Automatic tower crane clamp switching device and method based on material feature analysis

An automatic switching and clamping technology, which is applied in image analysis, transportation and packaging, load hanging components, etc., can solve the problems of reducing the clamping effect of clamps, and can not take into account the clamping requirements of various types of articulated parts, so as to improve practicality. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to make the purpose, technical solution and advantages of the application more clear, the technical solution in the embodiment of the application will be described in more detail below in conjunction with the drawings in the embodiment of the application.

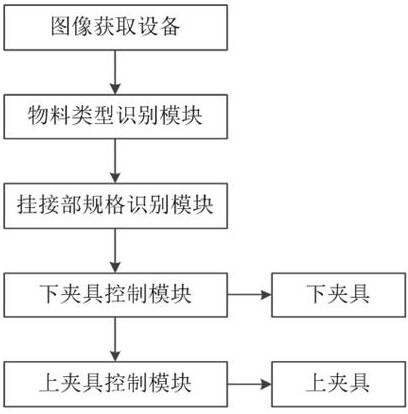

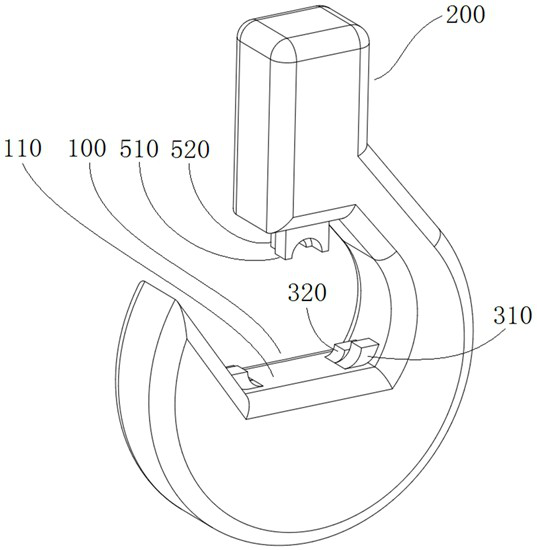

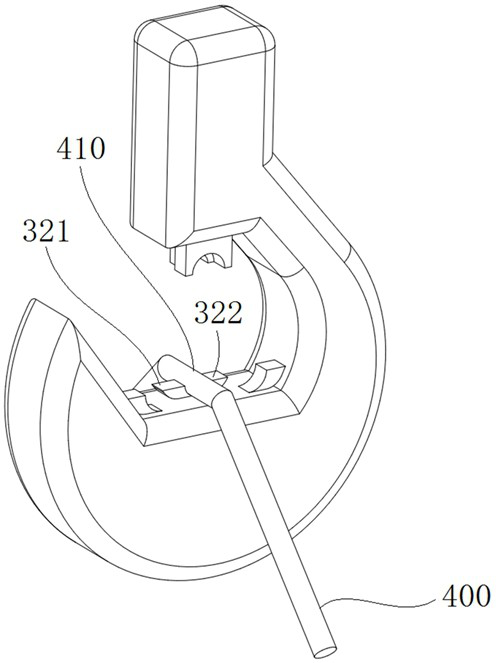

[0077] Refer below Figure 1-Figure 7 The embodiment of the automatic switching device for tower crane clamps based on material characteristic analysis disclosed in this application is described in detail. Such as figure 1 As shown, the clamp automatic switching device disclosed in this embodiment mainly includes an image acquisition device, a material type identification module, a joint specification identification module, a lower clamp control module and an upper clamp control module.

[0078] The image acquisition device is used to acquire the image of the material to be lifted near the hook.

[0079] Assume that there are currently some materials that need to be hoisted, and the materials are bound by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com