Full-automatic remains transfer system and fixed roller conveying belt thereof

A technology for fixing rollers and conveyor belts, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problems of low safety and convenience, avoid loss of remains, good storage and recording, and solve safety problems. less sex and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

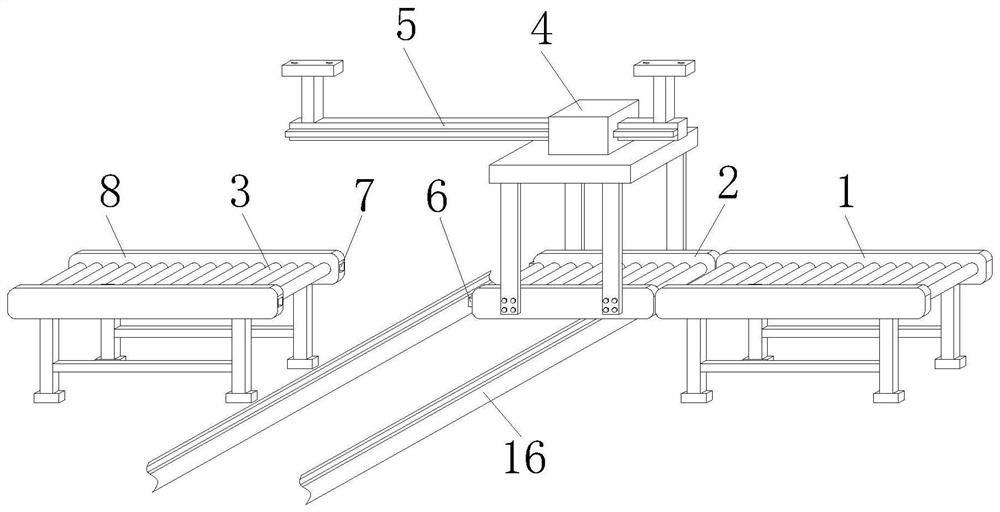

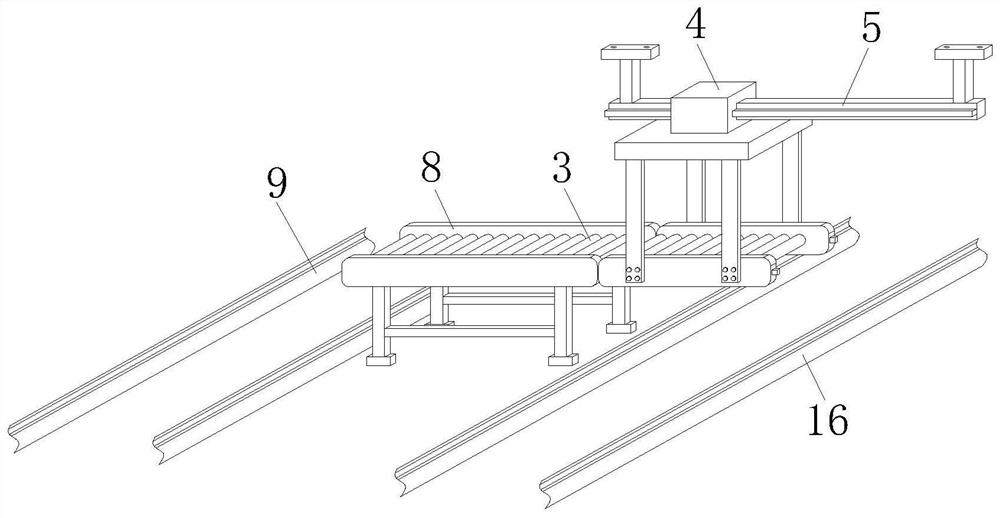

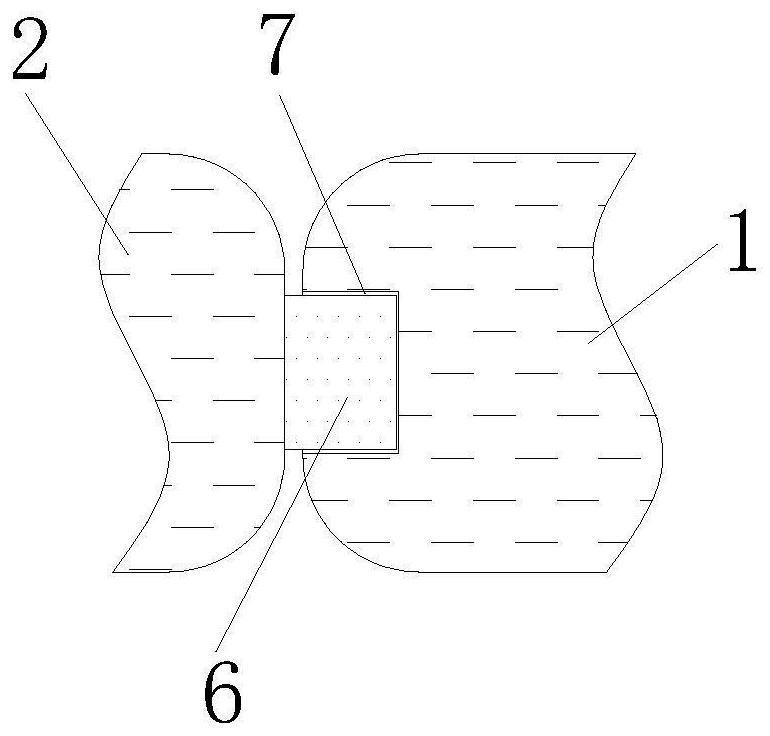

[0039] see Figure 1-8 As shown, a fully automatic body transfer system includes a frost-free refrigerator, an intelligent rail car, a fixed roller conveyor belt, a moving roller conveyor belt 2, a replacement area, and a central control communication transmission system. The fixed roller conveyor belt includes A fixed roller conveyor belt Belt 1 and B fixed roller conveyor belt 8, between A fixed roller conveyor belt 1 and B fixed roller conveyor belt 8, there is a moving roller conveyor belt 2, and the top of the moving roller conveyor belt 2 is slidably connected with the guide rail 5 through the moving block 4, The guide rail 5 is fixed on the wall or the mounting frame by bolts, A fixed roller conveyor belt 1, a moving roller conveyor belt 2 and B fixed roller conveyor belt 8 are equidistantly provided with a plurality of roller bodies 3, A fixed roller conveyor belt A track 16 is fixed on the ground between 1 and B fixed roller conveyor belt 8, and B track 9 is fixed on ...

specific Embodiment approach 2

[0055] The following is an embodiment of a fixed roller conveyor belt of a fully automatic body transfer system. The fixed roller conveyor belt can be implemented alone or as a key structure of a fully automatic body transfer system disclosed in the first embodiment.

[0056] see Figure 1-8 As shown, a fully automatic body transfer system includes a frost-free refrigerator, an intelligent rail car, a fixed roller conveyor belt, a moving roller conveyor belt 2, a replacement area, and a central control communication transmission system. The fixed roller conveyor belt includes A fixed roller conveyor belt Belt 1 and B fixed roller conveyor belt 8, between A fixed roller conveyor belt 1 and B fixed roller conveyor belt 8, there is a moving roller conveyor belt 2, and the top of the moving roller conveyor belt 2 is slidably connected with the guide rail 5 through the moving block 4, The guide rail 5 is fixed on the wall or the mounting frame by bolts, A fixed roller conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com