Water-based nanosheet composite coating as well as preparation method and application thereof

A composite coating and nanosheet technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as inability to protect metal substrates, accelerated penetration, lack of efficient dispersion of water-based epoxy coatings, and achieve good physical barrier effect. , Guarantee the effect of isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] An embodiment of the water-based nano-sheet composite coating and its preparation method and application of the present invention, the preparation method of the water-based nano-sheet composite coating comprises the following steps:

[0039] (1) Add 75 mg of boron nitride powder, a two-dimensional nanosheet material with a size of 0.5 to 50 μm, and 0.1 g of urushiol derivatives into 2.5 g of deionized water, and obtain a boron nitride nanosheet dispersion after ultrasonic treatment for 4 hours;

[0040] (2) Add 10g WTE-51 type water-based epoxy resin in the nanosheet dispersion, and make it stir evenly by mechanical stirring; finally add 5Gwh115 type polyamide curing agent, put it into the defoamer quickly after stirring for 5 minutes, Set the rotation speed to 1500r / min, vacuum degree to 95.8kPa and defoam for 15min to obtain the water-based nanosheet composite coating.

[0041] The metal product used in this example is a Q235 carbon steel sheet with a specification of...

Embodiment 2

[0047] An embodiment of the water-based nano-sheet composite coating and its preparation method and application in the present invention, the difference between this embodiment and Example 1 is that the two-dimensional nano-sheet material is graphene with a size of 0.5-50 μm.

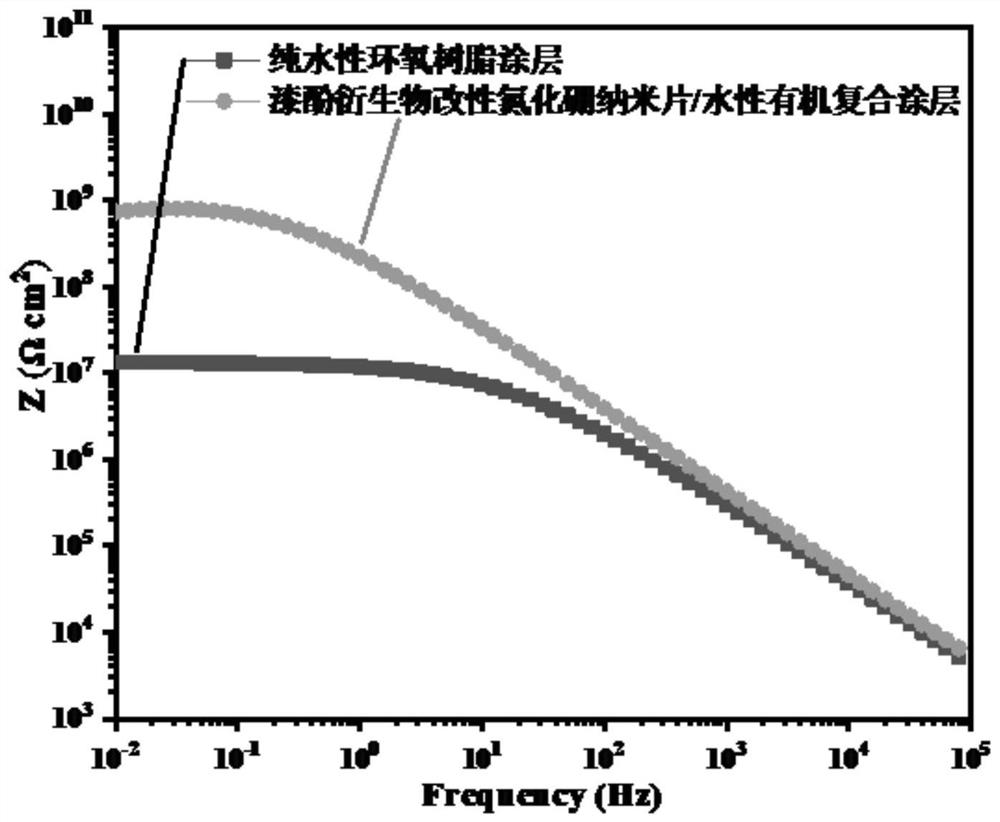

[0048] Application and testing are carried out to the water-based nanosheet composite coating obtained in the present embodiment, and the application and testing method are the same as in Example 1, and the test results are as follows: figure 2 shown.

[0049] From figure 2 It can be seen that the coating of pure waterborne epoxy resin coating is soaked in 3.5wt% NaCl aqueous solution for 15 days |Z| f=0.01Hz 1.33×10 7 Ω·cm 2 , Urushiol derivative-modified boron nitride nanosheets / waterborne composite coating after soaking in 3.5wt% NaCl aqueous solution for 15 days |Z| f=0.01Hz is 1.77×10 8 Ω·cm 2 , significantly improving the corrosion resistance of the coating.

Embodiment 3

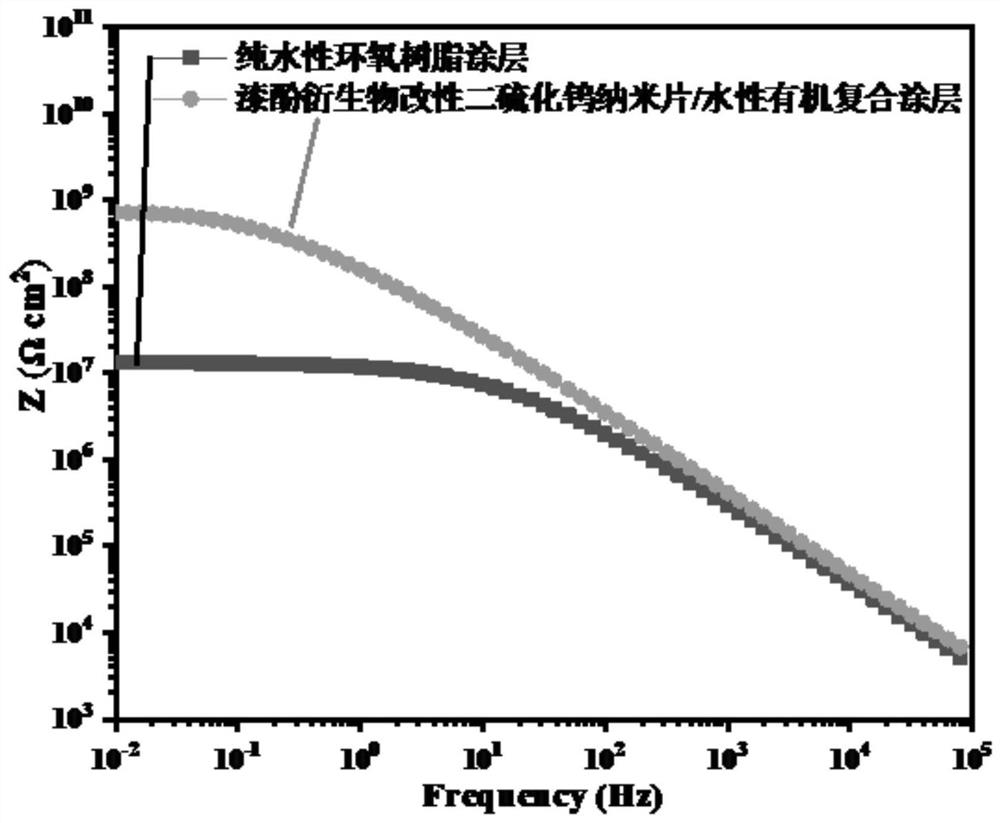

[0051] An embodiment of the water-based nano-sheet composite coating of the present invention and its preparation method and application, the difference between this embodiment and Example 1 is that the two-dimensional nano-sheet material is tungsten disulfide with a size of 0.5-50 μm .

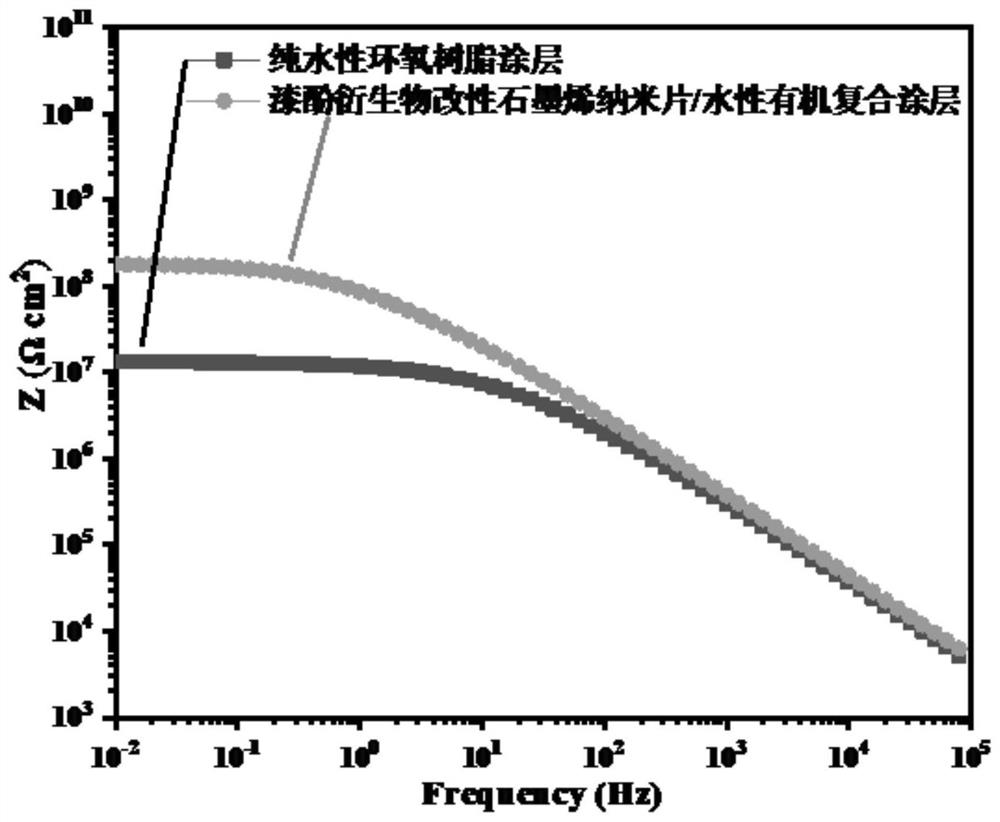

[0052] Application and testing are carried out to the water-based nanosheet composite coating obtained in the present embodiment, and the application and testing method are the same as in Example 1, and the test results are as follows: image 3 shown.

[0053] From image 3 It can be seen that the coating of pure waterborne epoxy resin coating is soaked in 3.5wt% NaCl aqueous solution for 15 days |Z| f=0.01Hz 1.33×10 7 Ω·cm 2 , Urushiol derivative-modified boron nitride nanosheets / waterborne composite coating after soaking in 3.5wt% NaCl aqueous solution for 15 days |Z| f=0.01Hz is 7.08×10 8 Ω·cm 2 , significantly improving the corrosion resistance of the coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com