Sawtooth-feeling-free integrated narrowing and widening knitting process, fabric and vamp

An integrated, sawtooth technology, applied in knitting, weft knitting, shoe uppers, etc., can solve problems such as reducing the texture of the upper, achieve the effect of improving diversity and solving sawtooth defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

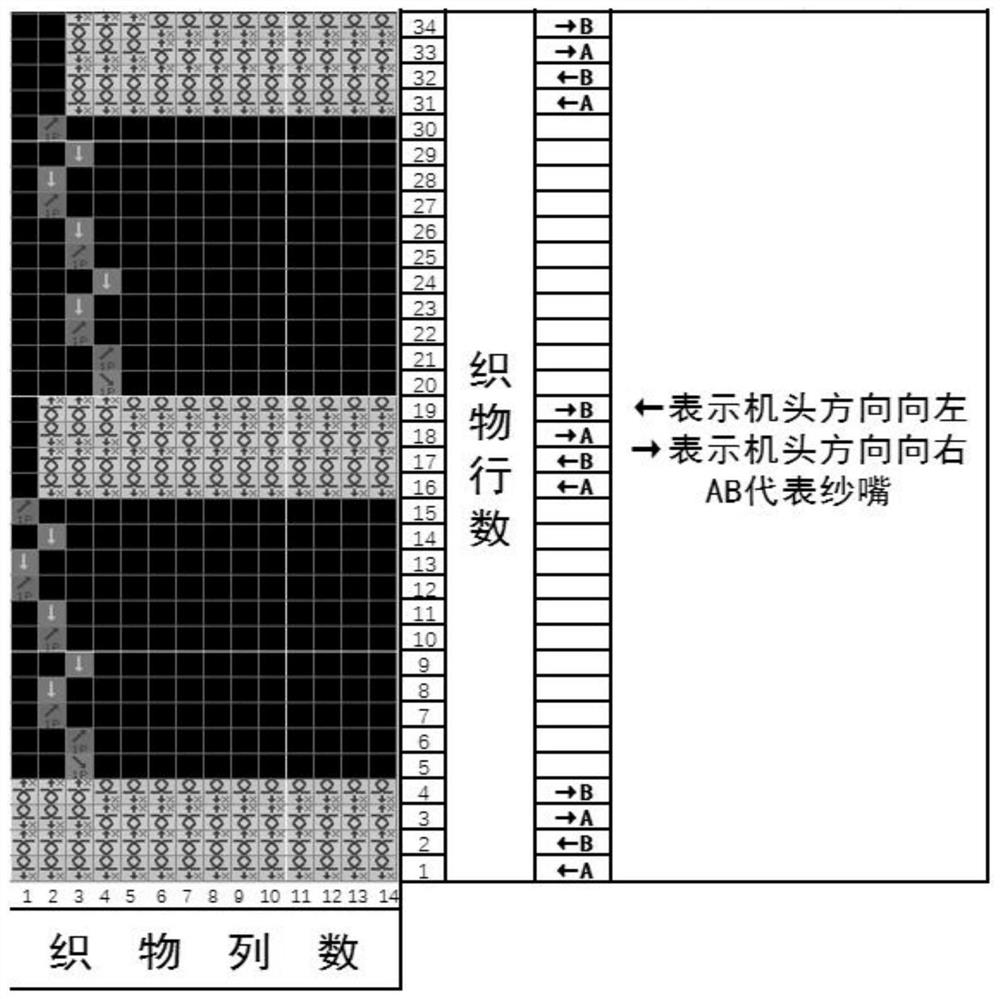

[0031] Embodiments according to the present invention will now be described in detail with reference to the accompanying drawings.

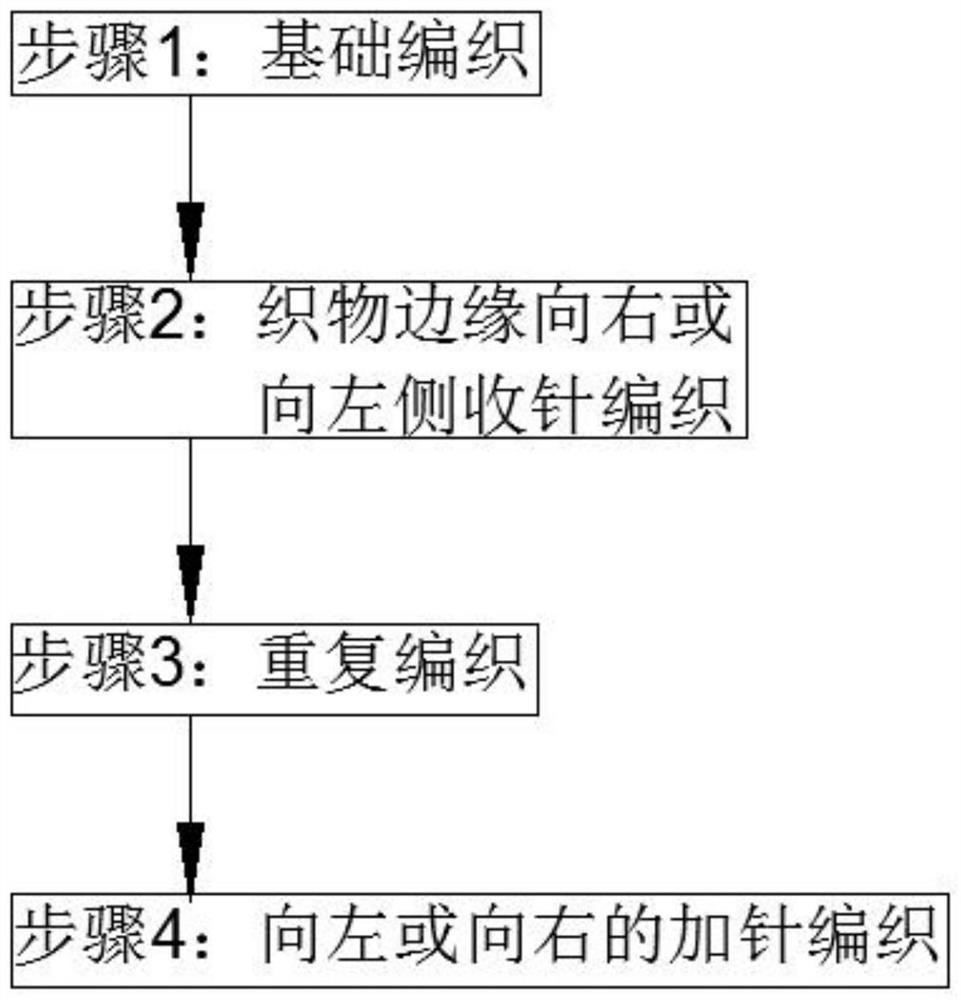

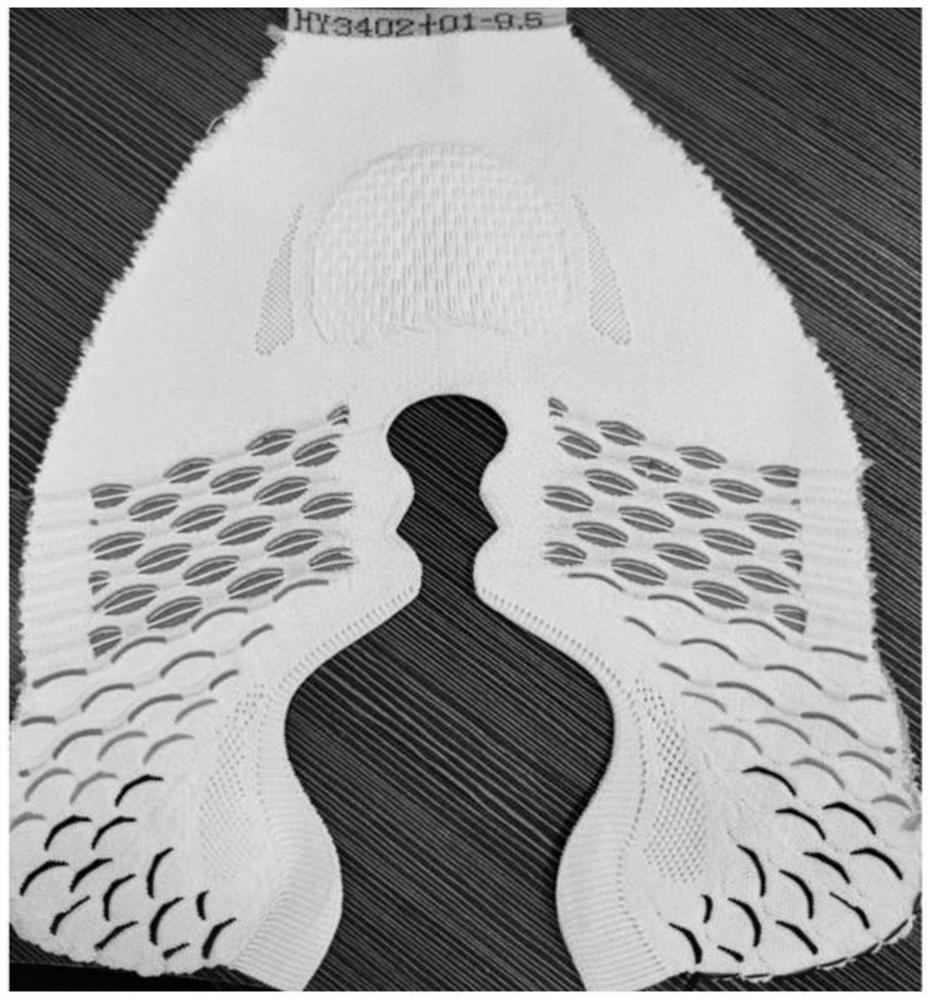

[0032] A non-sawtooth integrated narrowing and extra-needle knitted fabric, which utilizes the functions of the fly knitting knitting machine and the function of the yarn to knit at one time, including the fabric body and the needles between the edges of two adjacent knitting rows. The number of positions is 1 needle position, and the fabric body is woven with polyester high-elastic yarn into a double-layer braided layer structure with a top layer and a bottom layer. The specific weaving steps are as follows:

[0033] refer to Figure 1 to Figure 5 , A and B yarns are polyester high elastic yarns.

[0034] The first weaving row is A yarn for bottom knitting.

[0035] The second weaving row is B yarn for face knitting.

[0036] The third knitting row is A yarn for top knitting, and the left 3 knitting rows for bottom knitting.

[0037] The fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com