A kind of low temperature sintered flexible magnetic sheet and preparation method thereof

A flexible magnetic sheet, low-temperature sintering technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., to solve the adhesion of upper and lower magnetic sheets, improve production efficiency and performance of magnetic sheets, and reduce sintering temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

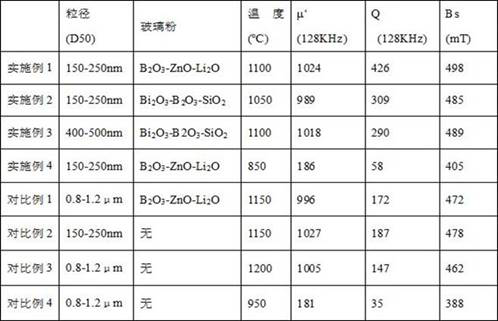

Examples

Embodiment 1

[0026] In this embodiment, a low-temperature sintered flexible magnetic sheet is prepared according to the following method:

[0027] 1) Mixing of raw materials: mix the raw materials in proportion to Fe 2 o 3 : 69.5 wt%, ZnO: 7.00wt% and the balance of MnO are used for batching and sanding, mixed evenly and then dried;

[0028] 2) Pre-burning: Put the dried powder into the firing bowl and put it into the pre-burning furnace and heat it to 850°C at a heating rate of 5°C / min for two hours;

[0029] 3) High-energy ball milling: After vibrating the pre-burned powder, add the auxiliary component CaCO 3 :500ppm, Nb 2 o 5 :200, CuO:1000ppm, Co 2 o 3 : 3000ppm, B 2 o 3 -ZnO-Li 2 O series glass: 1000ppm, then ball milling 2h in a high-energy ball mill to obtain D50 is 150-250nm, and D90 is nano-scale magnetic powder of 250-450nm;

[0030] 4) Pulping: Put the nano-scale magnetic powder prepared in step 3) with xylene, ethanol, and safflower oil in a certain proportion and mix...

Embodiment 2

[0035] In this embodiment, a low-temperature sintered flexible magnetic sheet is prepared according to the following method:

[0036] 1) Mixing of raw materials: mix the raw materials in proportion to Fe 2 o 3 : 69.5 wt%, ZnO: 7.00wt% and the remainder MnO to carry out batching and carry out sanding, dry after mixing evenly;

[0037] 2) Pre-burning: Put the dried powder into the firing bowl and put it into the pre-burning furnace and heat it to 850°C at a heating rate of 5°C / Min for two hours for pre-burning;

[0038] 3) High-energy ball milling: After vibrating the pre-burned powder, add the auxiliary component CaCO 3 :500ppm, Nb 2 o 5 :200, CuO:1000ppm, Co 2 o 3 : 3000ppm, Bi 2 o 3 -B 2 o 3 -SiO 2 System glass: 500ppm, then ball milling 2h in a high-energy ball mill to obtain D50 is 150-250nm, and D90 is nano-scale magnetic powder of 250-450nm;

[0039] 4) Pulping: Put the nano-scale magnetic powder prepared in step 3) with xylene, ethanol, and safflower oil in a c...

Embodiment 3

[0044] In this embodiment, a low-temperature sintered flexible magnetic sheet is prepared according to the following method:

[0045] 1) Mixing of raw materials: mix the raw materials in proportion to Fe 2 o 3 : 69.5 wt%, ZnO: 7.00wt% and the remainder MnO to carry out batching and carry out sanding, dry after mixing evenly;

[0046] 2) Pre-burning: Put the dried powder into the firing bowl and put it into the pre-burning furnace and heat it to 850°C at a heating rate of 5°C / Min for two hours for pre-burning;

[0047] 3) High-energy ball milling: After vibrating the pre-burned powder, add the auxiliary component CaCO 3 :500ppm, Nb 2 o 5 :200, CuO:1000ppm, Co 2 o 3 : 3000ppm, Bi 2 o 3 -B 2 o 3 -SiO 2 System glass: 500ppm, then obtain D50 and be 400-500nm by ball milling 1h in high-energy ball mill, D90 is the nanoscale magnetic powder of 500-700nm;

[0048] 4) Pulping: Put the nano-scale magnetic powder prepared in step 3) with xylene, ethanol, and safflower oil in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com