Steel product surface defect detection method based on model compression

A defect detection and model technology, applied in neural learning methods, biological neural network models, character and pattern recognition, etc., to reduce resource occupancy and improve detection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

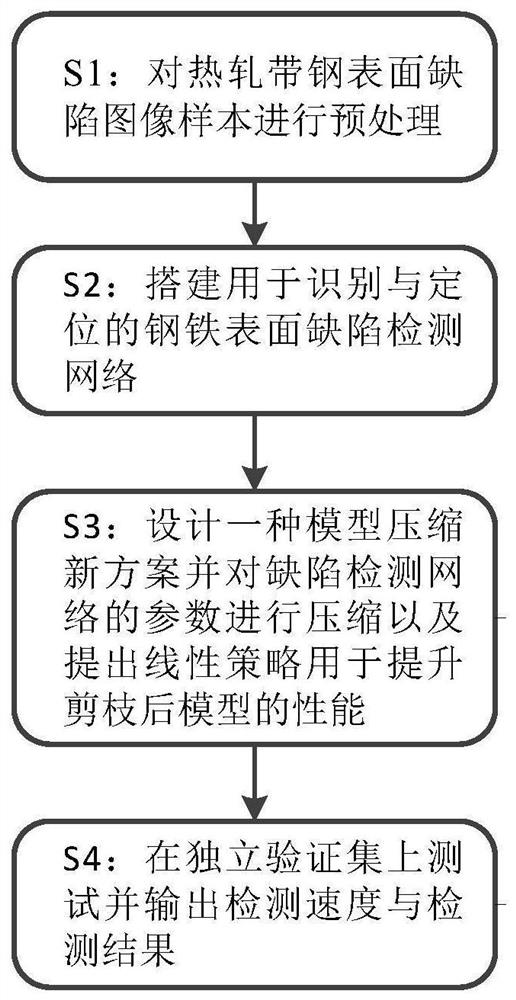

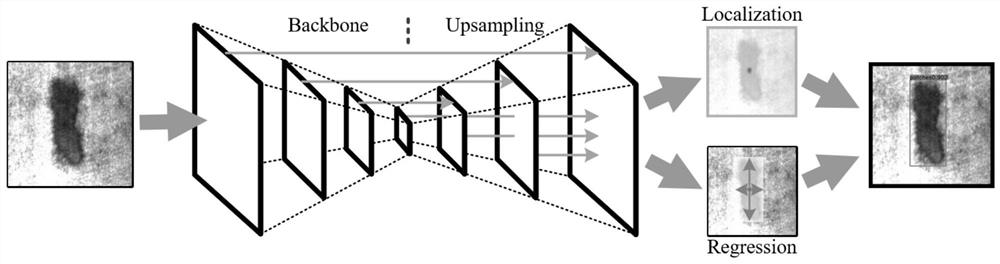

[0049] This embodiment provides a technical solution: a method for detecting surface defects of steel products based on model compression to identify and locate surface defects of hot-rolled strip steel, such as figure 1 As shown, the steps are as follows:

[0050] S1: Preprocessing the image sample of hot-rolled strip surface defects.

[0051] In this step, the following two sub-steps are included:

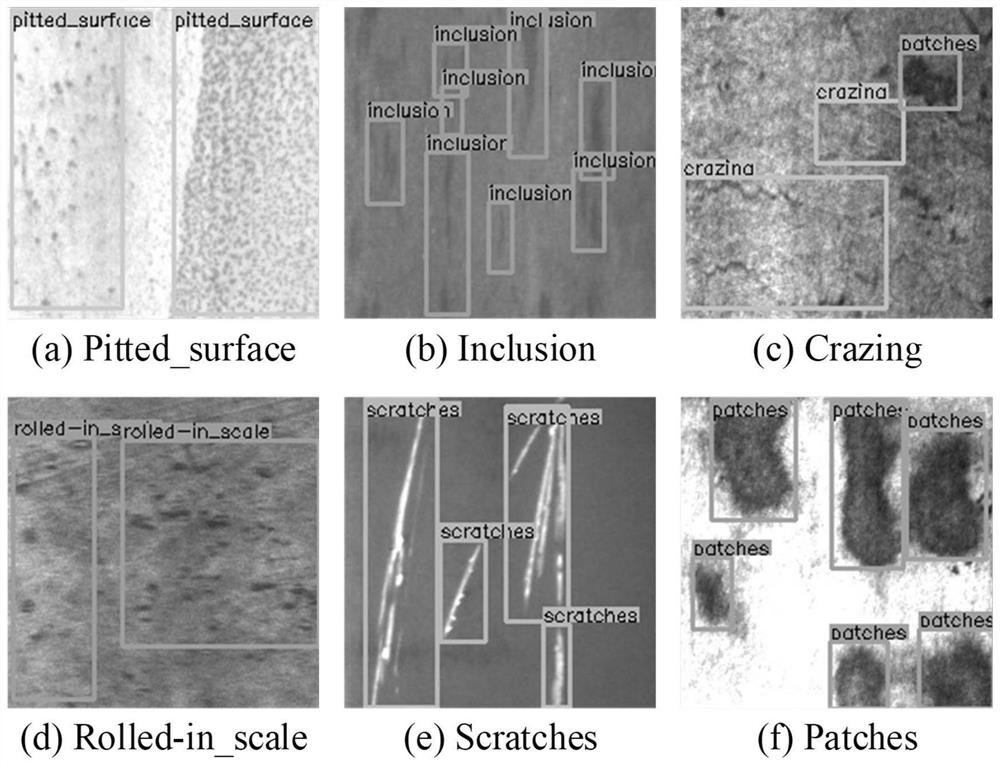

[0052] S11: Obtain the hot-rolled strip surface defect image database on the NEU-DET official website, such as figure 2 As shown, the obtained data samples are divided into a training set and an independent verifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com