Preparation method of oxidation-resistant non-discoloring composite reverse-osmosis membrane

A reverse osmosis membrane and anti-oxidation technology, applied in the field of membrane separation, can solve the problems of discoloration and yellowing of the membrane, and achieve the effect of solving discoloration and yellowing, performance improvement and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

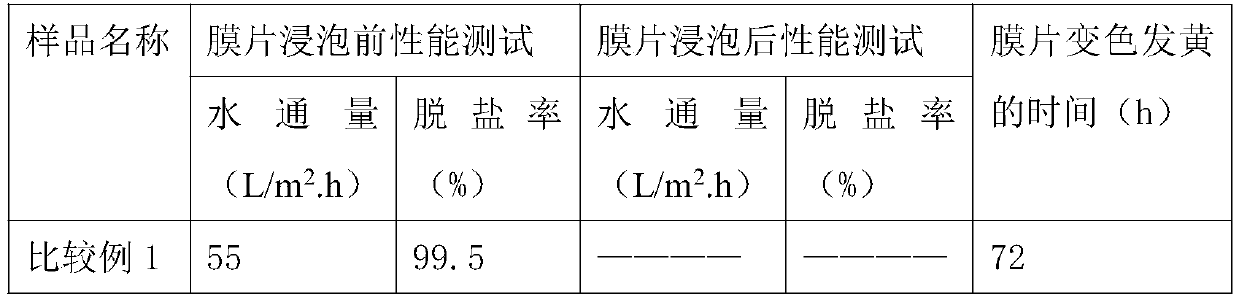

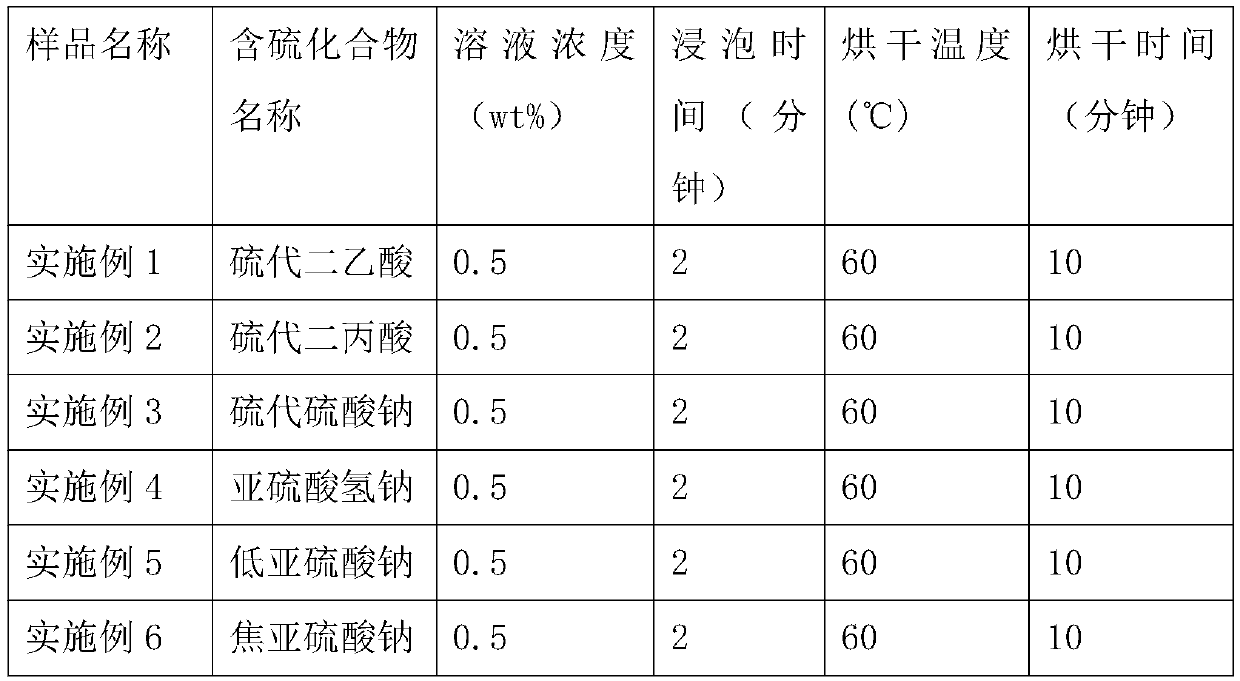

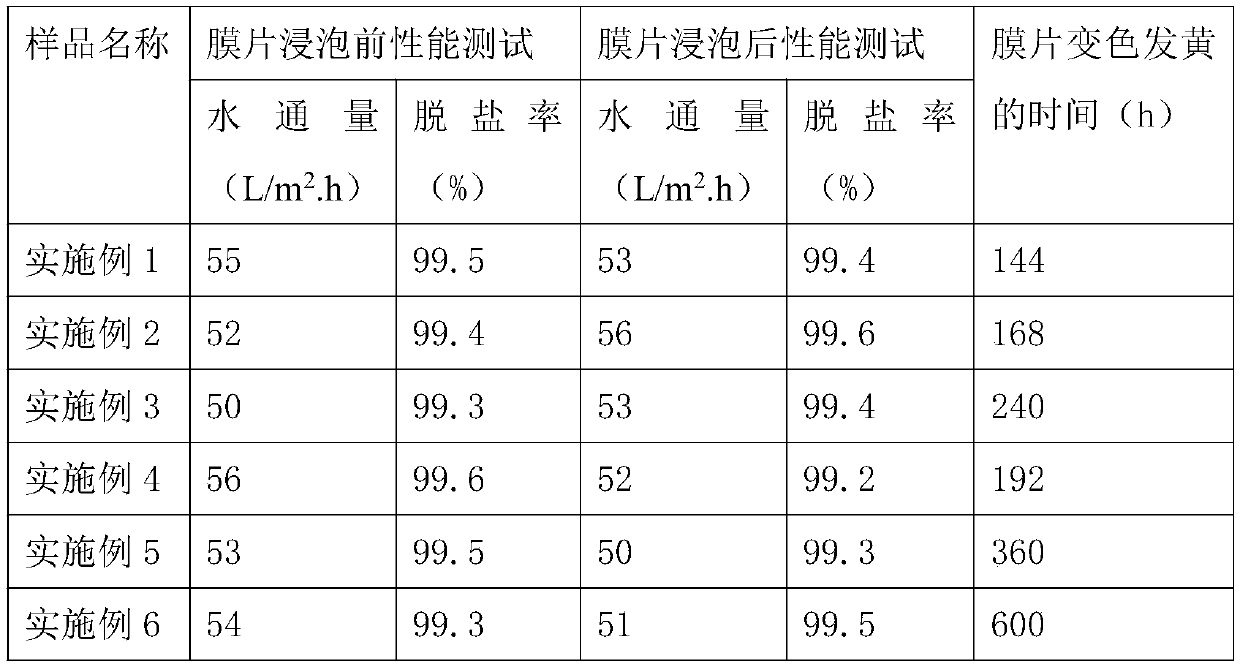

Examples

preparation example Construction

[0018] The preparation method of composite reverse osmosis membrane in the application:

[0019] First, m-phenylenediamine (MPD), camphorsulfonic acid (CSA) and sodium dodecylsulfonate (SDS) were added into pure water, and the pH was adjusted with triethylamine (TEA) to prepare an aqueous phase solution; Trimellitic chloride (TMC) was dissolved in isoparaffin (Isopar G) to prepare an organic phase solution. Immerse the polysulfone support membrane (molecular mass cut-off of about 20k) in the aqueous phase solution for 60s, remove the excess aqueous phase solution on the surface after taking it out, then react in the organic phase solution for 30s, and then heat-treat it in an oven at 100°C for 6min to prepare A composite reverse osmosis membrane is obtained.

[0020] The treatment method of anti-oxidation and non-discoloration of composite film:

[0021] Soak the composite reverse osmosis membrane in a sulfur-containing compound solution with a mass concentration of 0.2-5wt%...

Embodiment 7-12

[0033]

[0034] Carry out diaphragm separation test and anti-oxidative discoloration experiment with the diaphragm of embodiment column 7-12

[0035]

[0036] The above examples show that the composite reverse osmosis membrane is soaked in a sulfide-containing solution, and the solution concentration needs to be controlled at 0.2-5.0wt%.

Embodiment 13-18

[0038]

[0039] Carry out diaphragm separation test and anti-oxidative discoloration experiment with the diaphragm of embodiment column 13-18

[0040]

[0041] The above implementation list shows that the composite reverse osmosis membrane is soaked in a sulfide-containing solution, the soaking time of the solution needs to be controlled at 2-5 minutes, the drying temperature is 50-80°C, and the drying time is 5-10 minutes. The salt rejection rate remains basically unchanged, while the ability to resist oxidation and discoloration has been greatly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com