A stator slot wedge and a wet stator submersible motor using the stator slot wedge

A stator slot and stator core technology, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of unit failure and easy damage to the insulation of the stator coil 60, and achieve the effect of prolonging the service life, convenient installation and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the purpose and advantages of the present application clearer, the present application will be specifically described below in conjunction with the embodiments. It should be understood that the following words are only used to describe one or several specific implementation modes of the application, and do not strictly limit the scope of protection specifically requested by the application. The features in the examples can be combined with each other.

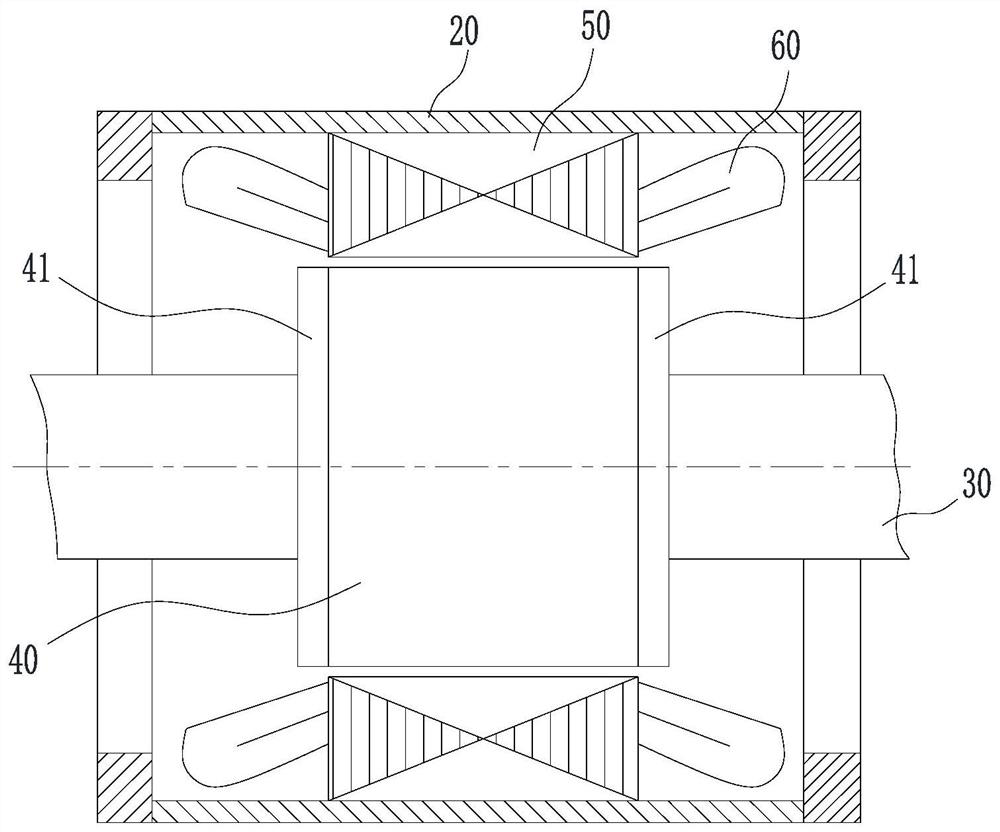

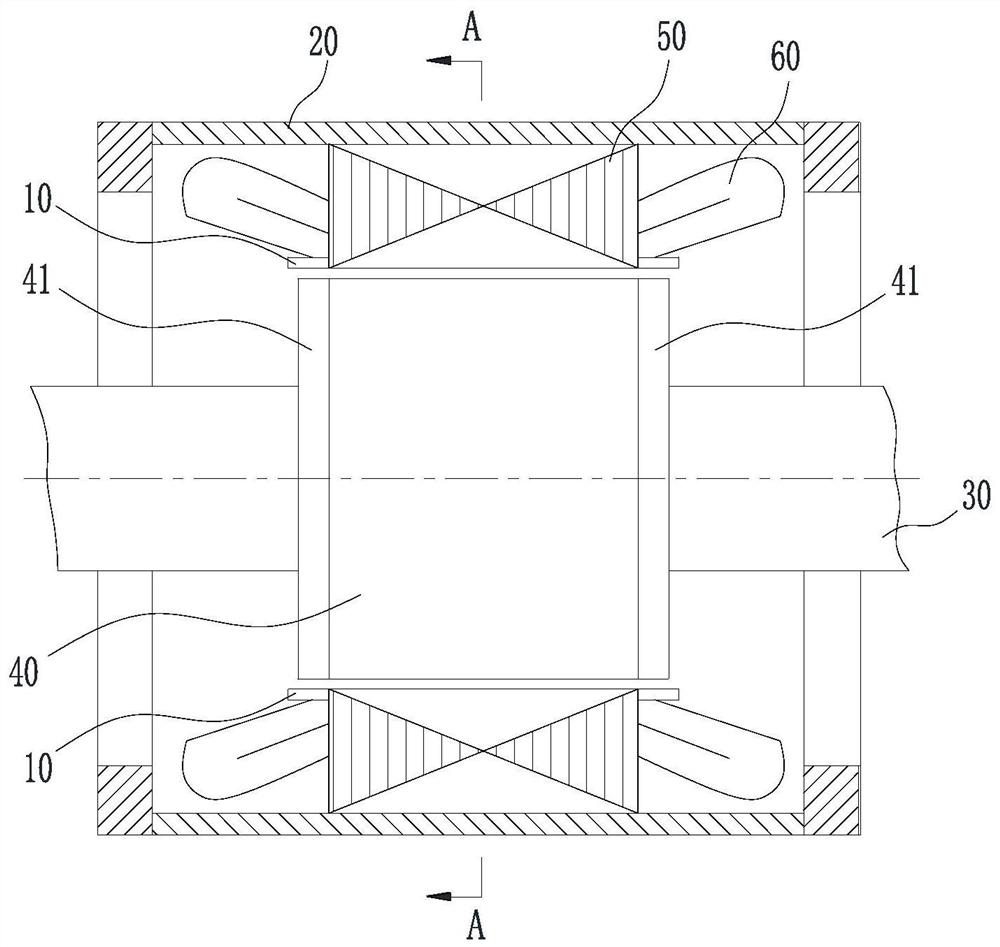

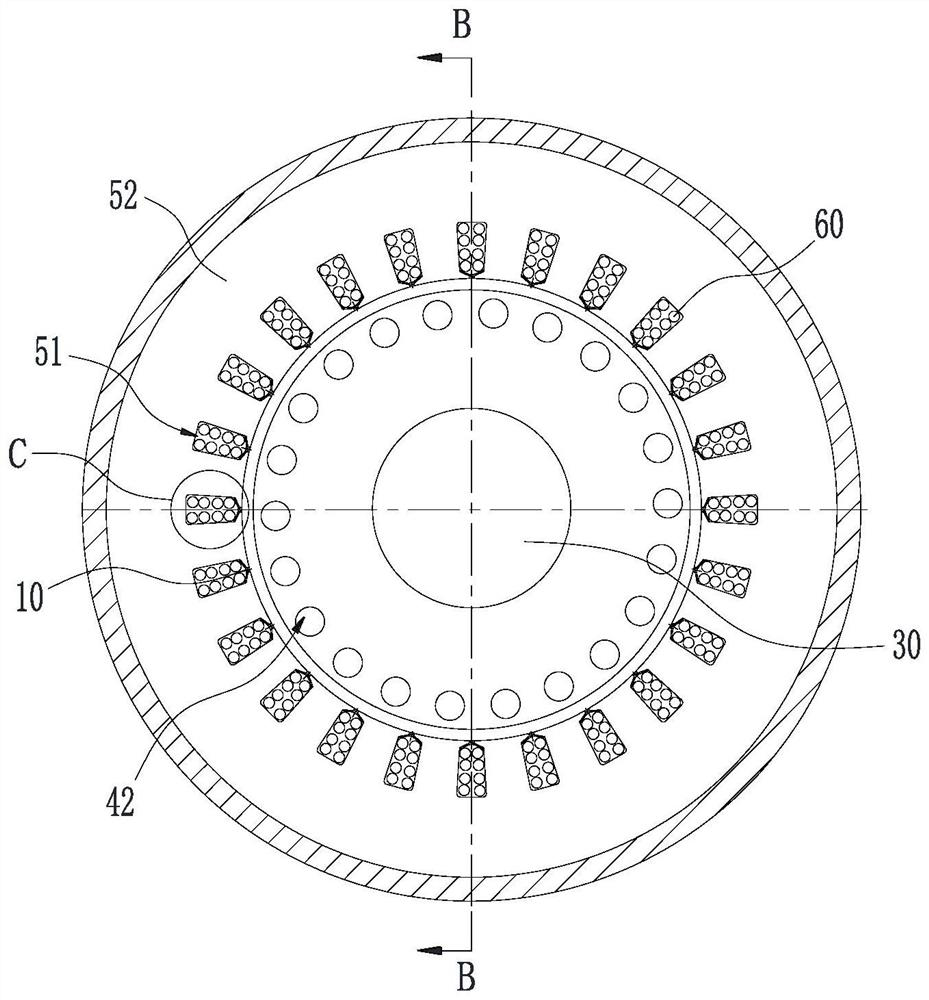

[0050] refer to figure 1 , in the existing wet stator submersible motor, the rotor end rings 41 are welded to the two ends of the cylinder of the rotor core 40, sleeved in the inner cavity of the stator, and located at the part where the stator coil 60 protrudes from the stator core 50 to form inside the ring cavity. When the motor rotates, the rotation of the rotor drives the water in the chamber to rotate, and the water flow will be subjected to centrifugal force during the rotation. And because the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com