Method for separating attitude angle error of inertial measurement system based on centrifugal machine excitation

An inertial measurement and error separation technology, which is applied in the aviation field of aerospace and high-precision inertial navigation, can solve the problems that cannot meet the error separation of inertial devices, and achieve the effect of improving confidence, high reliability, and reducing index requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0116] In order to illustrate the inertial measurement system error separation method based on the large overload excitation of the centrifuge provided by the present invention, the preferred embodiment is:

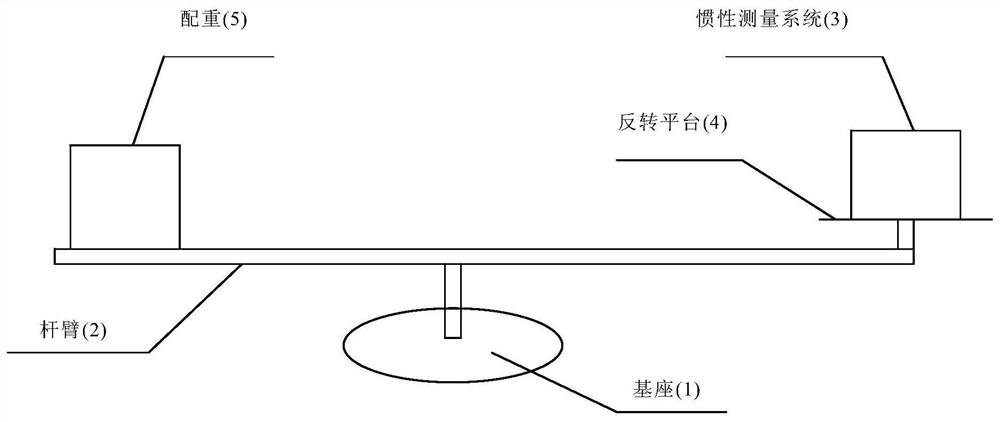

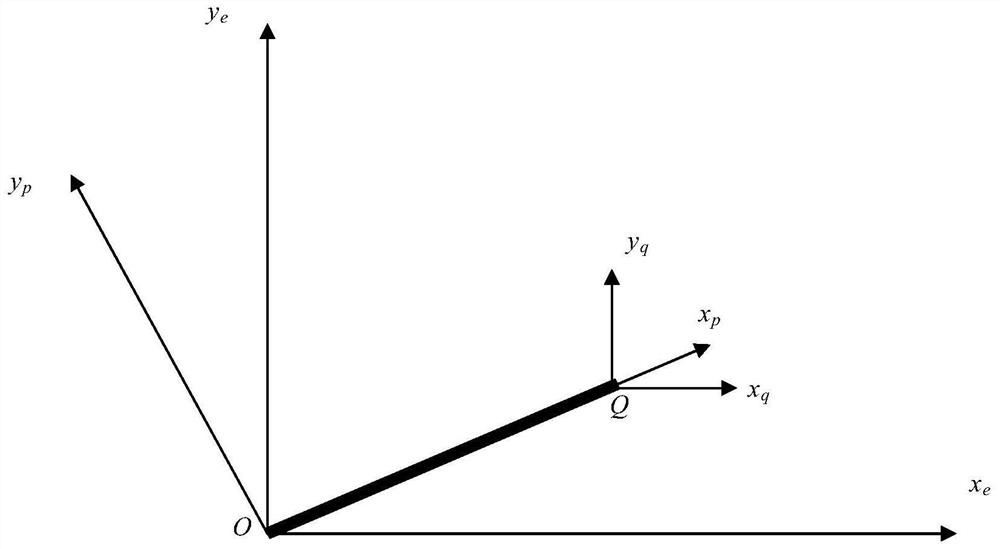

[0117] Suppose the arm length of the centrifuge is 2R=6m, and the inertial measurement system is placed on the reverse platform of the centrifuge, such as figure 1 shown. The relationship among centrifuge base, lever arm and inverted platform coordinate system is as follows: figure 2 shown.

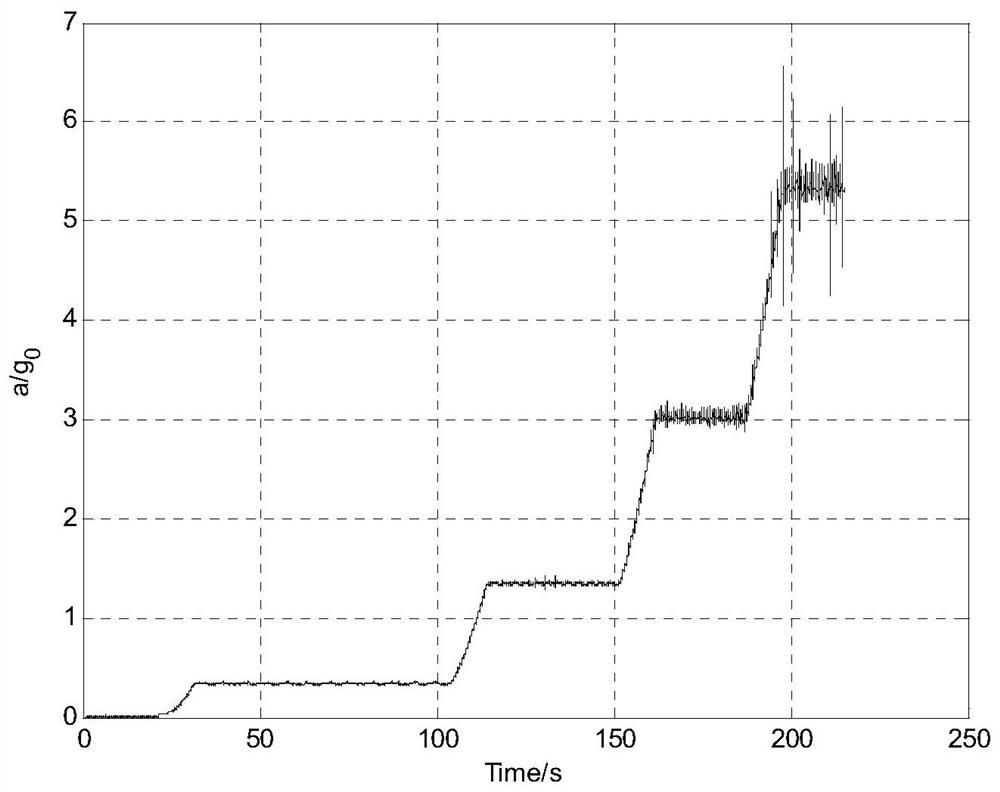

[0118] In a certain test, the sampling time of the rotation angle of the centrifuge is ΔT=0.02s, the running time is 215s, and the total number of data N=10750. The centripetal acceleration during rotation is as image 3 shown.

[0119] Attitude angle φ after navigation solution x Such as Figure 4 shown, but the measured platform system frame angle ψ x output as Figure 5 As shown, the error value δφ of the two x = φ x -ψ x Such as Figure 6 As shown, it can be seen tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com