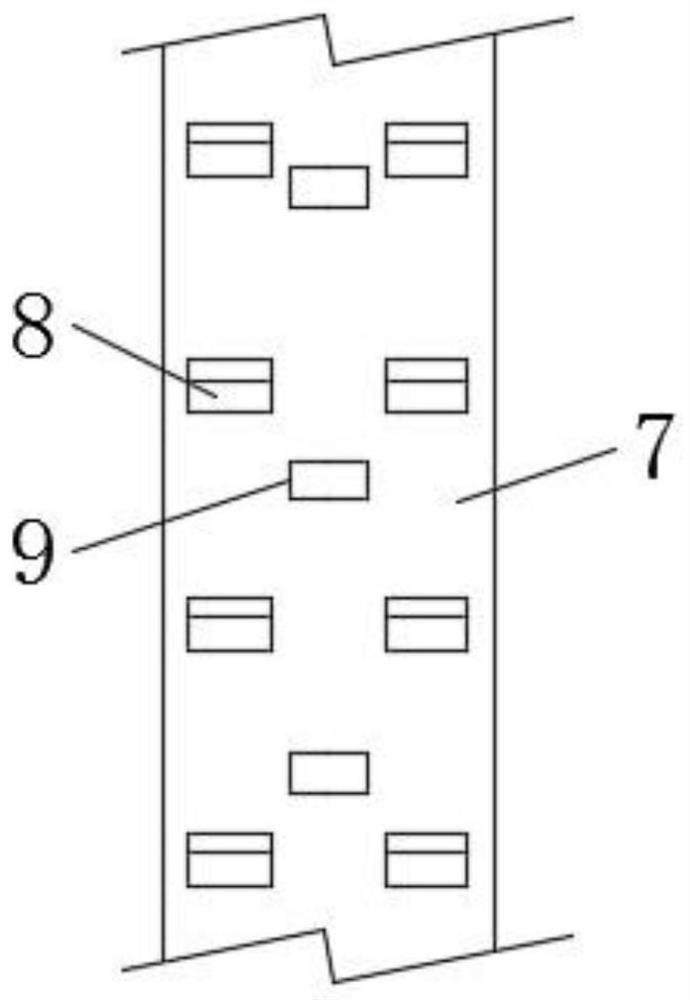

[0028] A mounting frame 4 is fixed on the supporting plate 3, and a first driving roller 5 and a second driving roller 6 are mounted on the mounting frame 4 for rotation, and a conveyor belt 7 is wound and connected between the first driving roller 5 and the second driving roller 6, The conveyor belt 7 is arranged obliquely, and a plurality of dials 8 are evenly arranged on the conveyor belt 7. The middle part of the dial 8 is provided with a slot, and a limit bar is arranged on one side of the outer end of the dial 8. The limit bar is located at the bottom of the dial 8 On the same side, and the conveyor belt 7 is provided with a plurality of through holes 9, and the through holes 9 are arranged linearly;

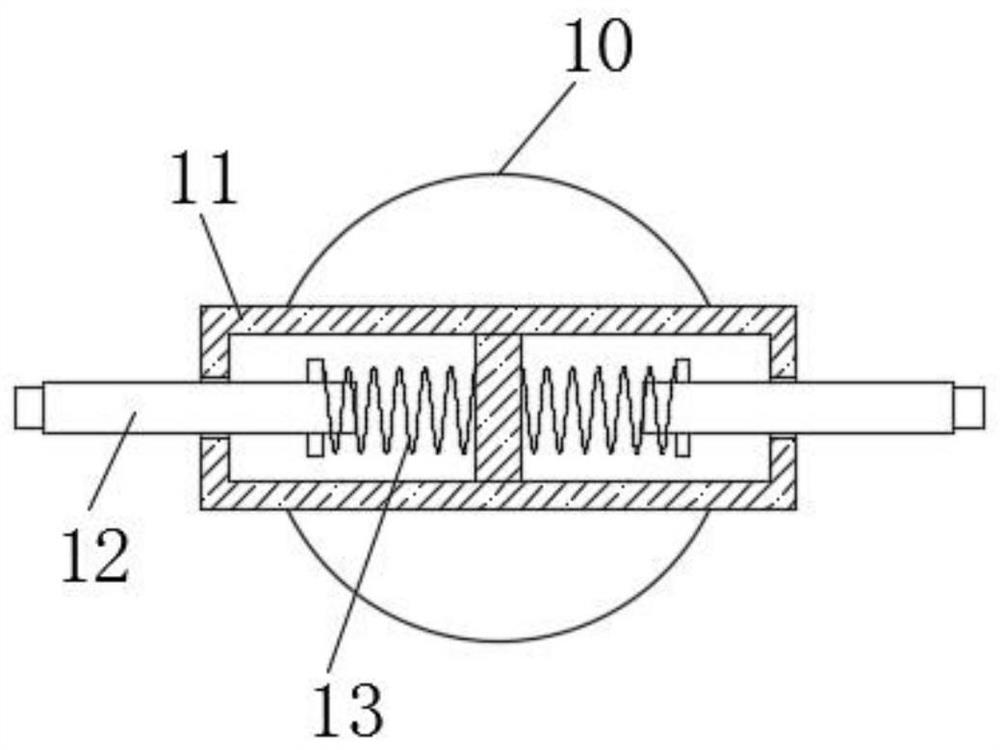

[0029] The mounting frame 4 is rotatably equipped with a turntable 10, the mounting frame 4 is fixed with a drive motor, the output shaft of the drive motor is fixed concentrically with the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com