Container type concrete mixing plant

A containerized and containerized technology, applied in mixing plants, clay preparation devices, mixing operation control, etc., can solve the problems of increased foundation construction and treatment costs, unfavorable equipment transfer and transportation, and unsuitable for the development trend of concrete, so as to ensure continuous Sexual and efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

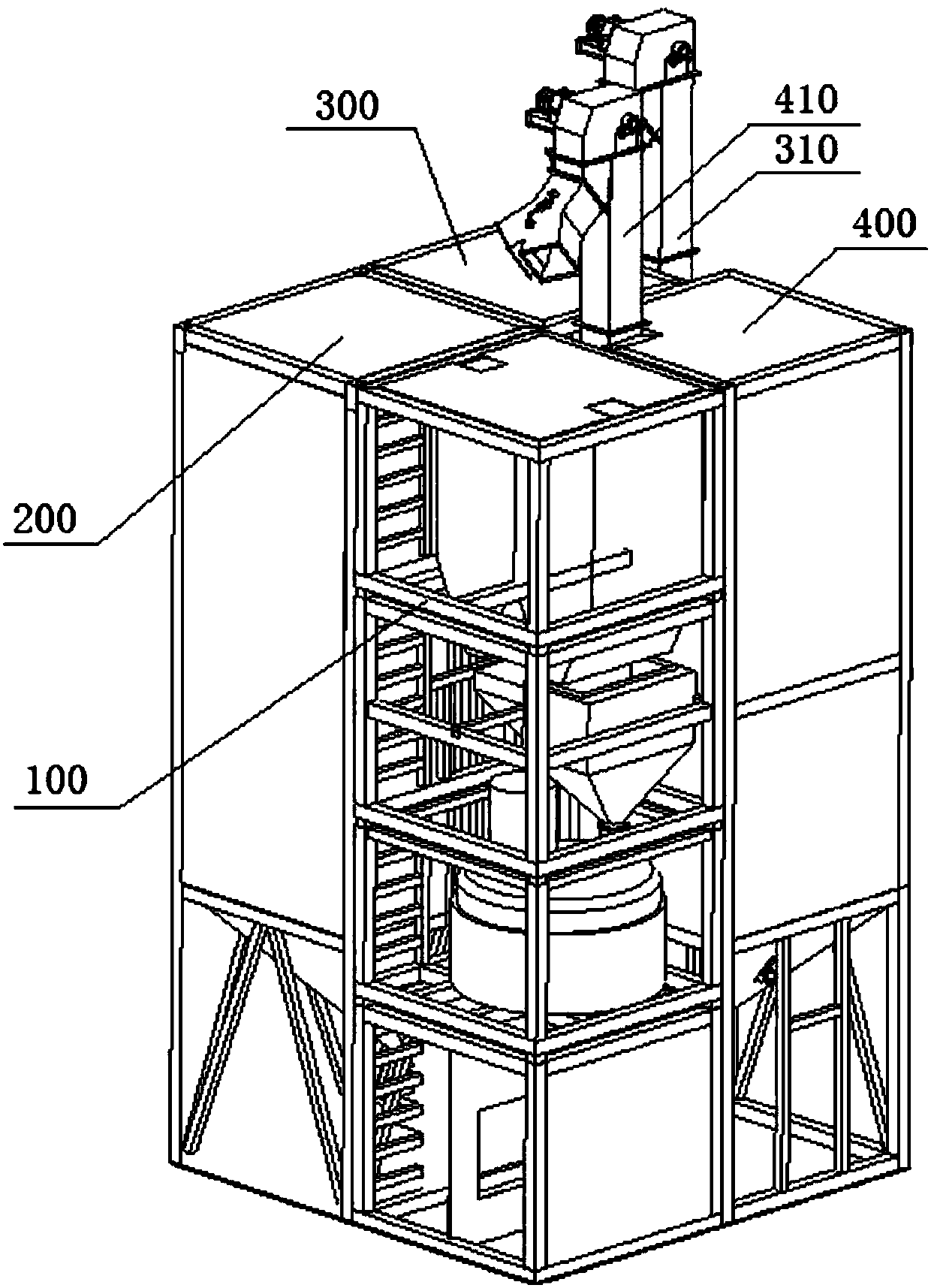

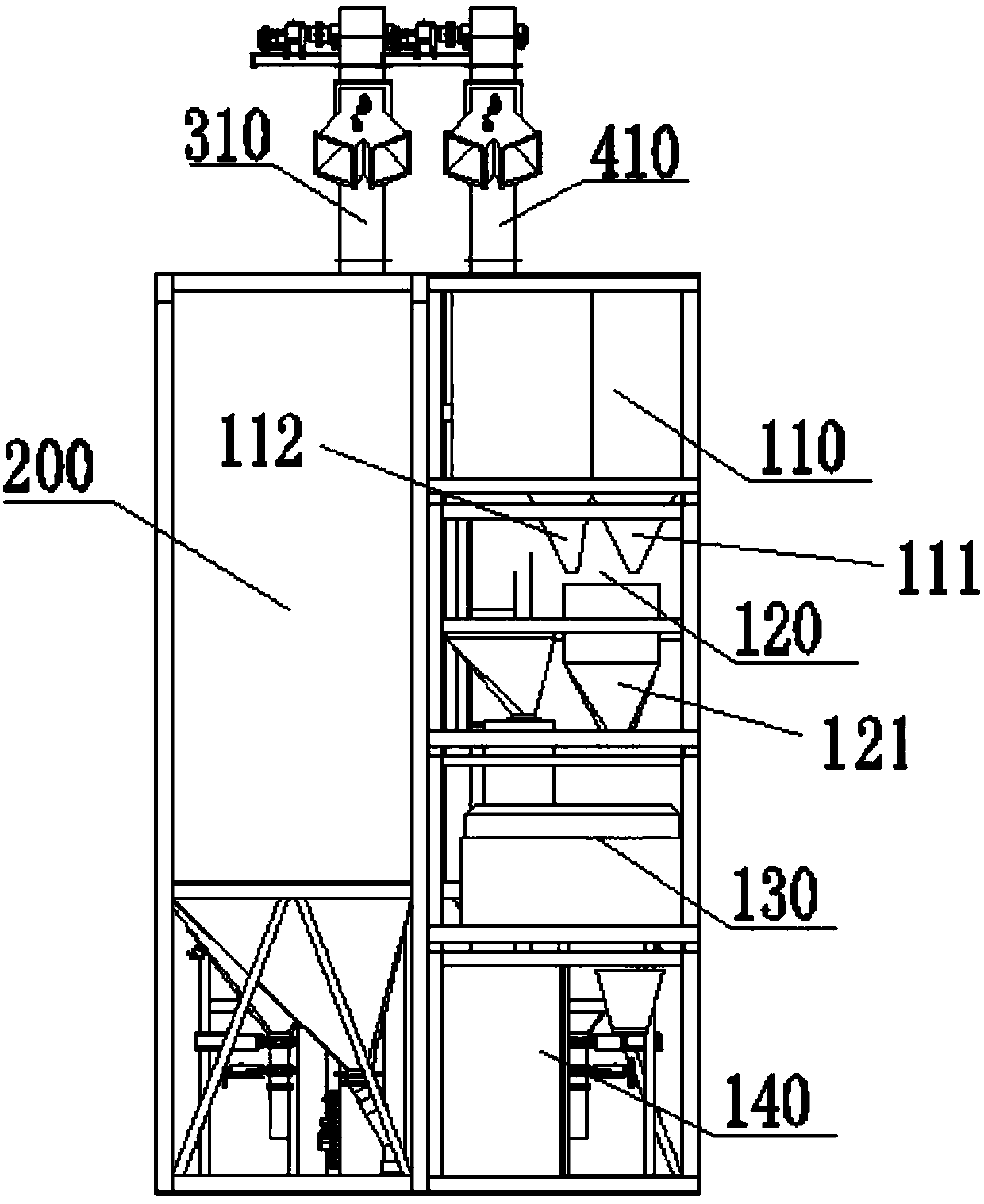

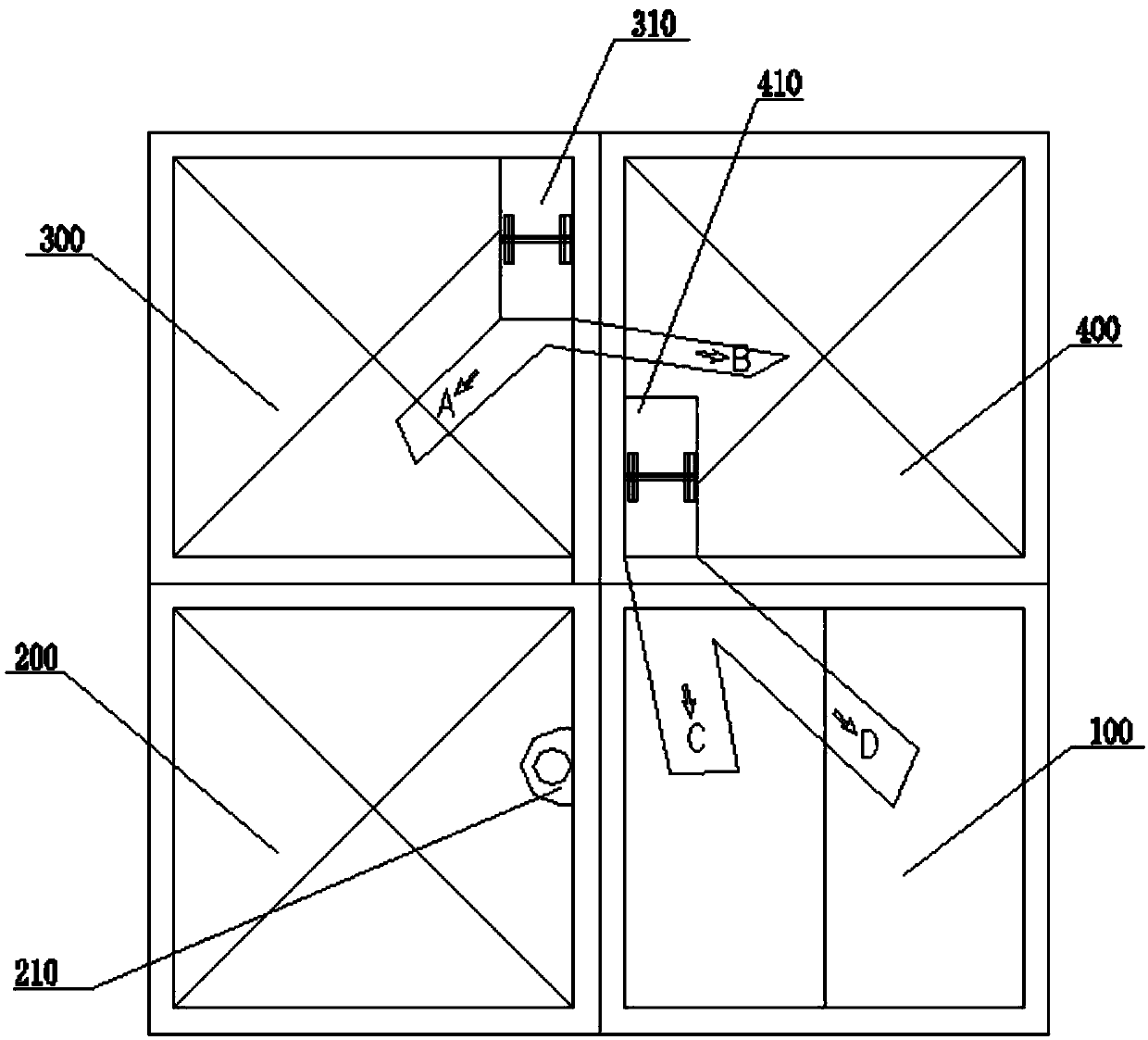

[0030] Such as Figure 1-Figure 3 As shown, this embodiment provides a container-type concrete mixing plant, including a cement storage container 200, an aggregate container, and a main building container 100 for weighing aggregate and cement and making concrete. The fine aggregate container 400 A second bucket elevator 410 for transporting fine aggregate and coarse aggregate to the main building container 100 is provided, and the cement storage container 200 has a screw conveyor 210 for transporting cement to the main building container 100; The material container 200, the aggregate container and the main building container 100 are all modularized and can be assembled temporarily. The feed ports are all connected to the feed end of the container 100 in the main building.

[0031] In this device, the main building container 100, the cement storage container 200, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com