Silicon wafer classifying and collecting method

A silicon wafer and chip receiving technology, which is applied to conveyor control devices, conveyor objects, loading/unloading, etc., can solve the problem of low chip receiving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

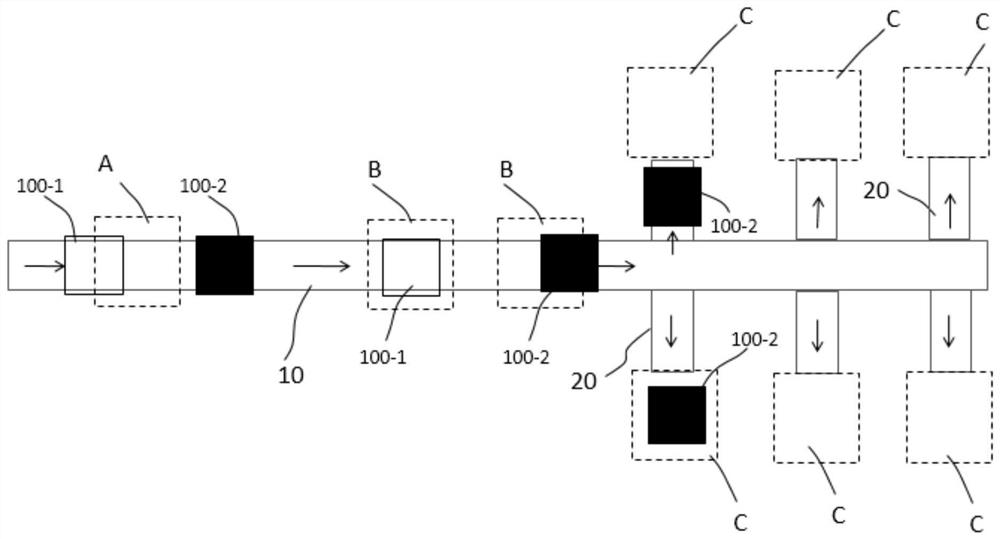

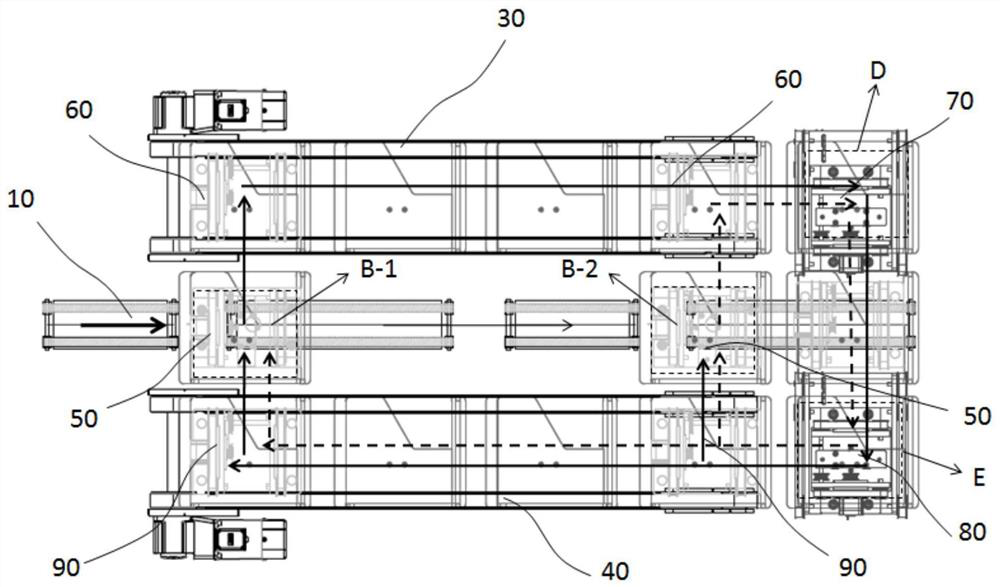

[0056] like figure 2 As shown, in this embodiment, the first type of silicon wafer 100-1 is transported to the first receiving station B by using the first conveying device 10 to implement the receiving of the first type of silicon wafer 100-1, including:

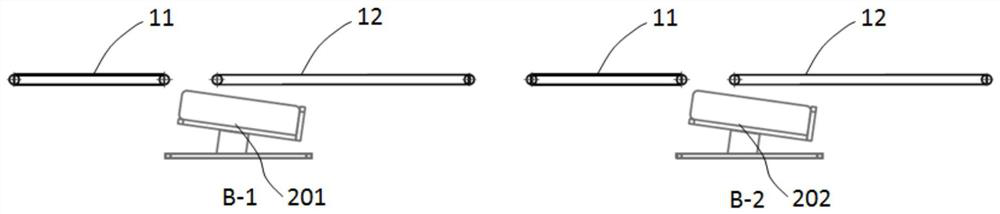

[0057] The first type of silicon wafer 100 - 1 is transported to the magazine located at the first receiving station B by the first transport device 10 . optional, figure 2 In the embodiment, there are two first film receiving stations, respectively the first film receiving station B-1 and the first film receiving station B-2, and the first type of silicon wafer 100-1 is received to In the magazine at the first film receiving station B-1 or the first film receiving station B-2, of course, in other embodiments, one, three, etc. other numbers of first film receiving stations can also be set .

[0058] After the magazine at the first film receiving station B-1 or the first film receiving station B-2 is filled with the fir...

no. 2 approach

[0094] Continuing the description in the first embodiment: after the magazine at the first film receiving station is filled with the first type of silicon wafers 100-1, the full magazine is removed from the first film receiving station and transported to the A receiving station D on the first side of the film receiving station.

[0095] However, when there is currently a stranded full box at the receiving station D, the full box that is currently filled with the first type of silicon wafer 100-1 cannot be directly transported from the first receiving station where it is located to the receiving station. D, thus causing the film to wait.

[0096] In order to solve this problem, a full box buffer station is also provided in this embodiment.

[0097] After the magazine at the first receiving station is full of the first type of silicon wafers 100-1, it is first detected whether there is a magazine at the receiving station D. When there is currently a magazine at the receiving s...

no. 3 approach

[0107] In this embodiment, the silicon wafers of the first type are qualified silicon wafers whose test results meet the predetermined standard, and the silicon wafers of the second type are unqualified silicon wafers whose test results do not meet the predetermined standard. As understood by those skilled in the art, different types of unqualified silicon wafers have different recycling methods. For example, silicon wafers with dirty surfaces may be converted into qualified silicon wafers after cleaning.

[0108] In view of this, according to the test results, the second-type silicon wafers 100-2 are further divided into several sub-categories. For example, the second type of silicon wafer 100-2 is further divided into three subcategories: silicon wafers with dirty surfaces, silicon wafers with holes on the surface, and silicon wafers with chipped edges.

[0109] In this embodiment, the second delivery device 20 transports the second type of silicon wafer 100-2 to the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com