Glass lining equipment

A glass-lined and equipment technology, applied in the field of glass equipment, can solve problems such as damage to equipment connections, inability to open safety valves, and impact at equipment connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

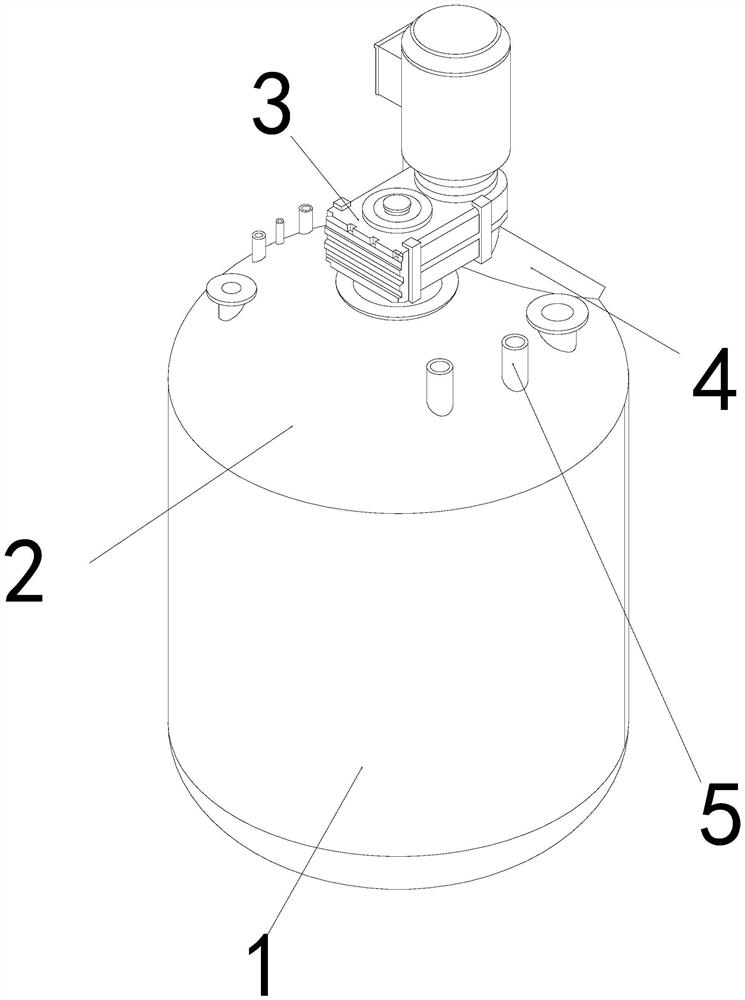

[0025] as attached figure 1 to attach Figure 5 As shown, the present invention provides a glass-lined equipment, the structure of which includes a cylinder body 1, a top cover 2, a safety valve 3, a filling hole 4, and a pressurizing tube 5, and the outer wall of the lower end of the top cover 2 is snapped The outer wall of the lower end of the safety valve 3 is nested and fixed on the inner wall of the center of the top cover 2, the lower end of the injection hole 4 is welded and fixed on the upper end of the top cover 2, and the lower end of the pressure tube 5 is embedded and fixed. fixed on the upper surface of the top cover 2;

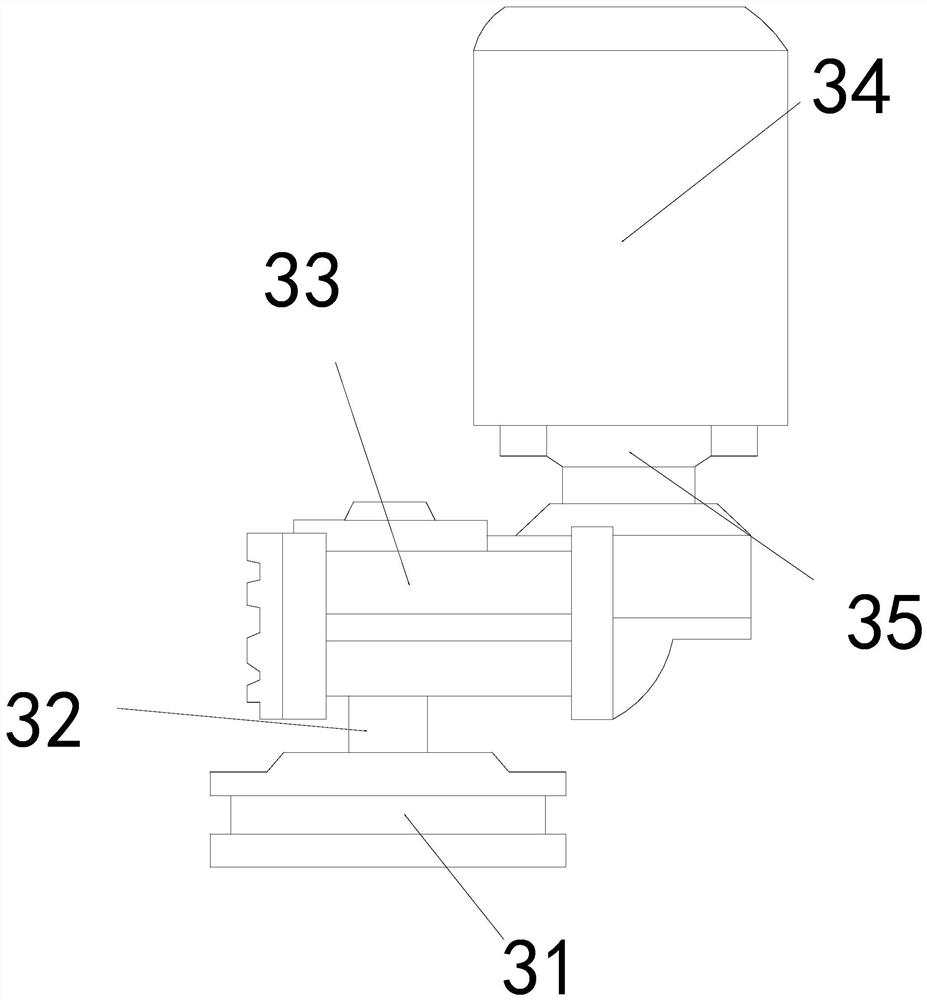

[0026] The safety valve 3 is composed of a fixed seat 31, an exhaust rod 32, a main body 33, a driver 34, and an assembly seat 35. The sleeve is assembled on the inner wall of the main body 33, the upper end on the right side of the main body 33 is welded and fixed to the lower end of the assembly seat 35, the lower end of the driver 34 is fixe...

Embodiment 2

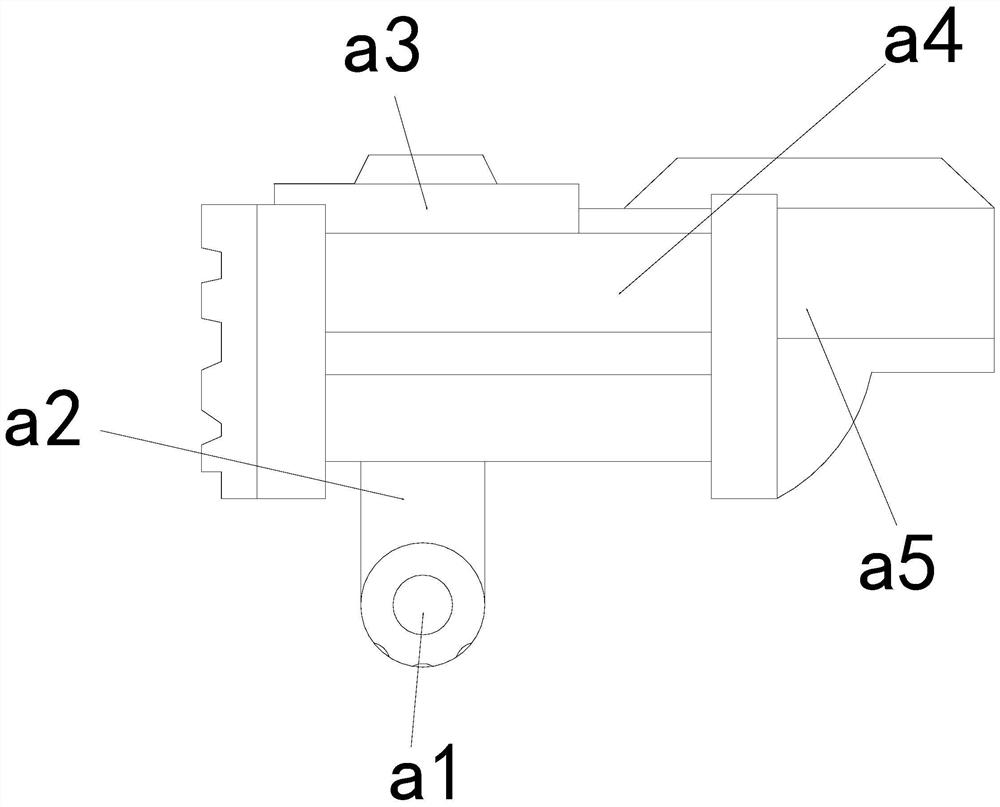

[0032] as attached Figure 4As shown: the rectification mechanism a1 is composed of an air inlet b1, a ring body b2, a push block b3, a rectification ring b4, and a blade b5. The outer wall of the middle section of the block b3 is gap-fitted with the inner wall of the upper end of the ring body b2, the outer wall of the rectifying ring b4 is nested and fitted on the inner wall of the ring body b2, the lower end of the blade b5 is welded and fixed to the outer wall of the rectifying ring b4, and the upper end of the push block b3 is connected to the movable seat There is a movable fit at the lower end of d1, and there are five blades b5 in total. The structure is an inclined structure, arranged circularly on the outer wall of the rectifying ring b4, guided by the angle of the structure, so that the high-pressure airflow entering the ring b2 can drive the blades b5 to rotate.

[0033] as attached Image 6 to attach Figure 7 As shown: the pressure relief valve a3 is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com