Feeding mechanism of edge covering die

A material feeding and mold technology, applied in the field of hemming mold feeding mechanism, can solve the problems of long motion stroke, long motion track, difficult operation, etc., achieve high feeding accuracy, reduce work burden, and improve pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

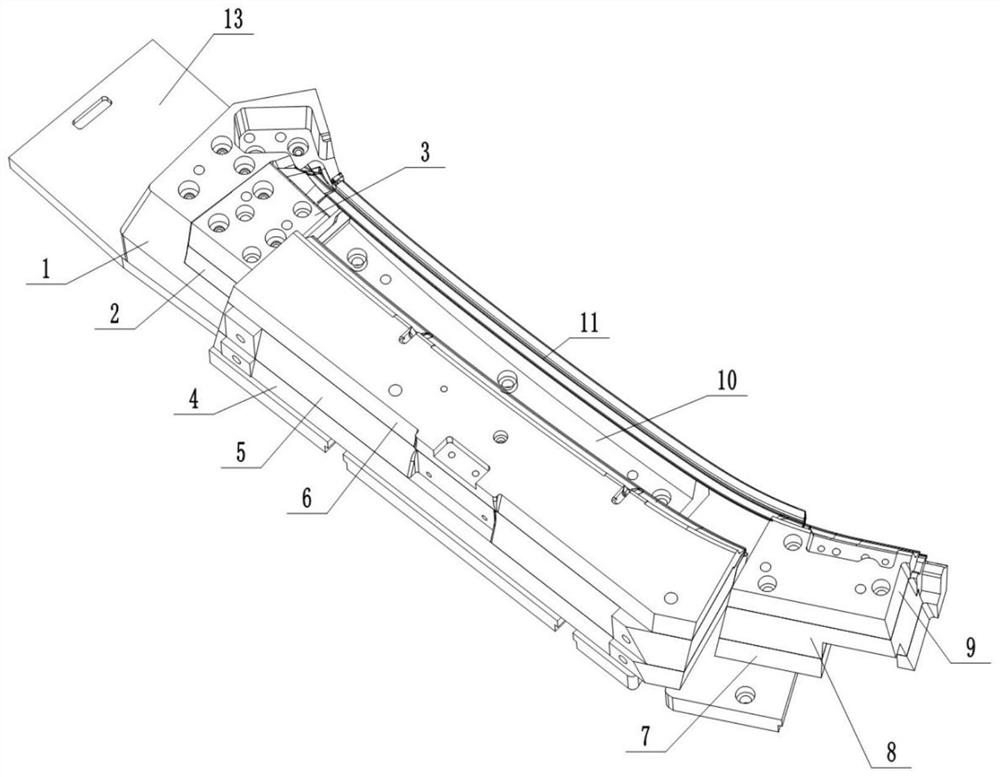

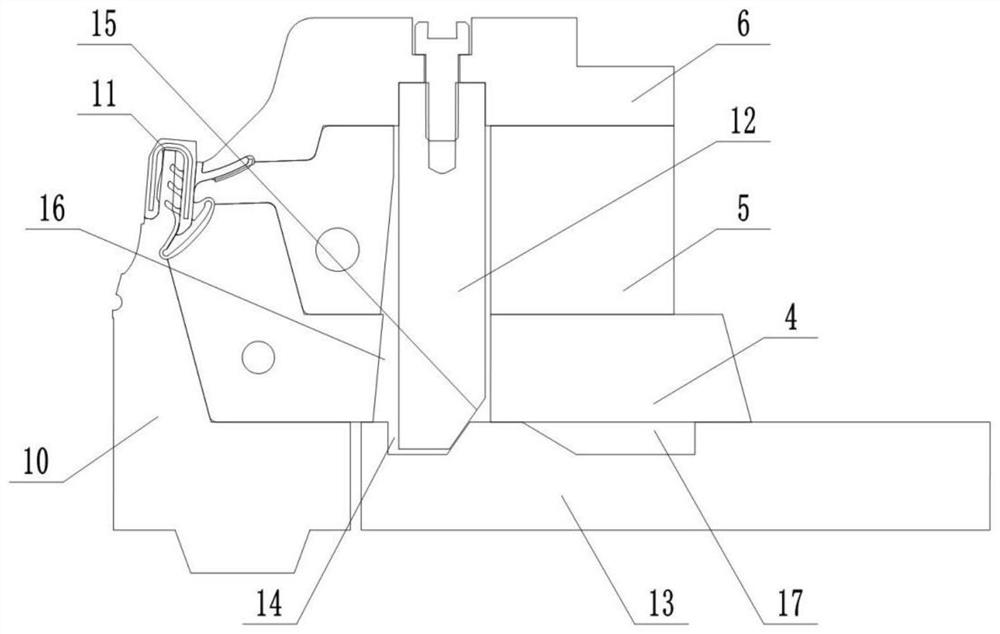

[0018] Such as Figure 1 to Figure 2 As shown, a feeding mechanism for the hemming mold includes a first end feeding assembly, an intermediate feeding assembly, a second end feeding assembly and a bottom plate 13, and the intermediate feeding assembly is located between the first end feeding assembly and the first end feeding assembly. Between the second end feeding components, the injection cavity of the first end feeding component, the middle feeding component and the second end feeding component are connected as a whole, the first end feeding component, the middle feeding The feed assembly and the second end feed assembly are installed on the base plate 13;

[0019] The intermediate feeding assembly includes the No. 4 cavity part 4 slidingly connected to the top surface of the bottom plate 13 and the No. 10 cavity part 10 fixed on the bottom plate 13. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com