Button type supercapacitor negative electrode cover tray

A technology of supercapacitors and negative electrode caps, applied in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of high equipment cost, increased procurement cost, energy consumption cost, large production space, etc., to reduce production cost, improve material transfer efficiency, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

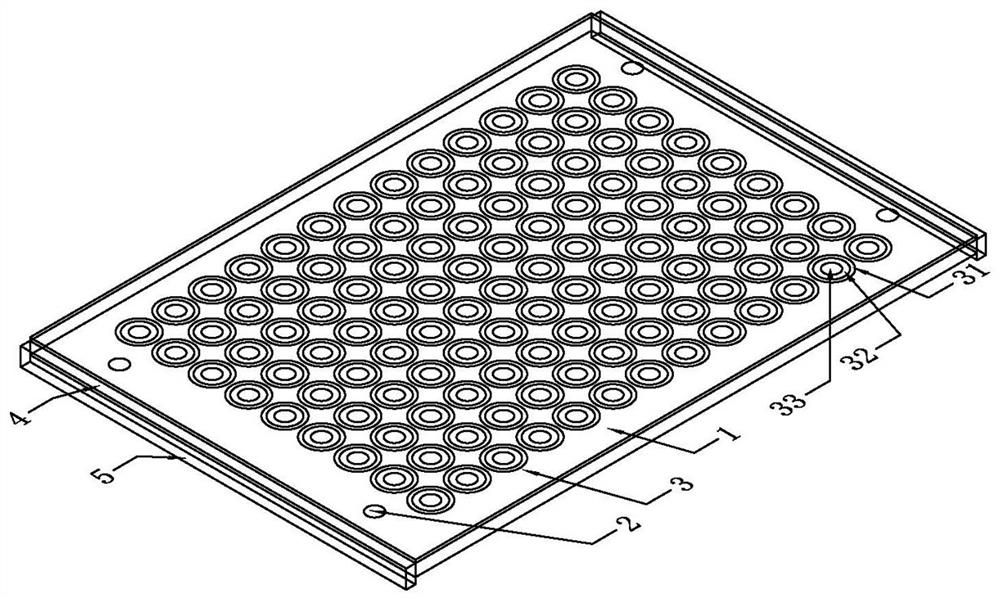

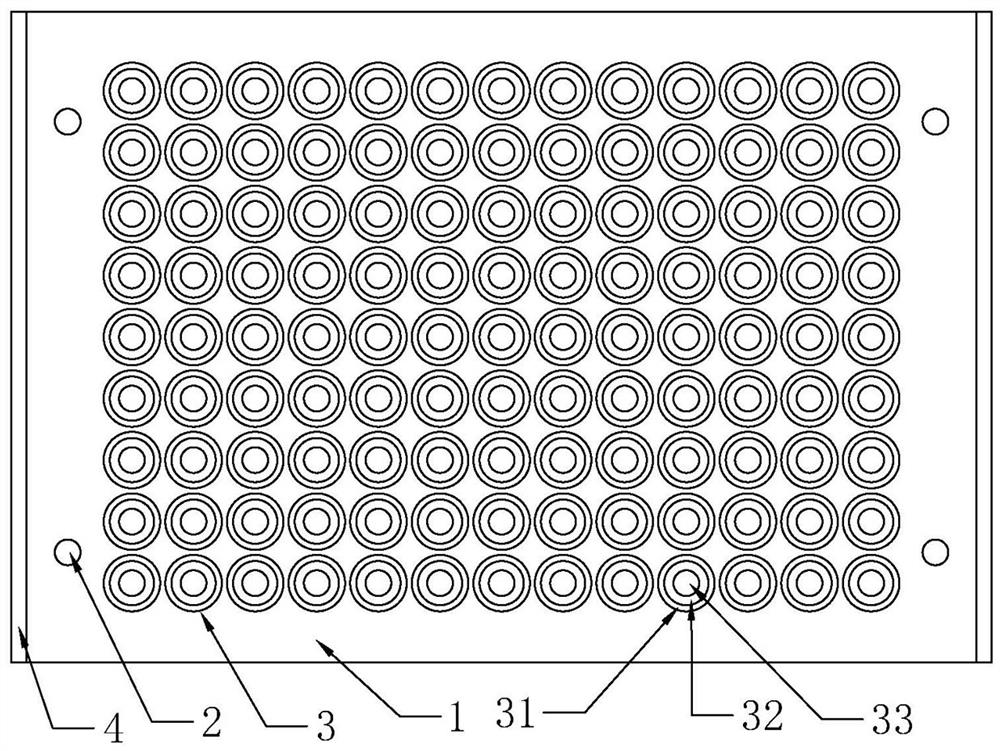

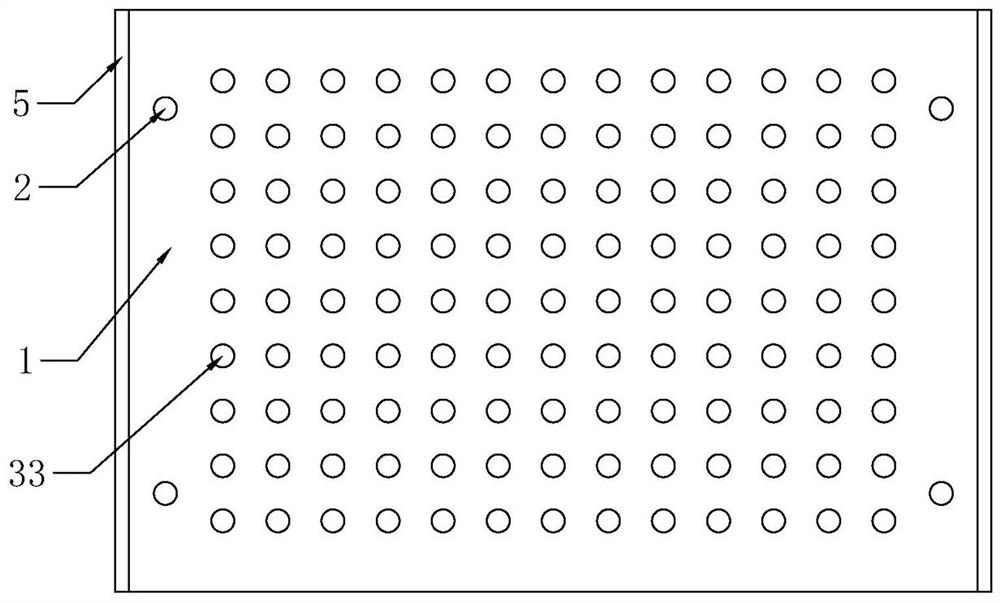

[0023] Such as Figure 1 to Figure 6 As shown, a button-type supercapacitor negative electrode cover tray includes a tray body (1) and a positioning hole (2). Covers (3) are closely arranged on the disc body, and the cover (3) includes a shoulder support (31), a bottom support (32) concentric with the shoulder support (31), and a bottom support (32) concentric with the bottom support (32). Mounting holes (33). The disk body (1) has disk shoulders (4) and disk feet (5) on both sides in the length direction.

[0024] The tray body (1) is made of plastic or metal. Since the pole piece drying process requires the tray and the negative electrode piece to be baked in a vacuum oven, it is required that the tray can withstand baking at a temperature above 100°C for a long time without deformation.

[0025] Combined with the structural characteristics of the human palm, the length and width of the tray body should be designed so that workers can hold the tray repeatedly and firmly wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com