Patents

Literature

53results about How to "Accurate snap connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

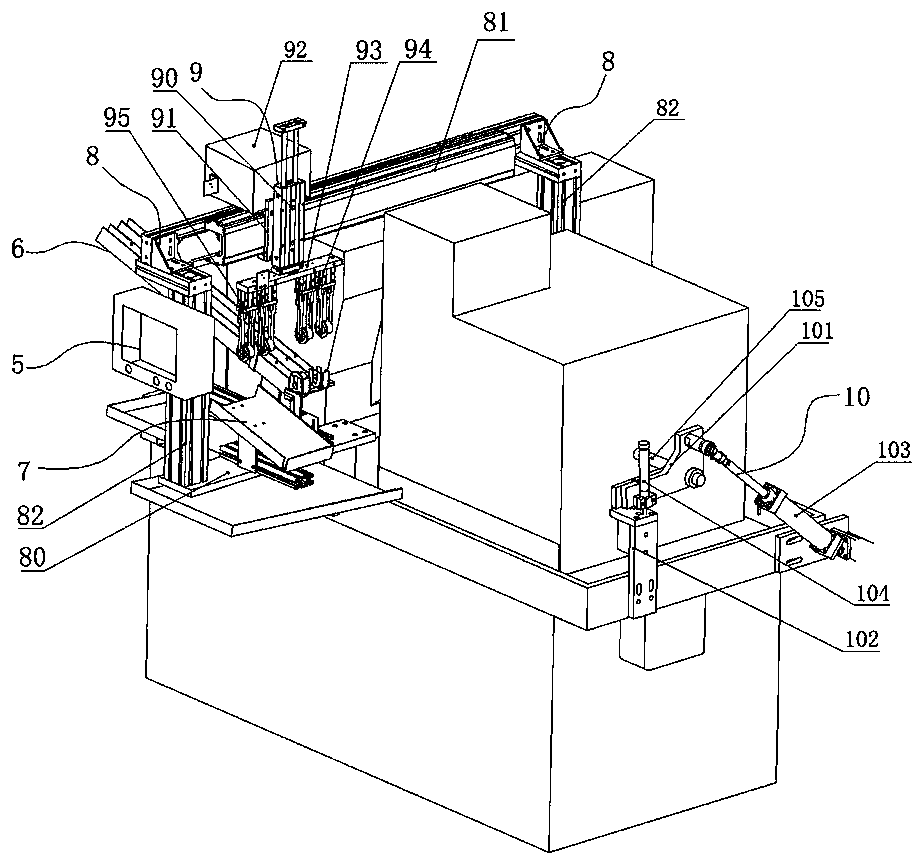

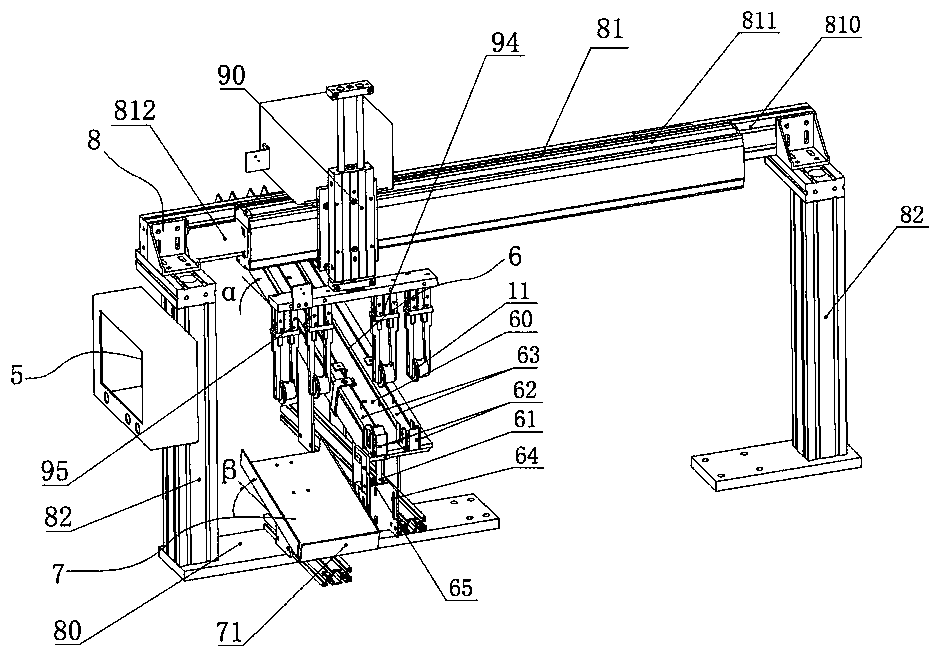

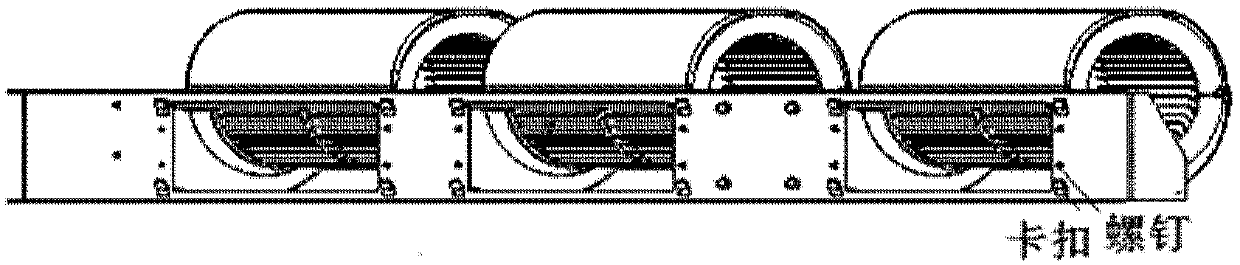

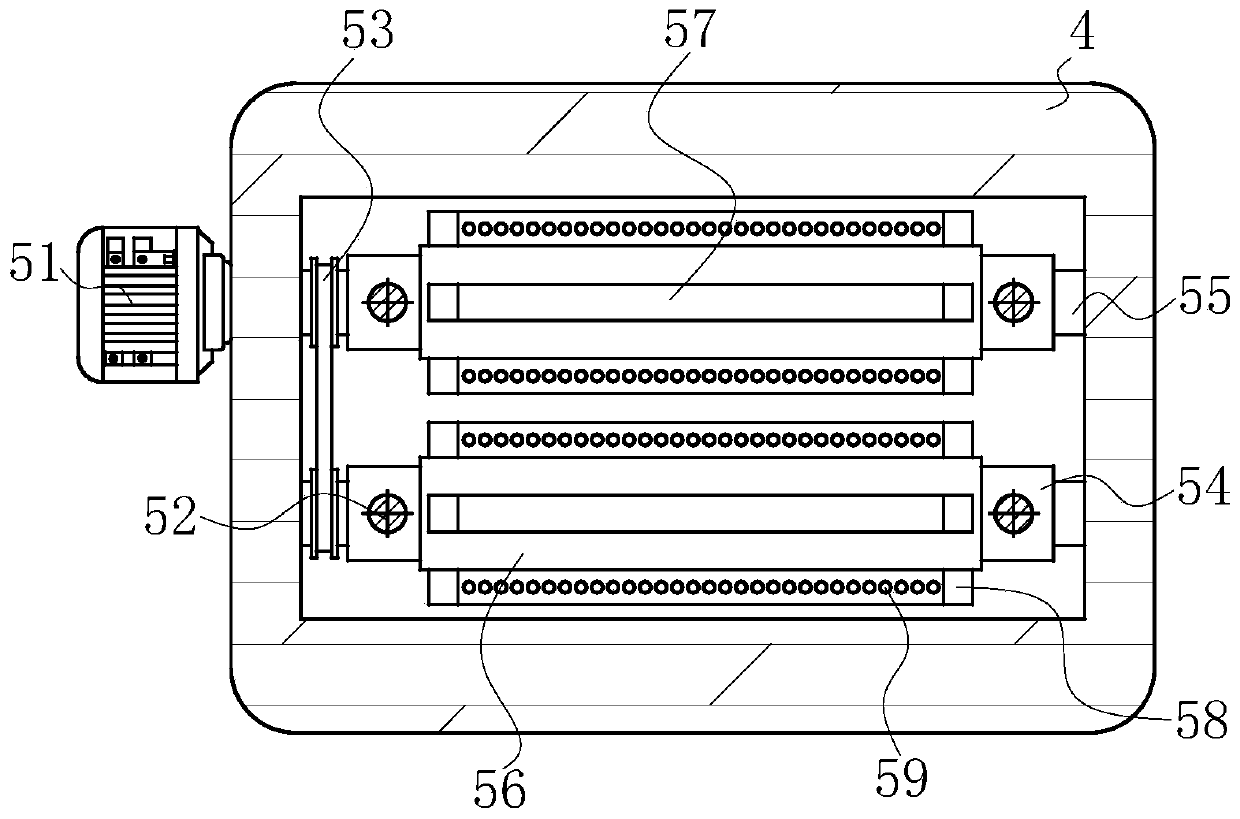

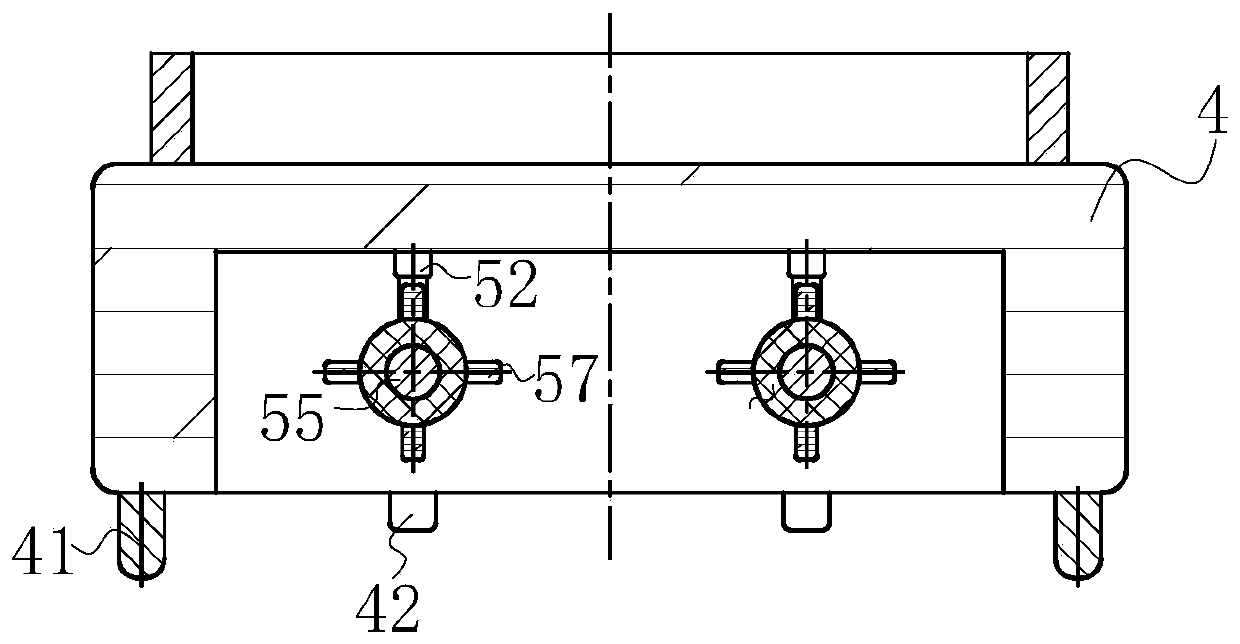

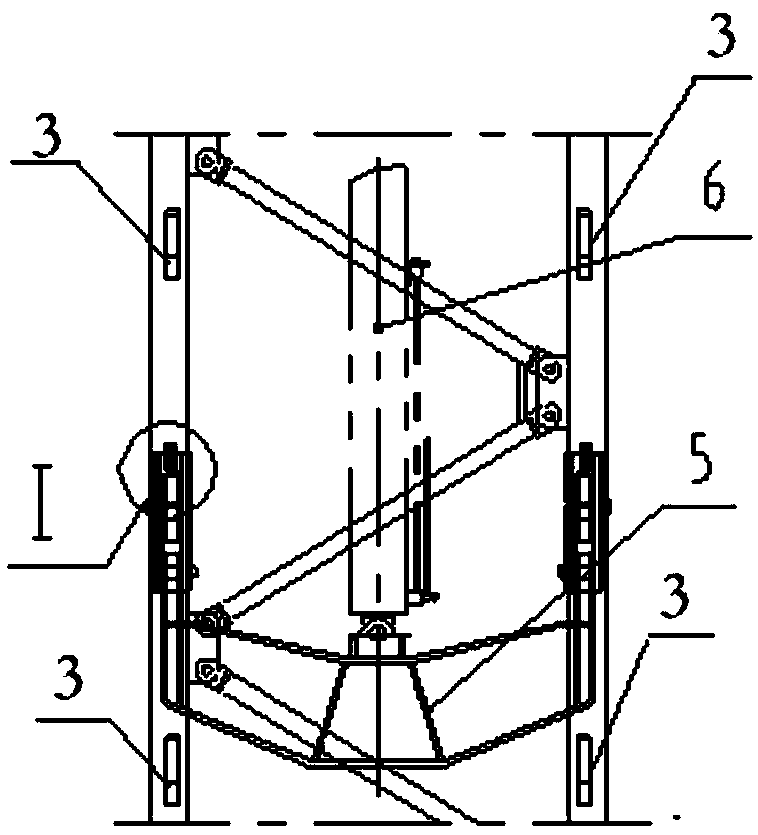

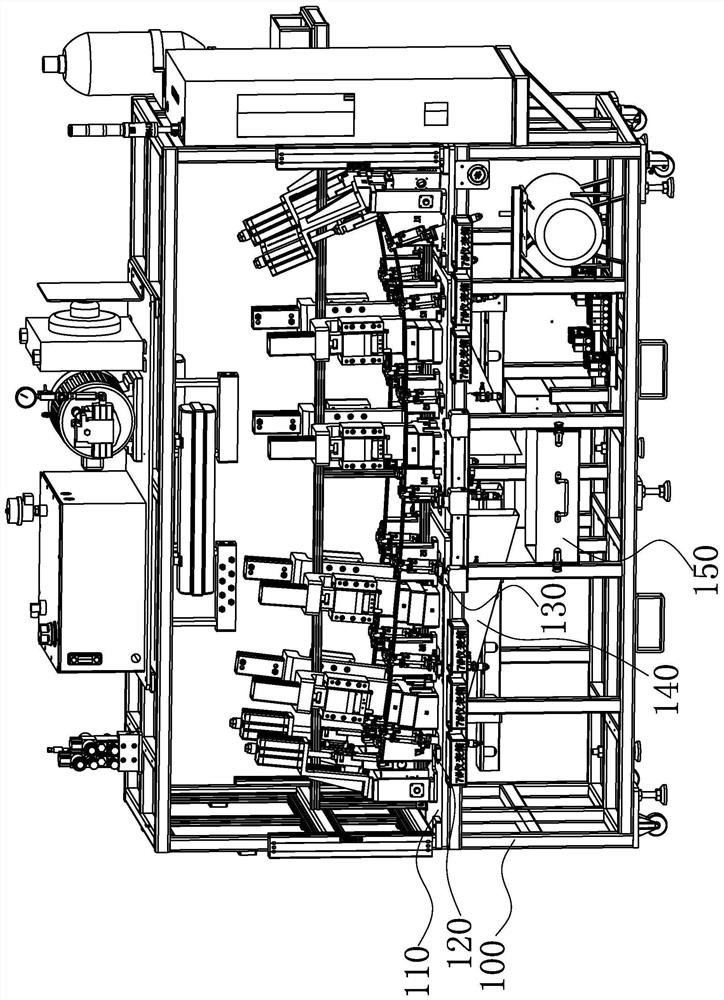

Machining process of loading and unloading conveying device and step shaft sleeves of centerless grinding machine

ActiveCN108436627ASwing neatlyGuarantee processing qualityRevolution surface grinding machinesEngineeringMachining process

The invention relates to the field of machining of centerless grinding machines, in particular to a machining process of a loading and unloading conveying device and step shaft sleeves of a centerlessgrinding machine. The centerless grinding machine comprises a grinding machine base, a grinding wheel, an adjusting wheel and a workpiece bracket; the loading and unloading conveying device comprisesa control cabinet, a feeding mechanism, a discharge bin, a loading and unloading conveying mechanism, a loading and unloading clamping mechanism and a pushing device; the control cabinet is electrically connected with the feeding mechanism, the loading and unloading conveying mechanism and the loading and unloading clamping mechanism; the feeding mechanism takes the charge of tidily placing the step shaft sleeves in sequence; the loading and unloading conveying device is an operating procedure of supporting the loading and unloading clamping mechanism, so that the step shaft sleeves are smoothly loaded and unloaded on the grinding machine, and the manual loading time is saved; through cooperation of the pushing device and the discharge bin, full-automatic grinding is realized, so that thelabor intensity of operators is effectively reduced; and a loading clamping hand and an unloading clamping hand can once clamp at least two step shaft sleeves, so that one half of the machining timeis saved, the labor productivity is improved, and the batch production is achieved.

Owner:CHONGQING ELECTROMECHANICAL VOCATIONAL INST

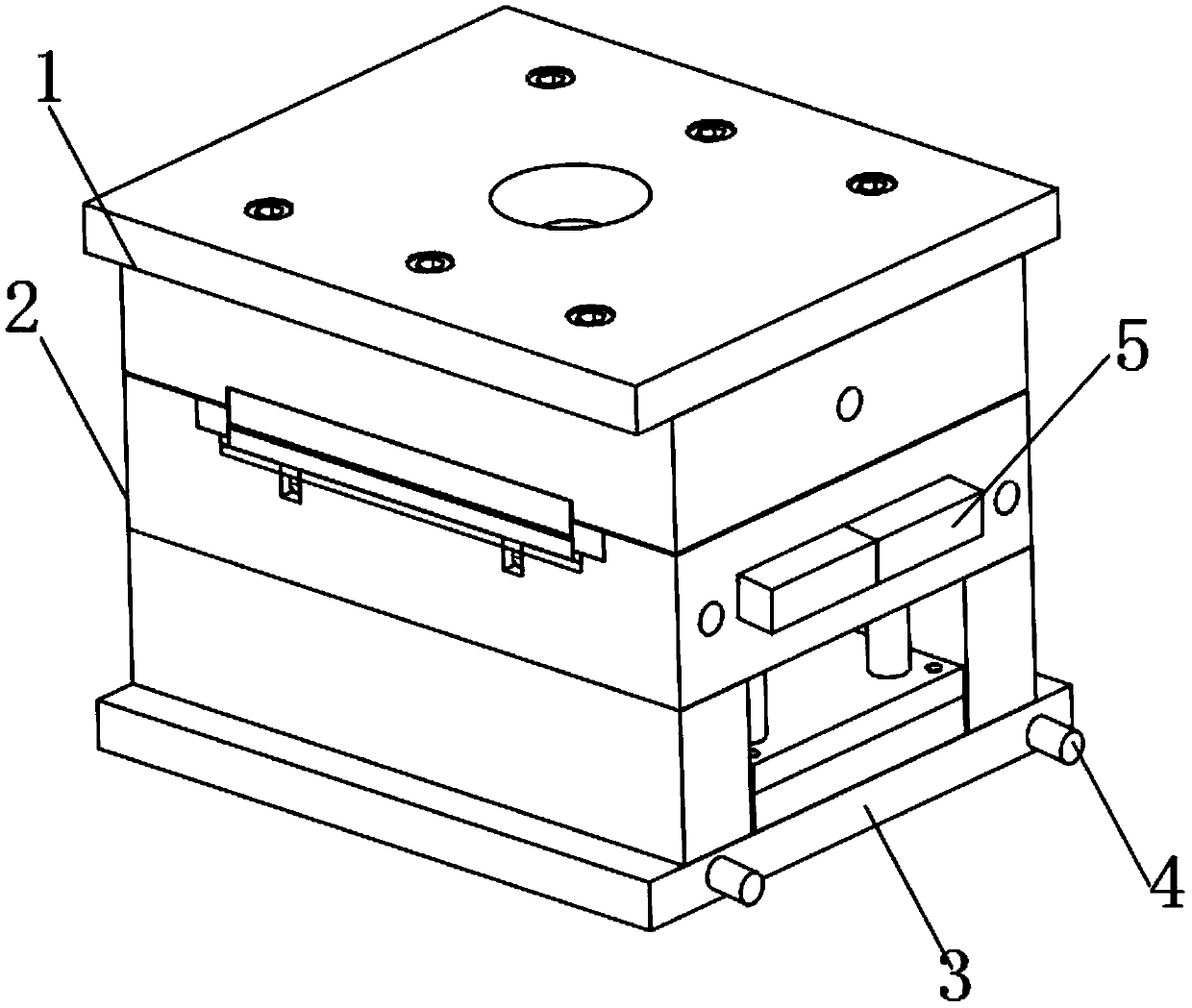

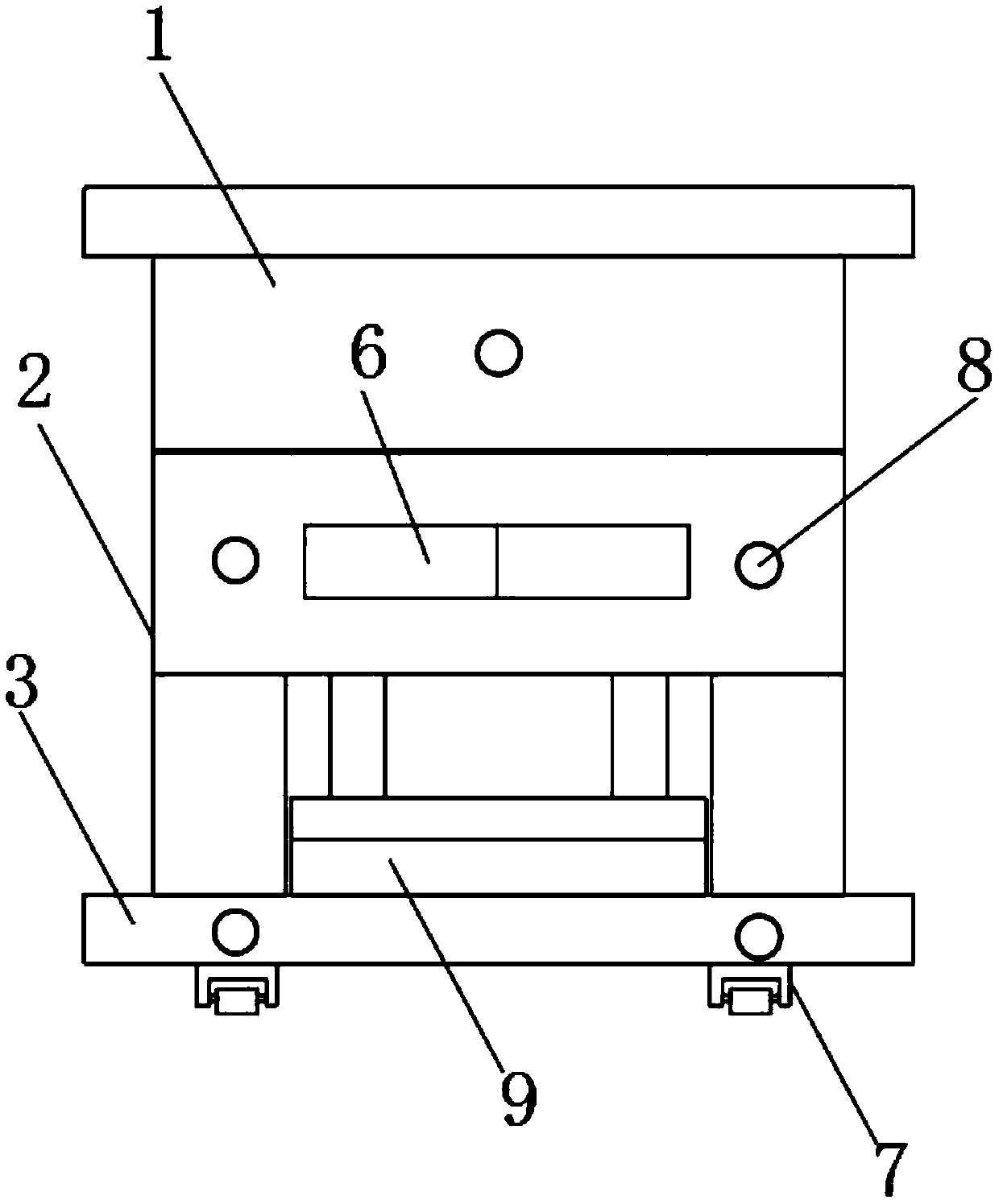

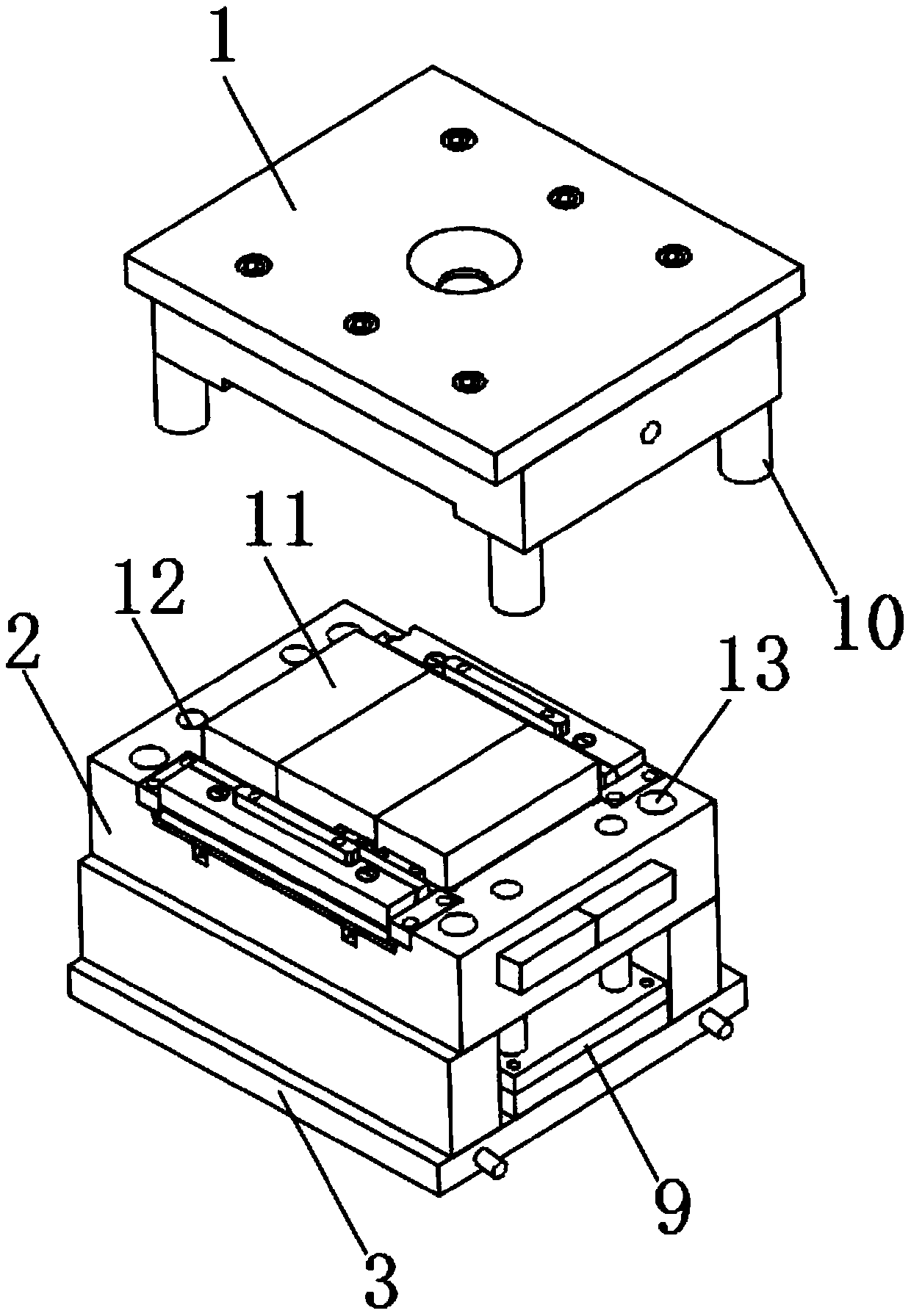

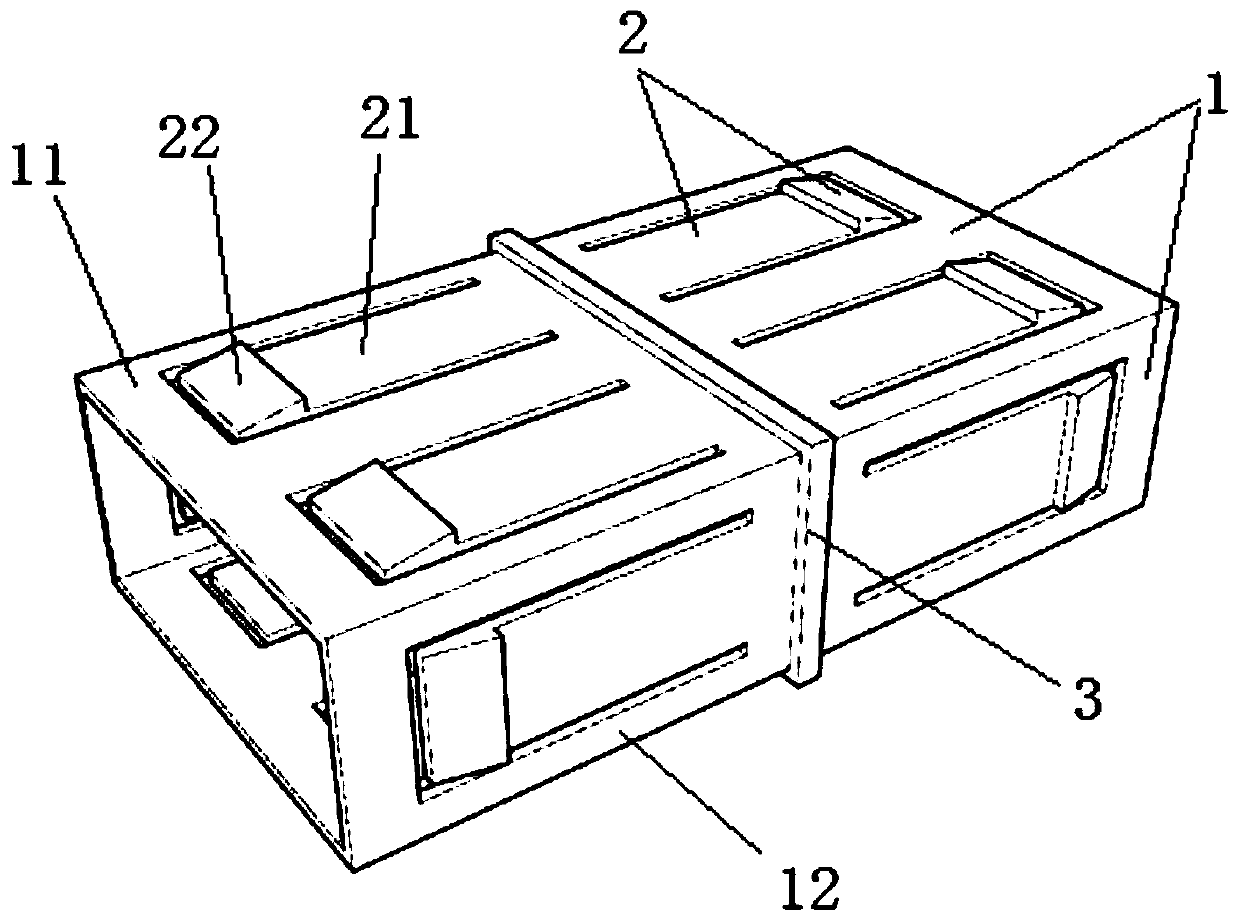

Injection mold with high adjusting precision and convenience in disassembling and assembling and using method of injection mold

The invention discloses an injection mold with high adjusting precision and convenience in disassembling and assembling and a using method of the injection mold. The injection mold comprises an upper mold and a lower mold. Chutes are separately formed in the two sides of the middle of the bottom of the upper mold and the two sides of the middle of the top of the lower mold; an upper mold core and a lower mold core are separately installed on the middle of the bottom of the upper mold and the middle of the top of the lower mold in a clamping manner; each of the upper mold core and the lower mold core consists of a plurality of module boards; and side plates are mounted at the ends of the upper mold and the lower mold and are separately positioned on the two sides of the upper mold core and the two sides of the lower mold core. Owing to the modular design of the mold cores, the mold cores are refined, after a part of one of the mold cores is damaged, part of the modular boards can be changed, the whole mold cores do not need to be changed, the injection mold is simple to maintain, and the maintenance cost is reduced. When the mold is used, positioning rods are pulled out, a roller and a moving column are pushed to enter the inside of a loading groove, and the positioning rods are inserted into second through holes. The roller is convenient to store and use, normal use of the mold is not affected, and convenience and diversity of use of the mold are improved.

Owner:宁波航天模塑有限公司

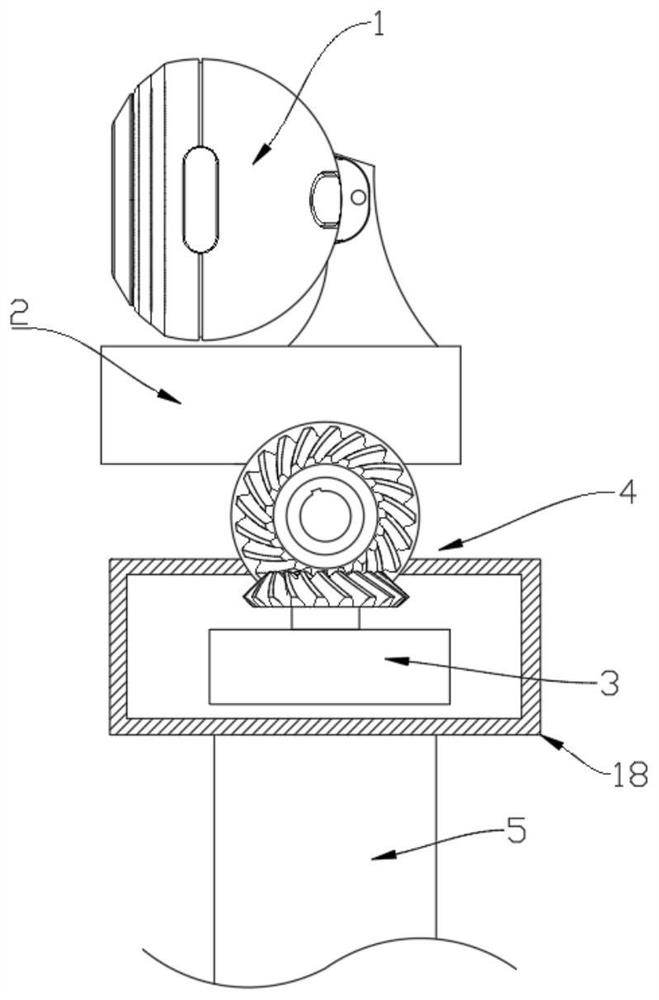

Intelligent construction site comprehensive safety management remote monitoring device based on BIM model

PendingCN110351468AQuick and easy positioningAdjust the monitoring rangeTelevision system detailsNon-rotating vibration suppressionDrive motorSurveillance camera

The invention relates to the technical field of intelligent construction sites and further discloses an intelligent construction site comprehensive safety management remote monitoring device based onthe BIM model. The device comprises a mounting plate, a bottom plate is fixedly clamped at the upper end of the mounting plate; the center of the upper end of the bottom plate is rotationally connected with a rotating rod through a ball bearing. The upper end of the rotating rod is fixedly connected with a supporting plate; the rod wall of the rotating rod is fixedly sleeved with a first driven bevel gear; a driving motor is fixedly connected to the upper end of the bottom plate, a first driving bevel gear engaged with the first driven bevel gear is fixedly connected to an output shaft of thedriving motor, a U-shaped supporting plate is fixedly connected to the upper end of the supporting plate, and the side walls of the left and right opposite sides of the U-shaped supporting plate are rotationally connected with the same protective barrel through rotating shafts. According to the invention, the monitoring range of the monitoring camera can be adjusted, so that people can carry out remote monitoring according to needs.

Owner:CHINA MCC17 GRP

Microscopic ocular protective structure for oral operation

InactiveCN109164565APlay a protective effectAvoid damageMicroscopesMagnifying glassesOral operationEngineering

The invention discloses a microscopic ocular protective structure for an oral operation, comprising an ocular mounting head, an ocular is inserted and connected in a mounting hole at the top of the ocular mounting head, an annular slot is formed in the outer end of the top surface of the ocular mounting head, an annular drum is inserted and connected in the annular slot in a sliding way, a plurality of locating slots are formed in the two ends of the annular drum, an annular groove is formed in the upper part of the outer wall of the ocular mounting head, a turning ring is rotatably clamped and connected in the annular groove, spring slots are formed in the two ends of an inner circle of the turning ring, springs are fixedly connected in the spring slots, the free end of each spring is fixedly connected at a middle position of the side wall of a connection block, a hemispherical locating block is fixedly arranged at the other side of the connection block, the hemispherical locating block is movably clamped and connected in the locating slots by virtue of a through slot communicated with the annular slot, and when the annular drum can cover the ocular, the turning ring is rotated, and the hemispherical locating block is clamped and connected with the locating slots by virtue of the through slot, so that the annular drum realizes protective effect on the ocular, and personnel isprevented from touching the ocular and damaging the ocular carelessly.

Owner:ZHENJIANG XINTIAN MEDICAL DEVICES

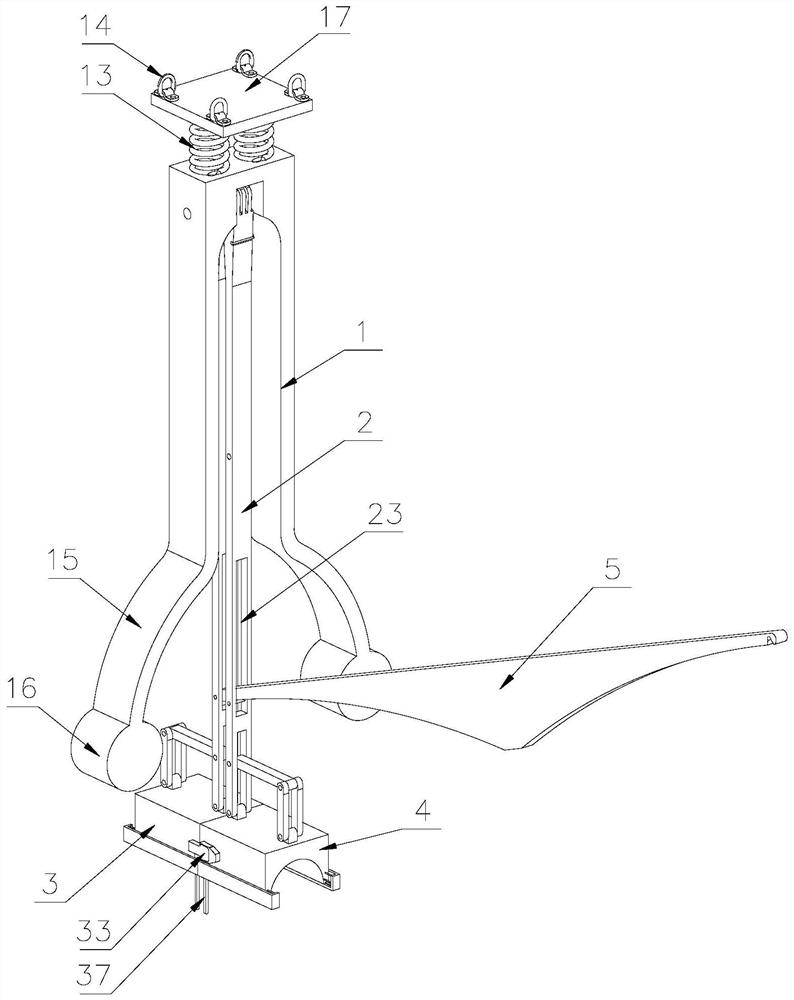

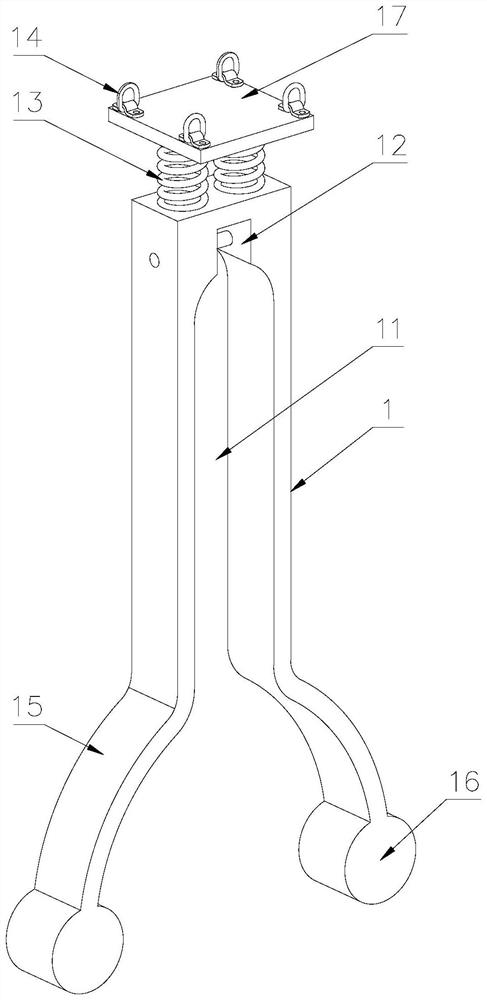

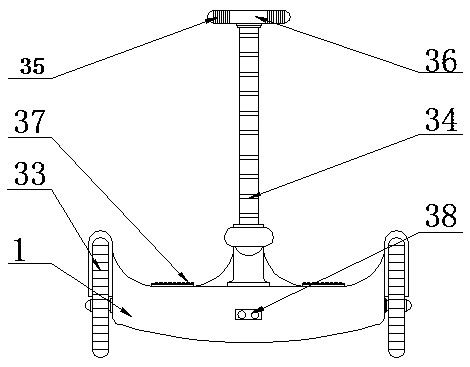

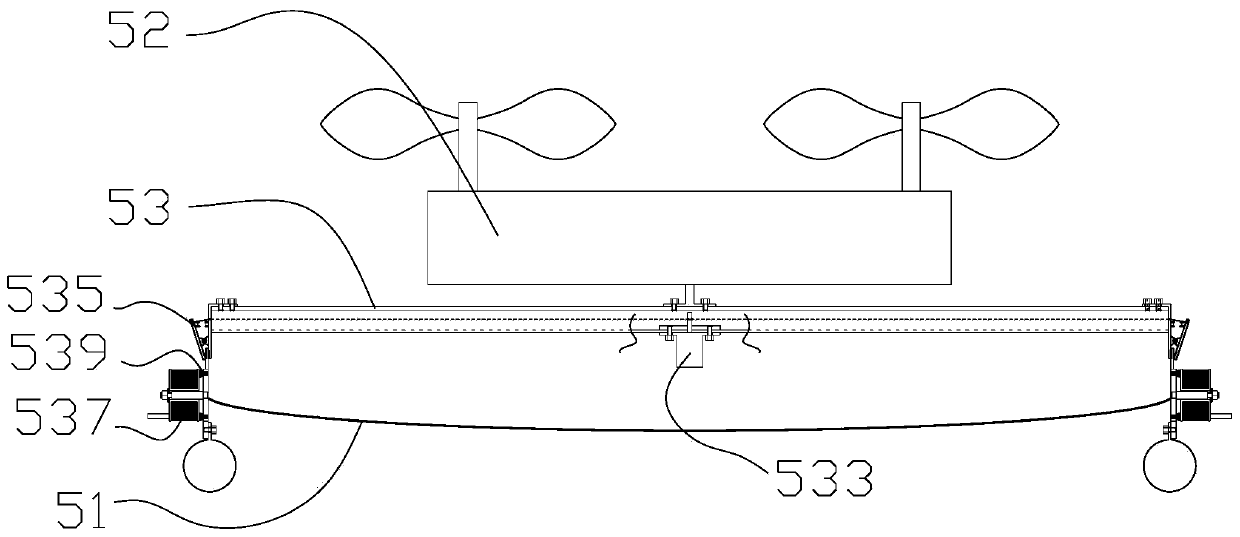

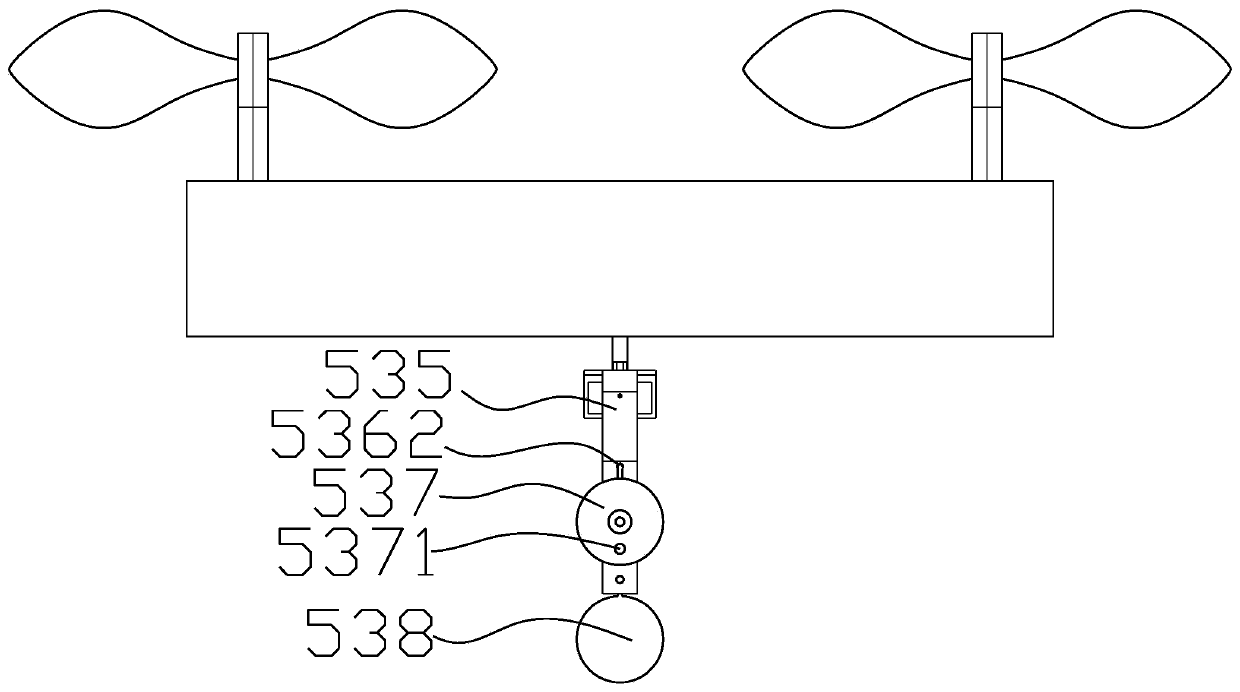

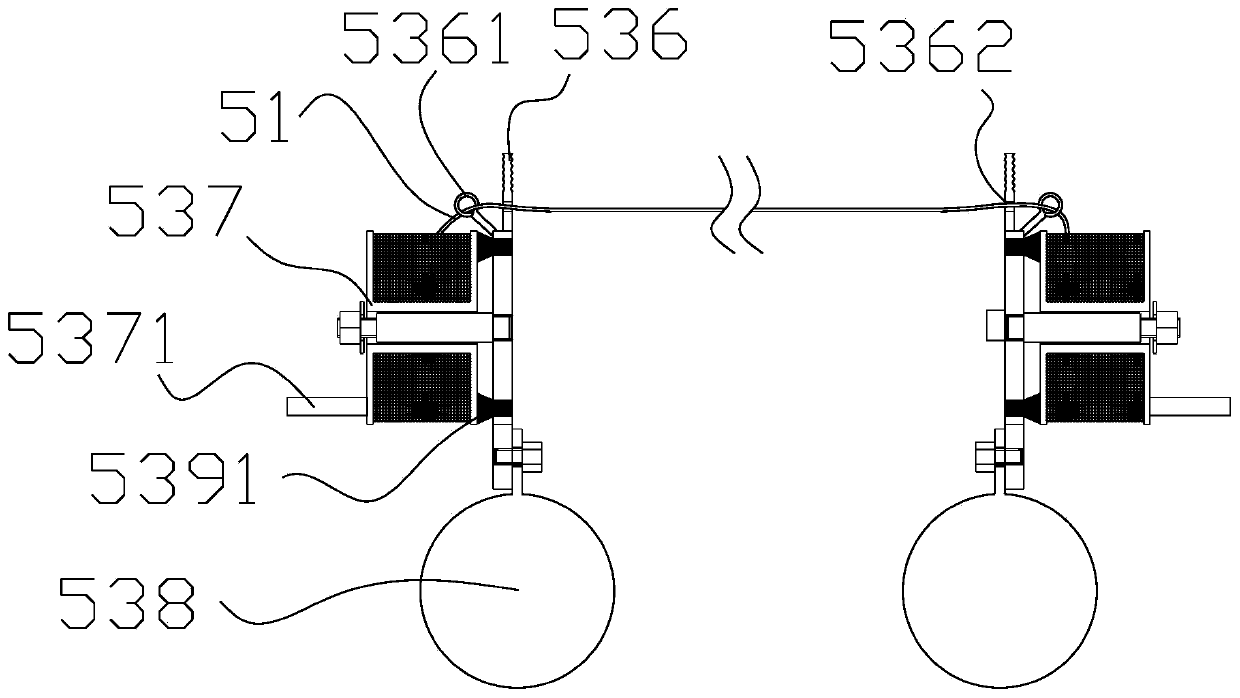

Unmanned aerial vehicle carried high-altitude cable foreign matter cleaning device

ActiveCN112217142AImprove cleaning efficiencyAvoid damageAircraft componentsVibration suppression adjustmentsForeign matterUncrewed vehicle

The invention discloses an unmanned aerial vehicle carried high-altitude cable foreign matter cleaning device which comprises a hanging bracket and clamping arms symmetrically arranged on the two sides of the hanging bracket, and an unmanned aerial vehicle is connected with a hanging ring through a connecting piece. U-shaped grooves are formed in the middle of the hanging bracket, and the clampingarms on the two sides are connected through torsional springs. A first clamping block is hinged to the lower end of the left clamping arm, and a second clamping block is hinged to the lower end of the right clamping arm; one end of the top plate is rotatably connected with the first through groove, a clamping groove is formed in the other end of the top plate, a clamping rod is arranged in the first through groove in the right side, and the clamping groove is clamped to the clamping rod when the clamping arms are unfolded. The device is hoisted and landed on the cable by using the unmanned aerial vehicle, one end of the top plate is separated from the clamping rod of the clamping arm under the action of the supporting force of the cable, the clamping arm is contracted under the action ofthe elastic force of the torsional spring, and the first clamping block and the second clamping block clamp and clean foreign matters on the cable, so that the labor intensity of operators is reduced,and the foreign matter cleaning efficiency is improved; and the cable is prevented from being damaged during foreign matter cleaning.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

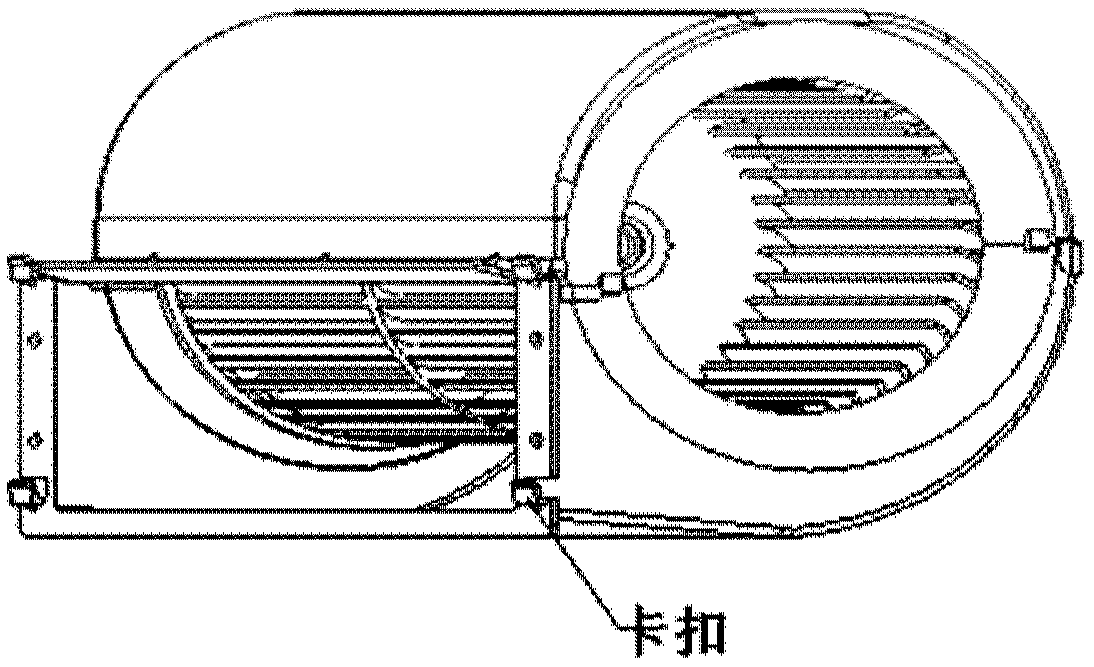

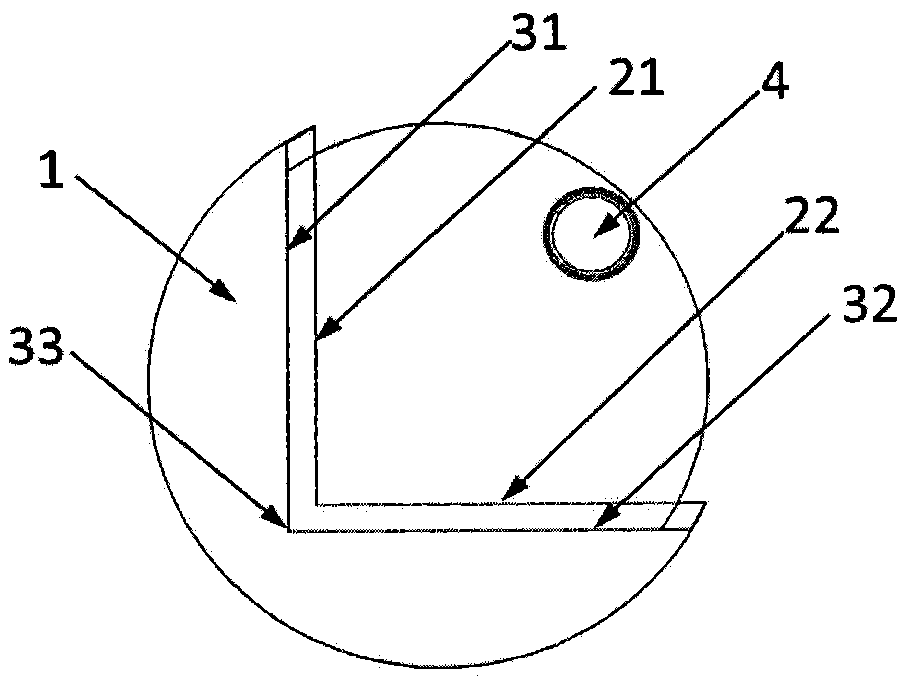

Volute component and air conditioner

PendingCN109611379AAchieving enhanced fixationIn line with operating habitsPump componentsPumpsEngineering

The invention provides a volute component which comprises a volute and a volute fixing piece; the volute comprises a first fixing piece; the volute fixing piece comprises at least one second fixing piece; each of the left side and the right side of the first fixing piece comprises at least one block button; each of the left side and the right side of the second fixing piece comprises at least oneblock button hole; and the block buttons are clamped into the block button holes from top to bottom. For the a volute component provided by the invention, through mutual matching of at least two blockbuttons of the first fixing piece and at least two block button holes of the second fixing piece, fixing of the volute and the volute fixing piece can be realized.

Owner:NINGBO AUX ELECTRIC +1

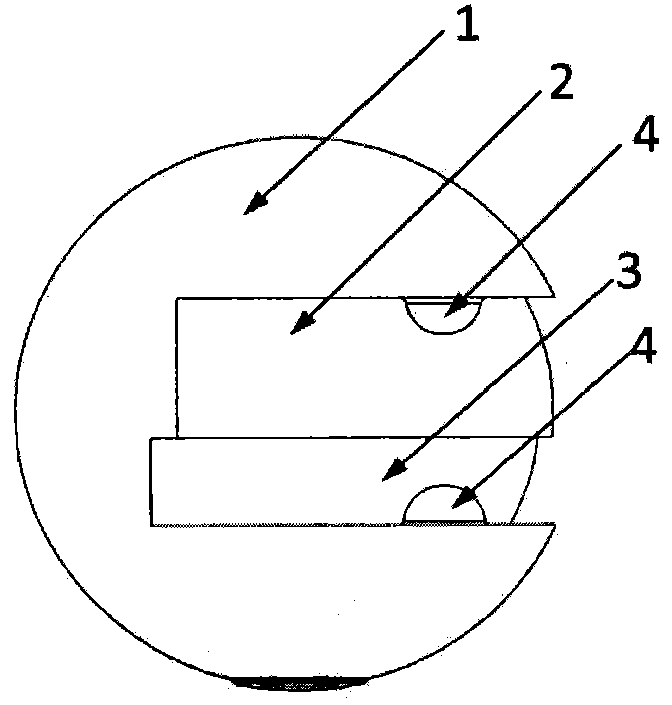

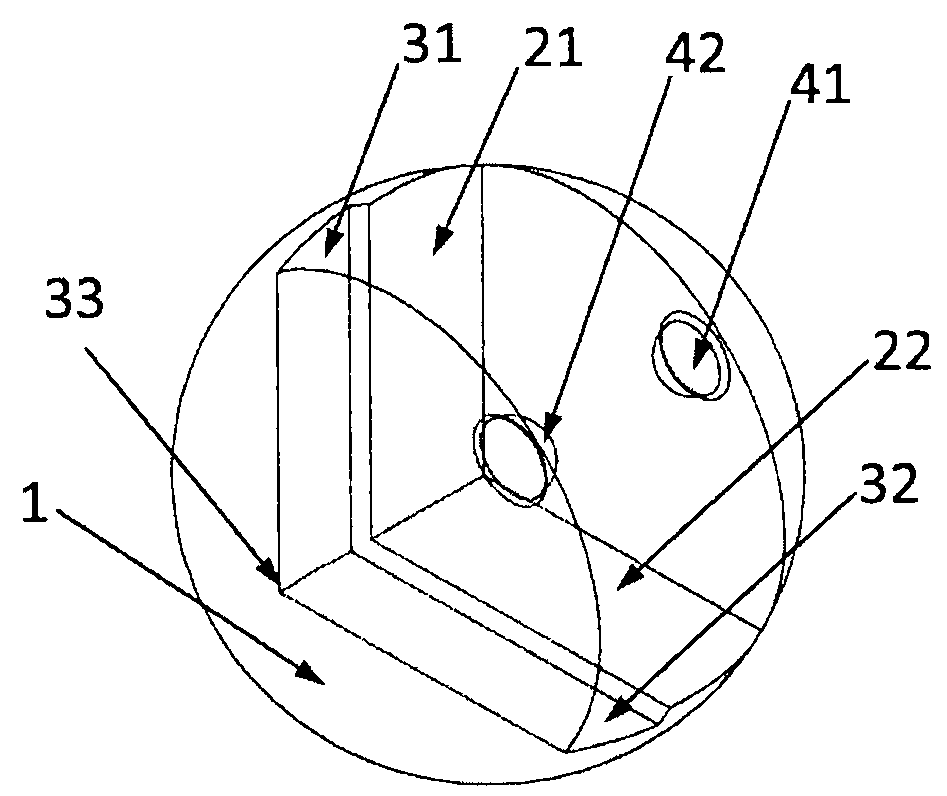

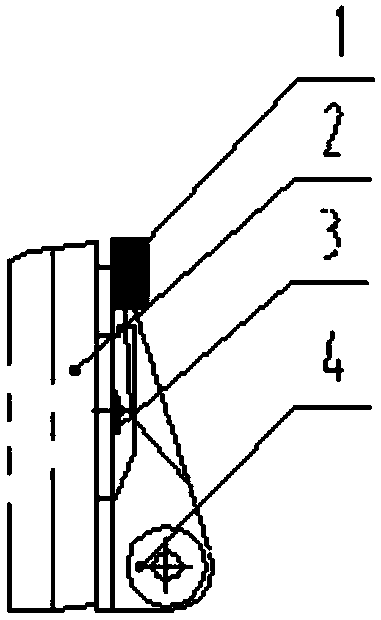

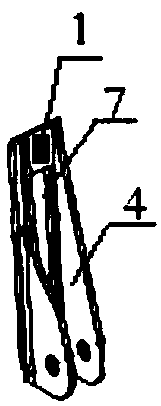

Impact preventing body for windows

ActiveCN105275361AAvoid injuryRealize all-round protectionSpecial door/window arrangementsEmbedmentEngineering

The invention relates to an impact preventing body for windows, and belongs to the field of protective devices for window corners. The impact preventing body for windows comprises an impact preventing body, a groove and a locking member. The impact preventing body is provided with the groove, a longwise surface, a transversal surface and two side surfaces are formed in the groove, the longwise surface and the transversal surface mutually intersect and respectively interest with the two side surfaces. The groove and a window frame having corners are connected in embedment, the groove bottom in the groove matches the corners. The side surfaces of the grooves are provided with locking members, the locking members are protrusions, and the locking members extend from outer side faces in the window frame to recesses of glass in a window. The impact preventing body for windows can effectively buffer the impact force, and damages to the people who impacts on a window can be reduced.

Owner:王杰

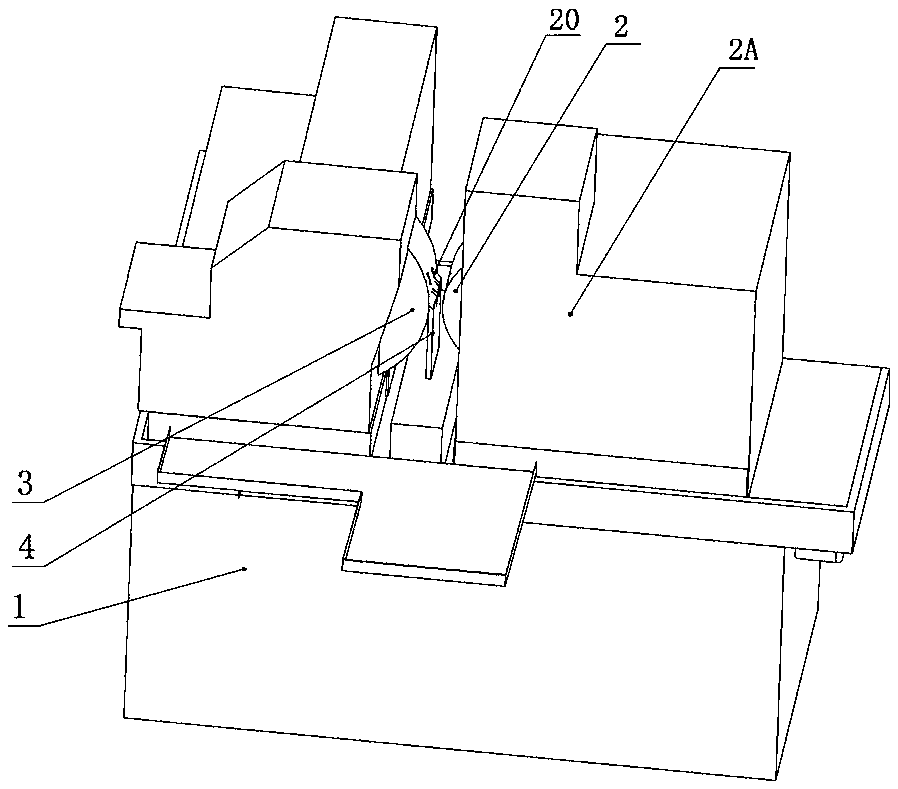

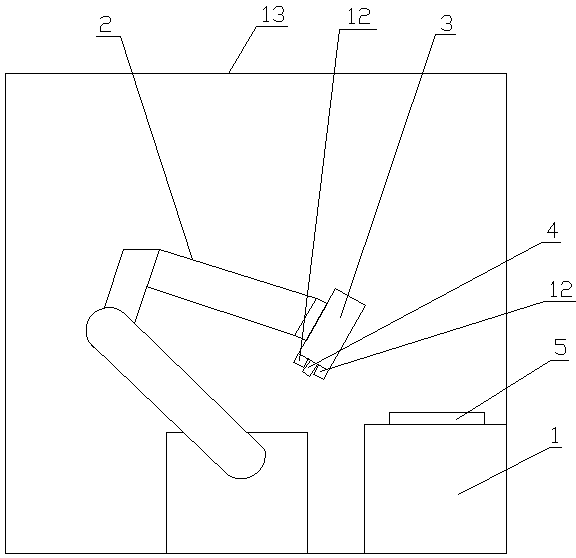

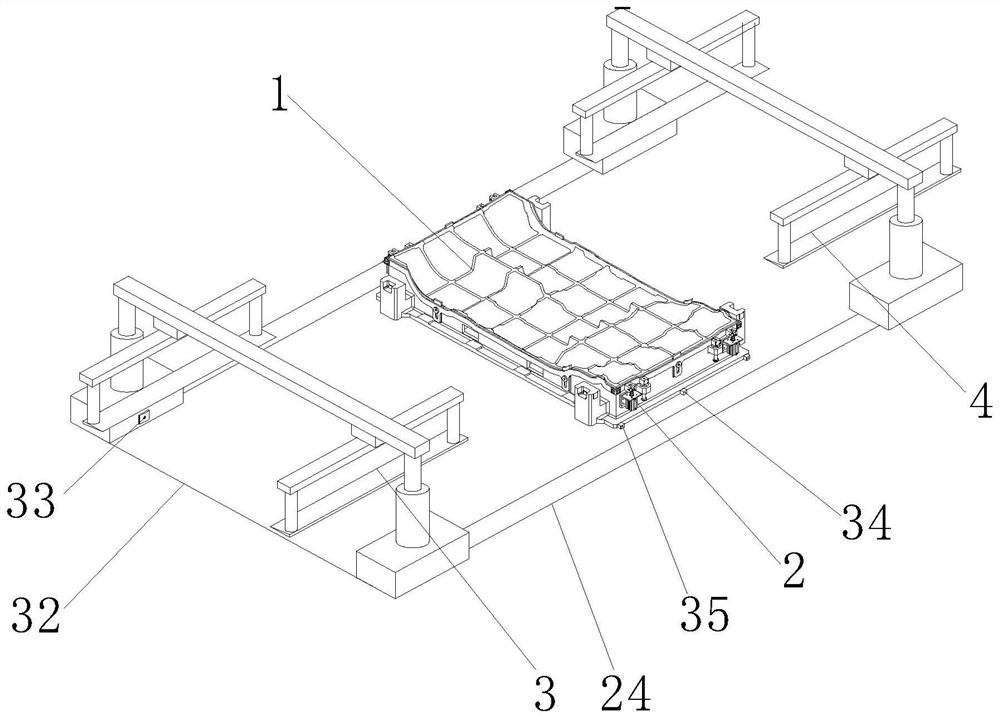

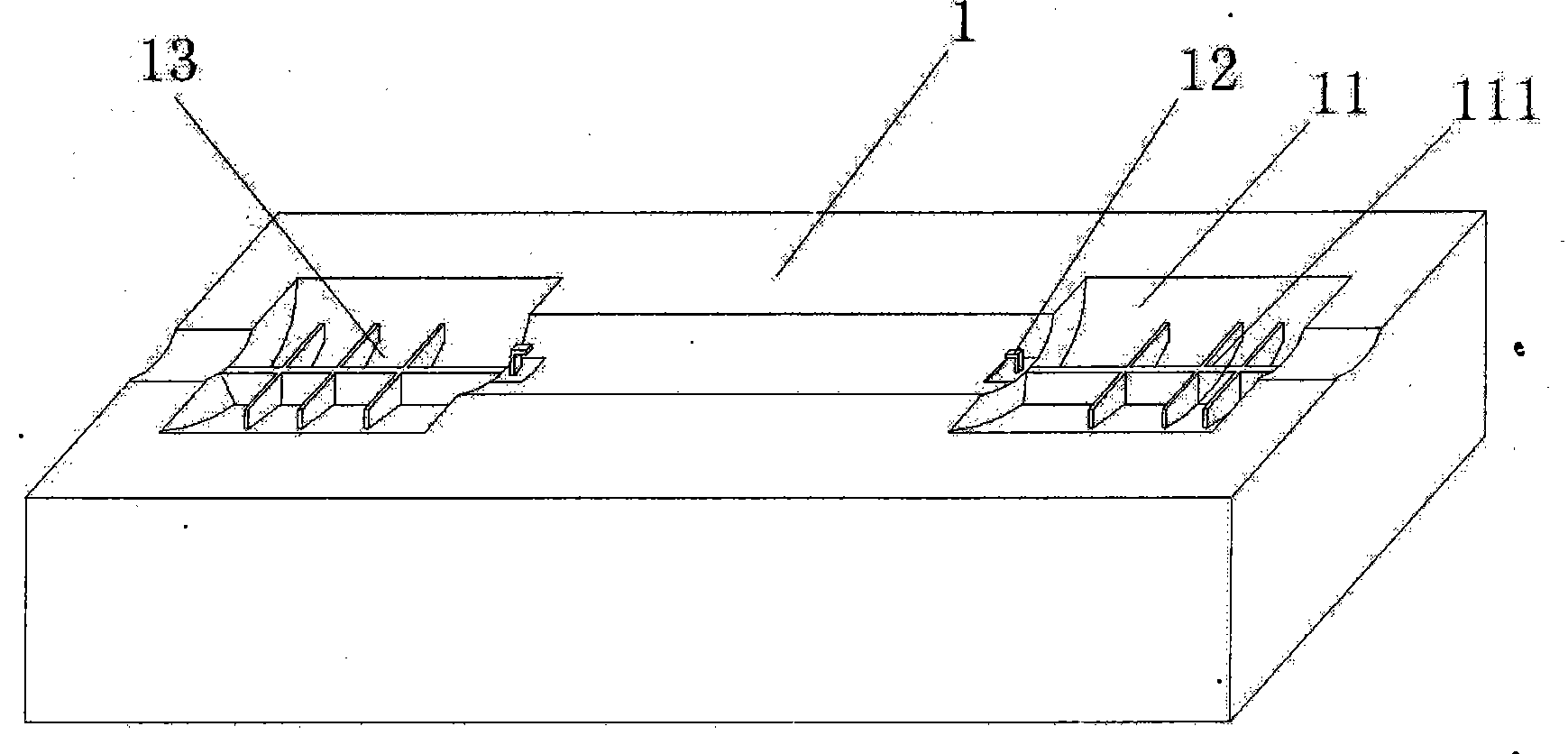

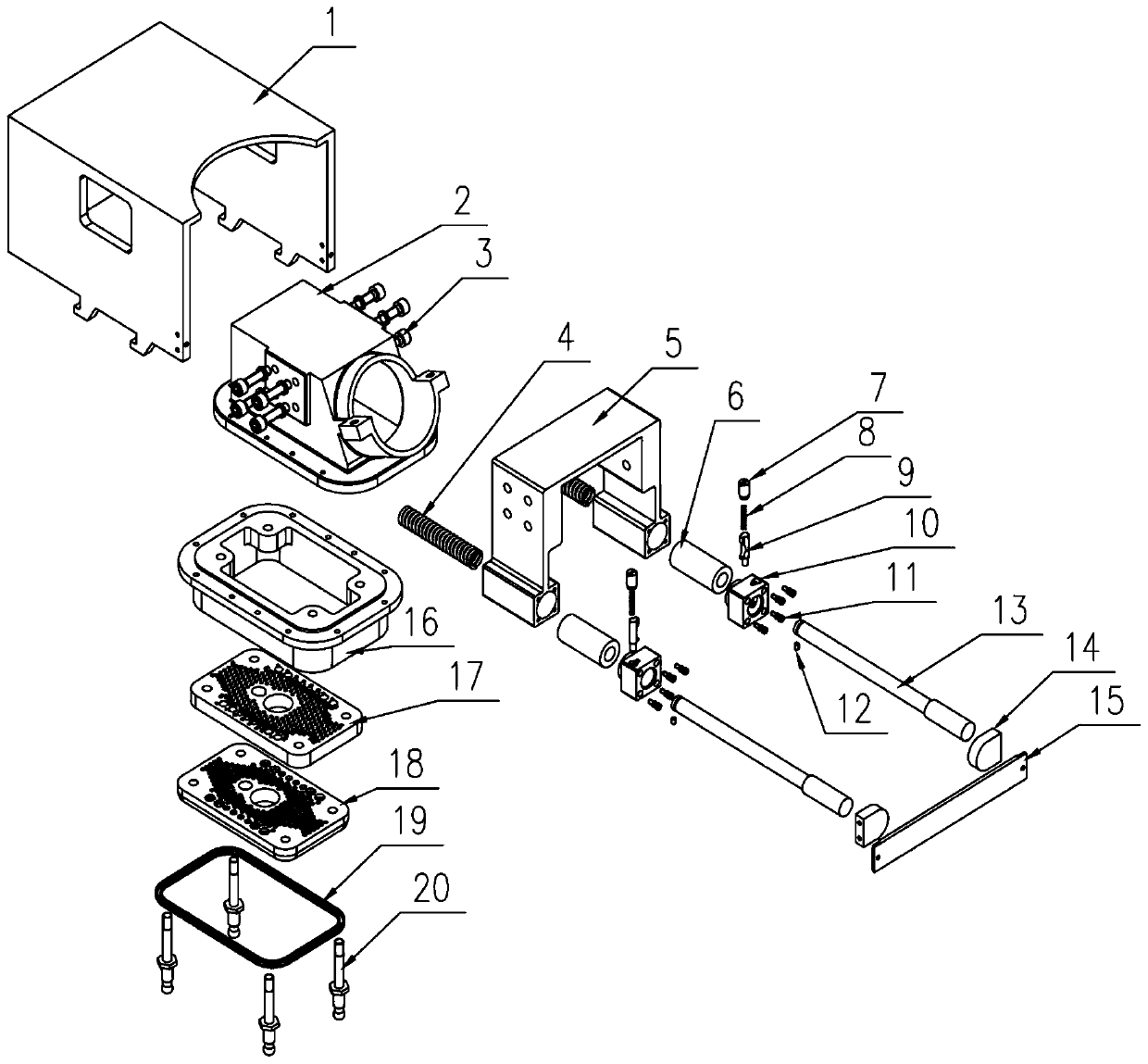

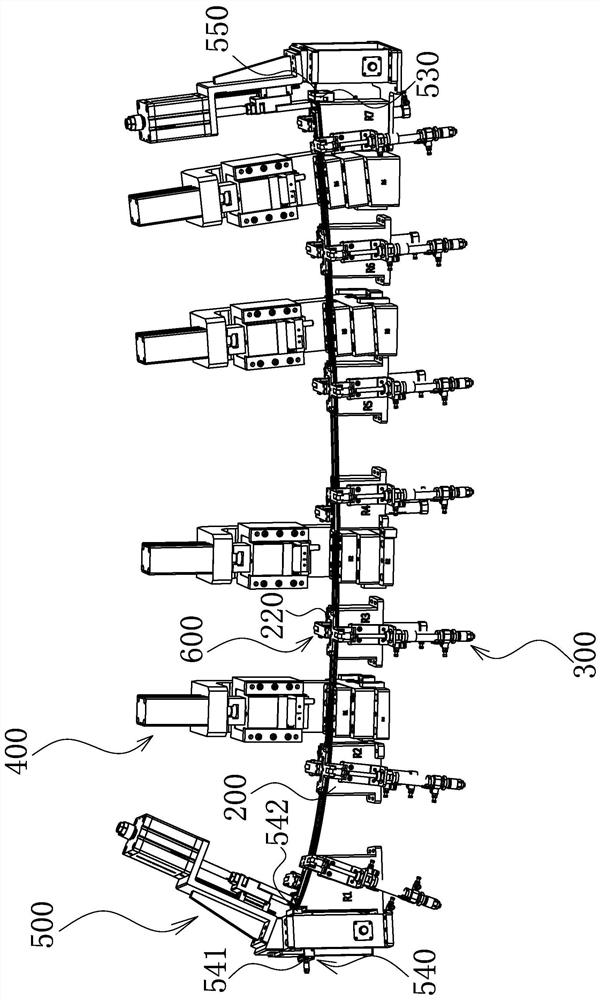

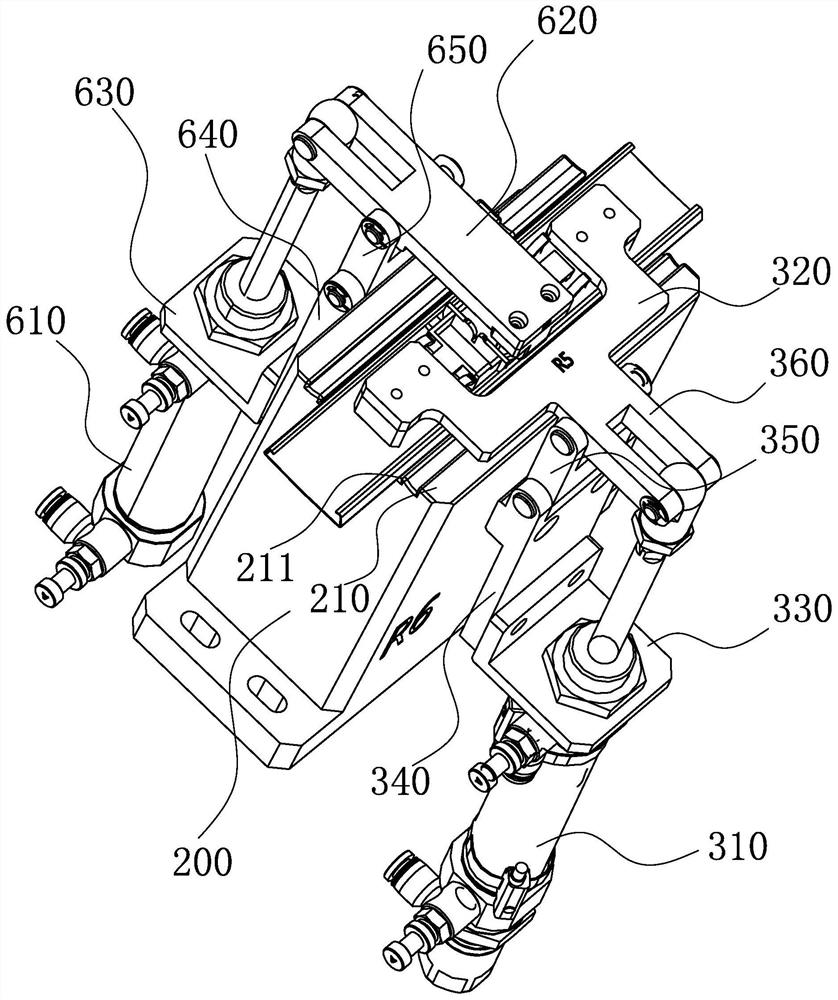

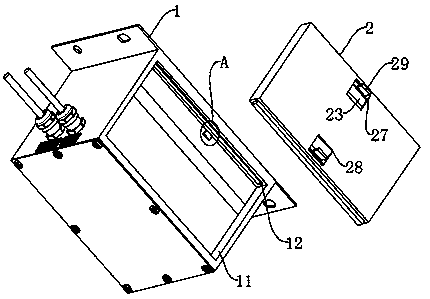

Automatic clamping connecting seal strip device for panoramic skylight glass

InactiveCN109333043AAccurate snap connectionGood effectMetal working apparatusEngineeringMechanical engineering

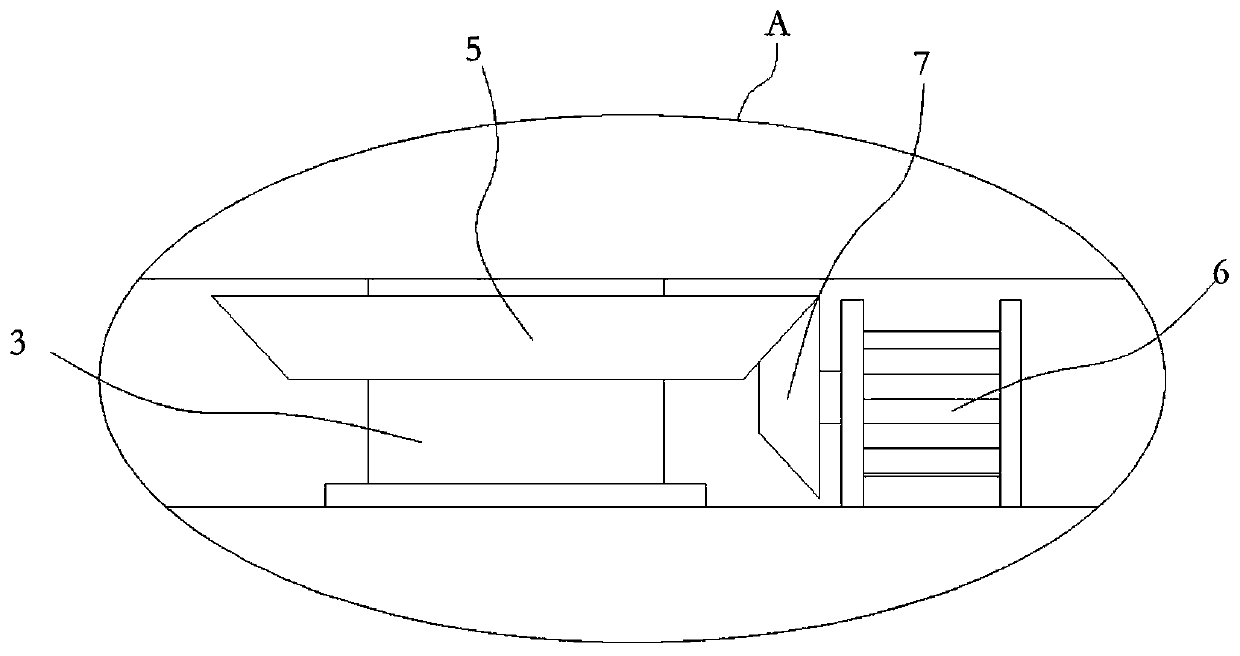

The invention aims to provide an automatic clamping connecting seal strip device for panoramic skylight glass. The skylight glass is placed on a tool plate from an opening of the right side of a working frame after the edges of the skylight glass is manually covered with seal strips, the skylight glass is supported through first support blocks and second support blocks, the skylight glass is fixedto suction cups in a sucking mode, and then a robot drives a clamping connecting cylinder to adjust positions. The clamping cylinder drives and pushes a clamping head to clamp the seal strips, two positioning blocks are arranged at the edges of the skylight glass in a clamping mode, the clamping head is pushed to clamp the seal strips, clamping is precise and effects are good, manually clamping is not needed absolutely, the production efficiency is greatly improved, and the automatic clamping connecting seal strip device for the panoramic skylight glass is suitable for production.

Owner:WUHU MOTIONTEC AUTOMOTIVE

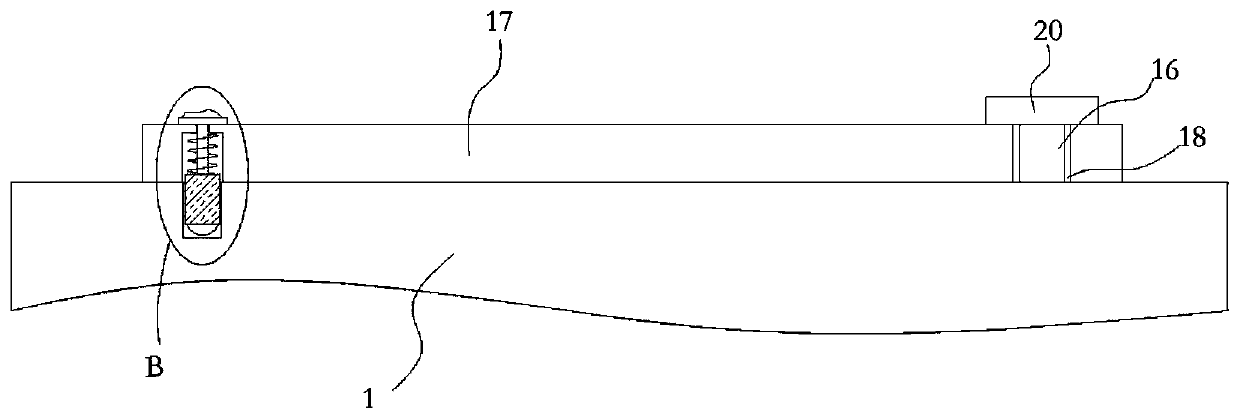

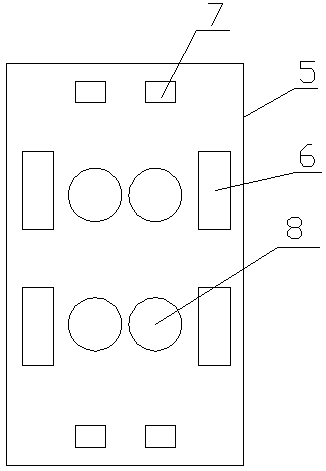

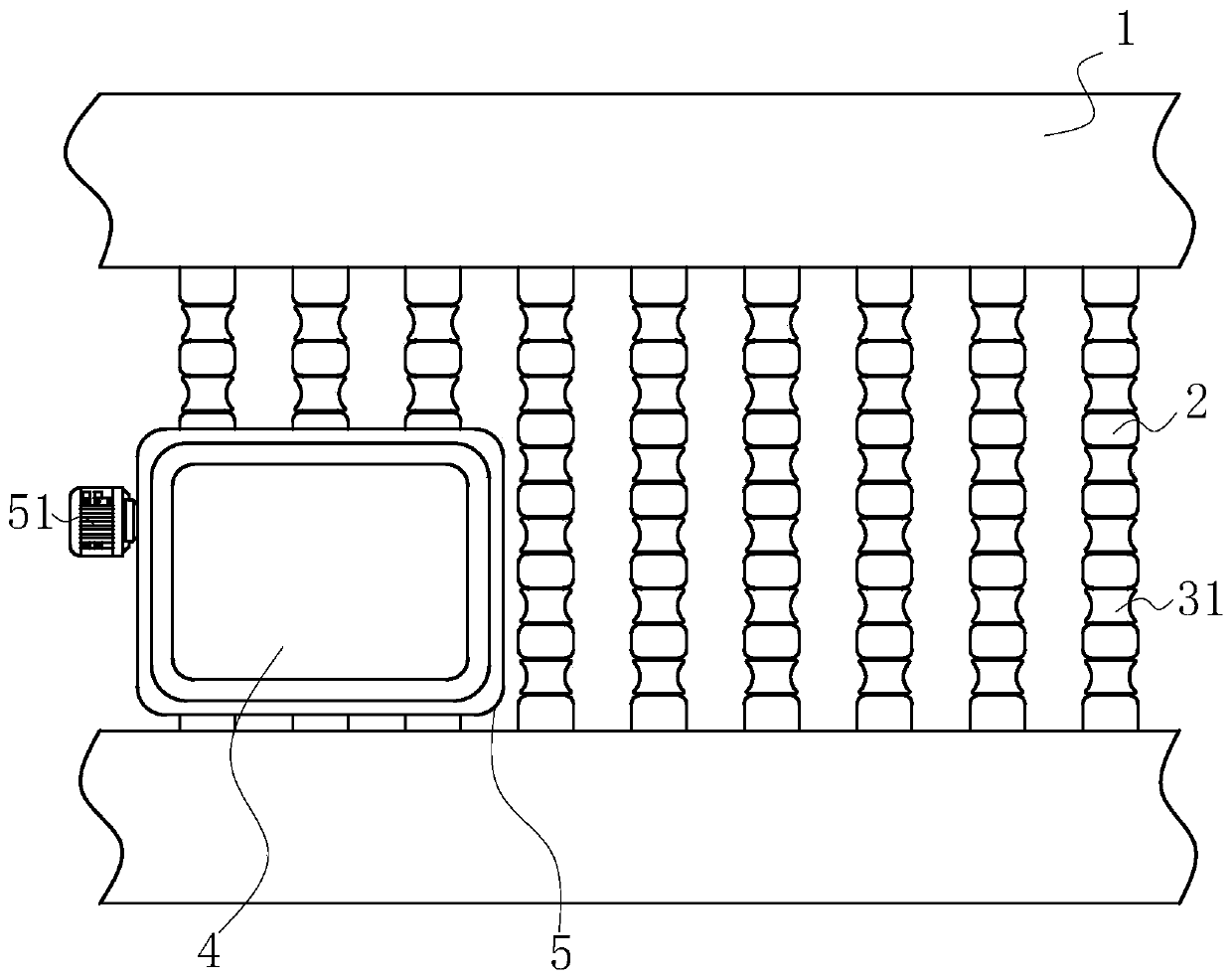

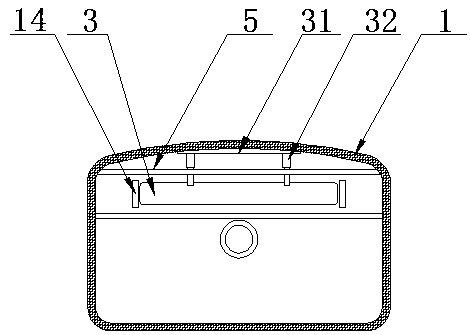

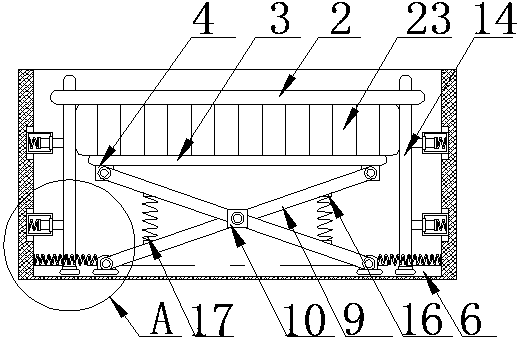

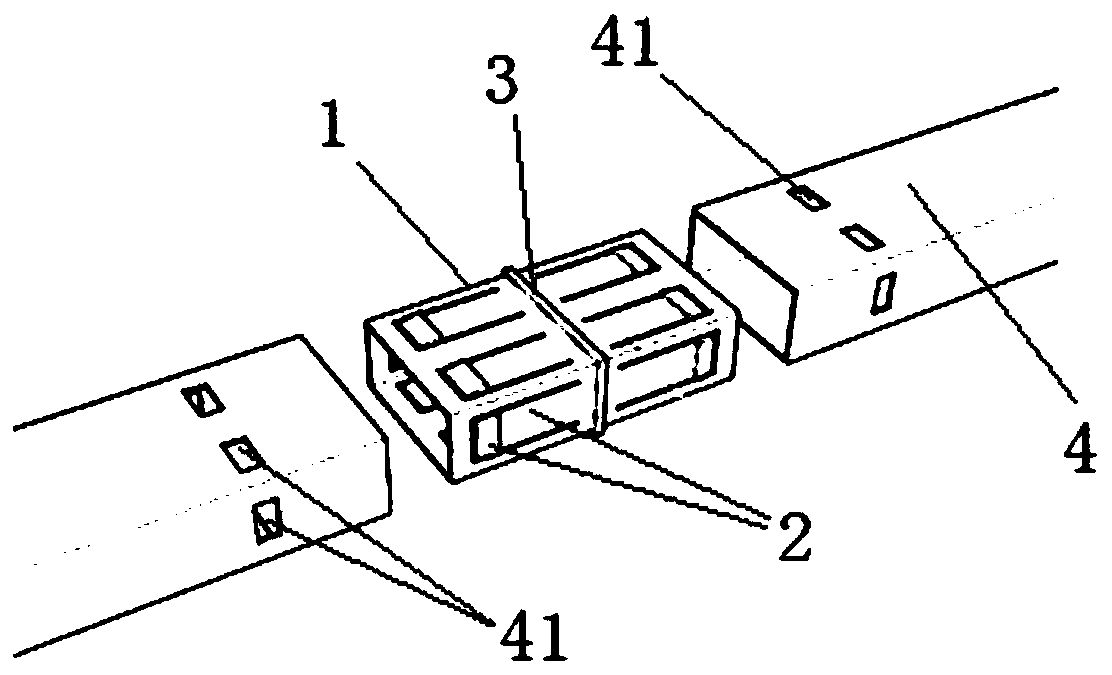

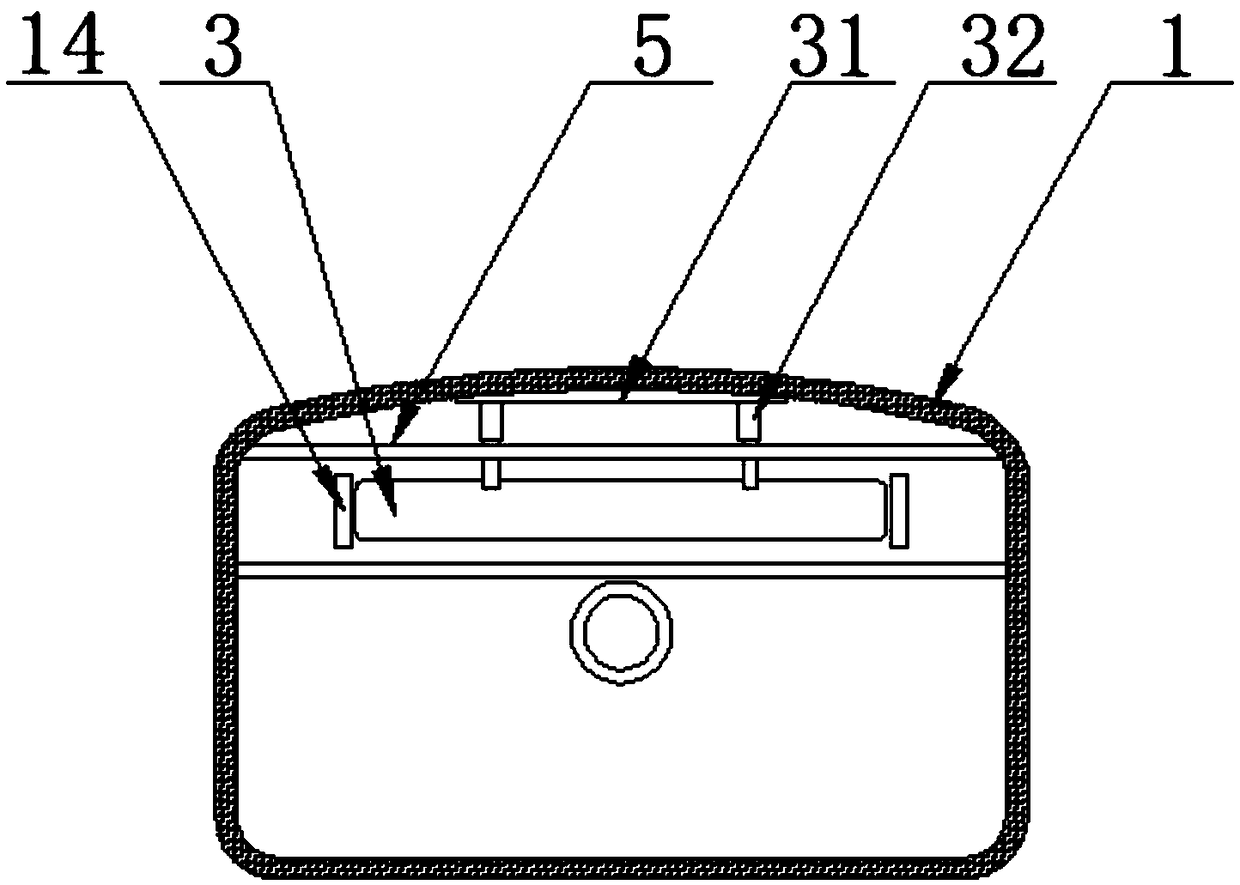

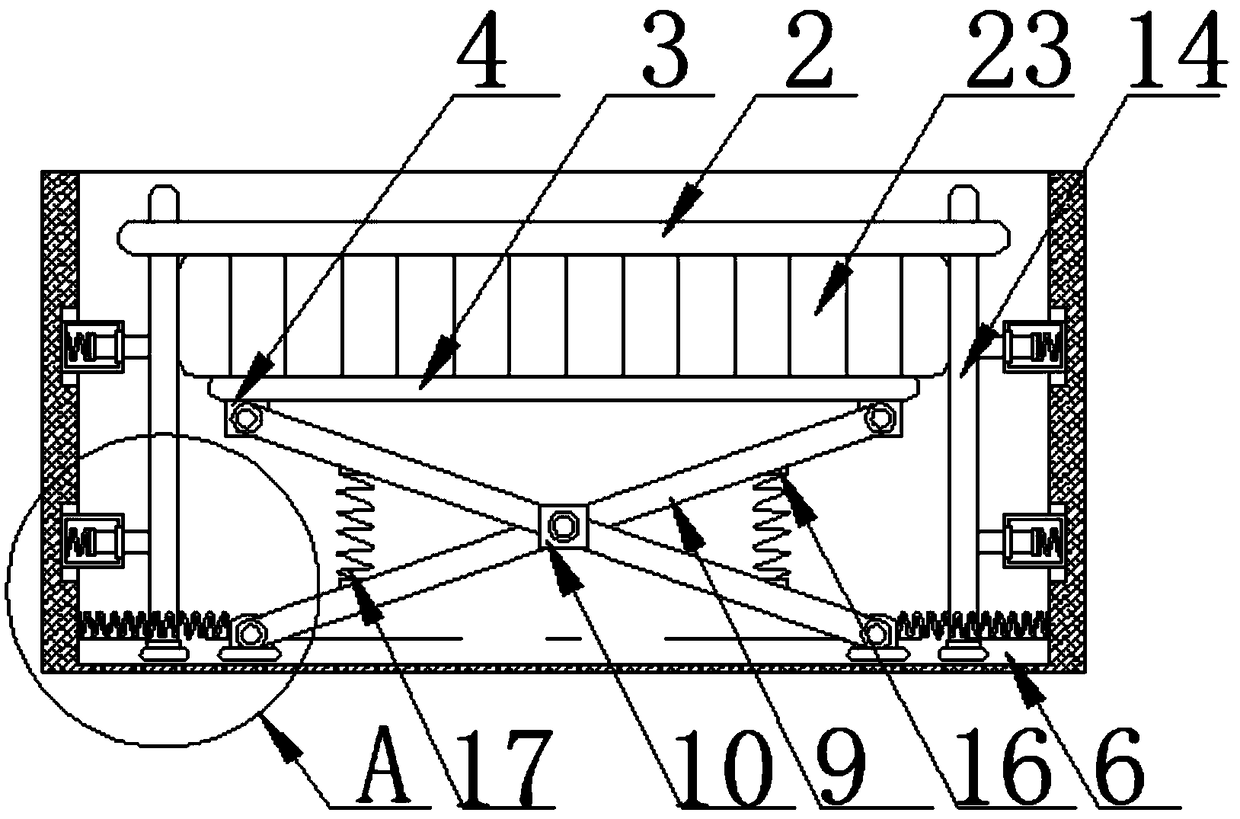

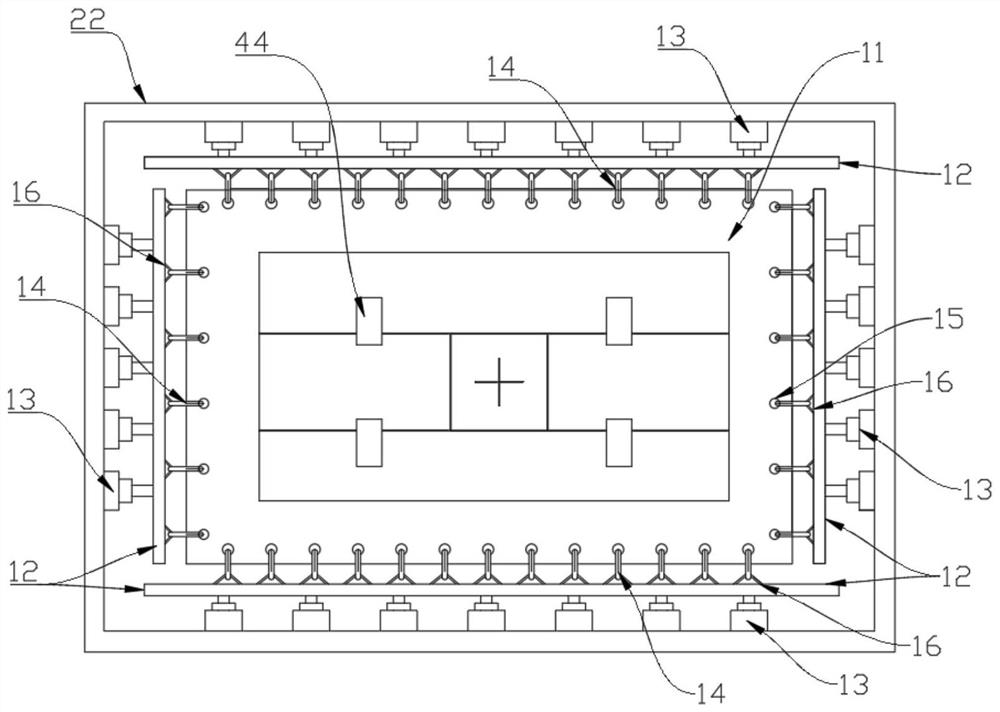

Shoemaking production line with independent working tooling plate

ActiveCN110419824AAccurate snap connectionAvoid jitterShoemaking devicesProduction lineTransmission belt

The invention belongs to the field of shoemaking production equipment, and in particular relates to a shoemaking production line with an independent working tooling plate. The shoemaking production line with the independent working tooling plate comprises rectangular plates, a transmission shaft, installation grooves, the tooling plate and a moving mechanism; the two rectangular plates are arranged in parallel; the inner walls of the rectangular plates are connected to the transmission shaft uniformly and rotatably; the installation grooves are uniformly arranged in the wall of the transmission shaft; the tooling plate is arranged over the transmission shaft; the installation grooves are annular; sliding rods are fixedly installed on the lower ends at front and rear sides of the tooling plate; the moving mechanism is arranged in the tooling plate; the moving mechanism comprises a motor, an electric telescopic rod, a transmission belt wheel, a limiting pipe, a rotating shaft, a roller and a clamping plate; the motor is glidingly installed in the left end wall of the tooling plate; and the right end of the motor is rotatably connected to the rotating shaft. The shoemaking productionline with the independent working tooling plate in the invention is mainly used for solving the problems that the shoemaking production line in the prior art is relatively high in labour intensity ofworkers and easy to fatigue and the production efficiency is influenced due to line stopping recycling when defective goods appear in the production process.

Owner:浙江名将鞋业有限公司

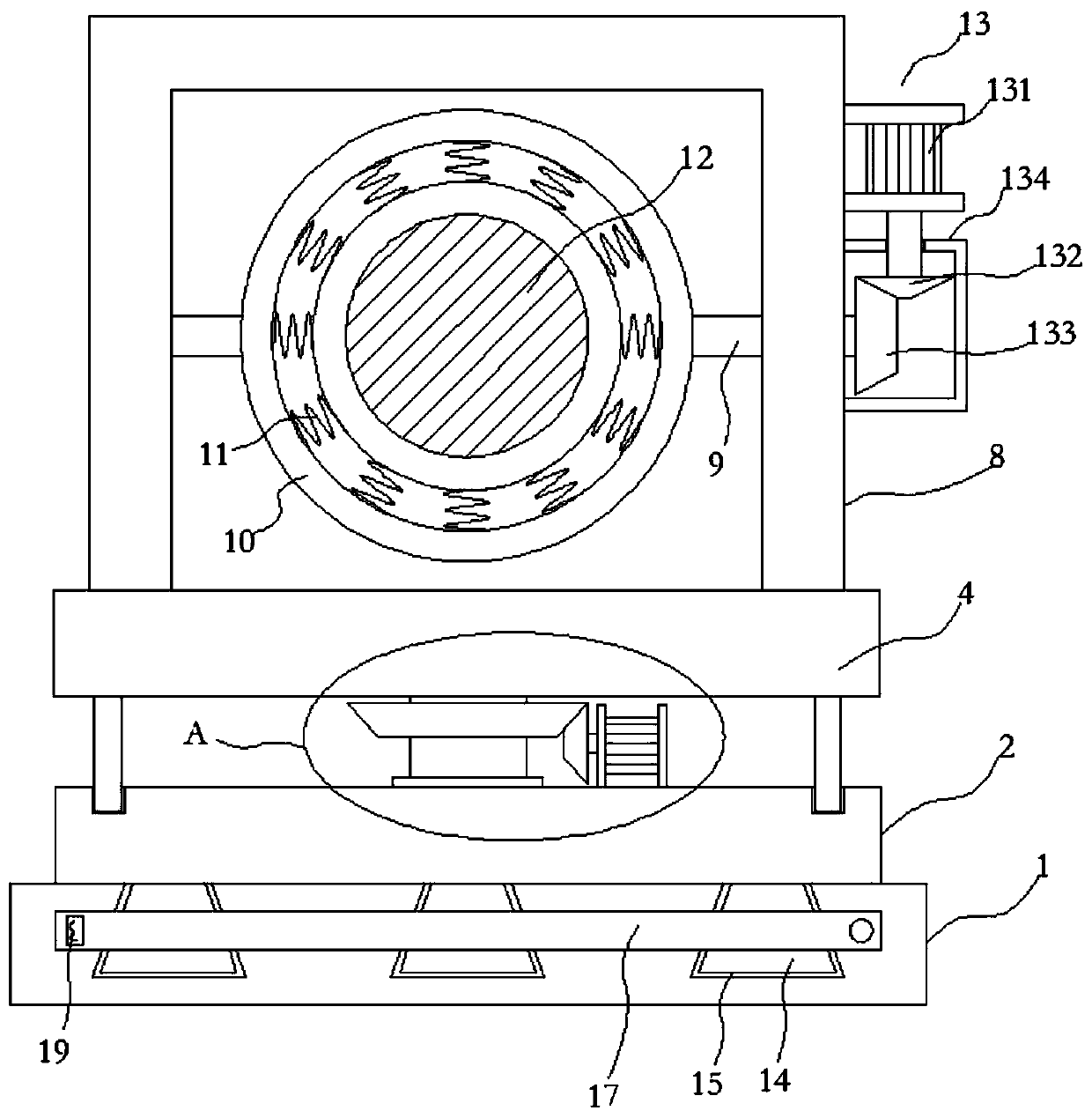

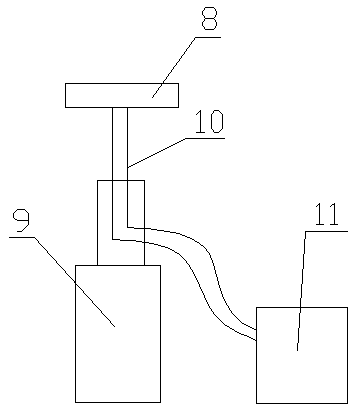

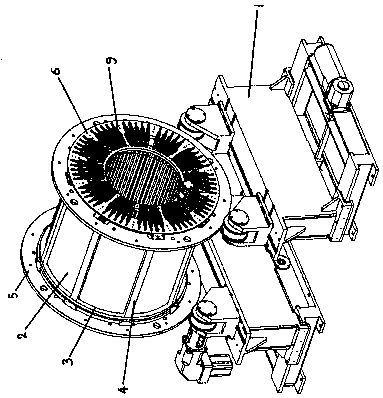

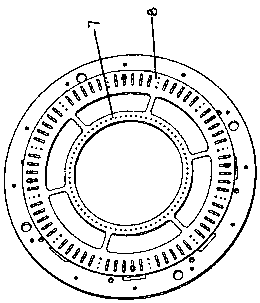

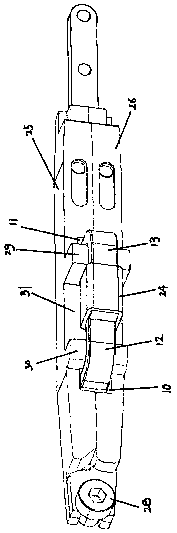

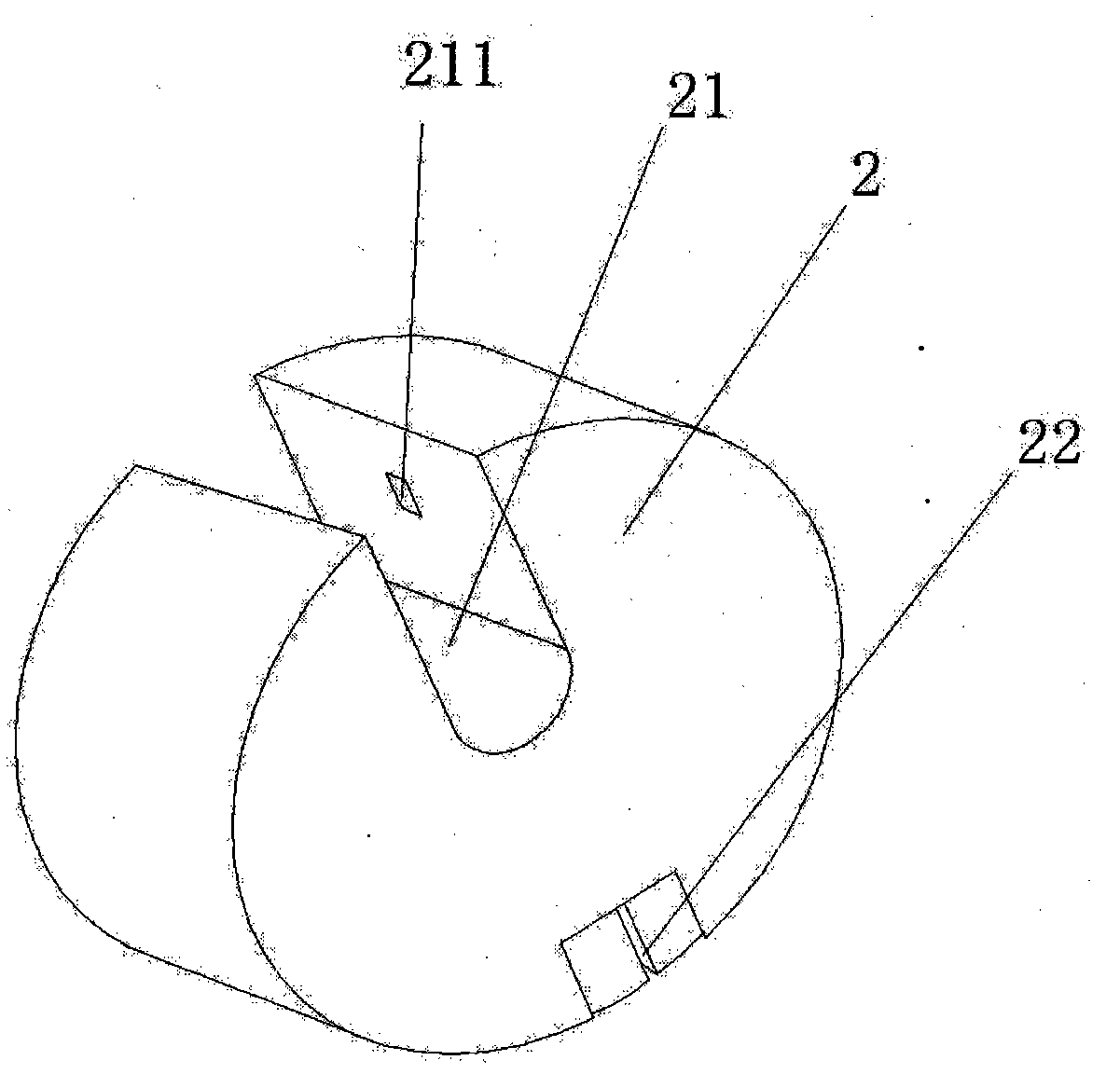

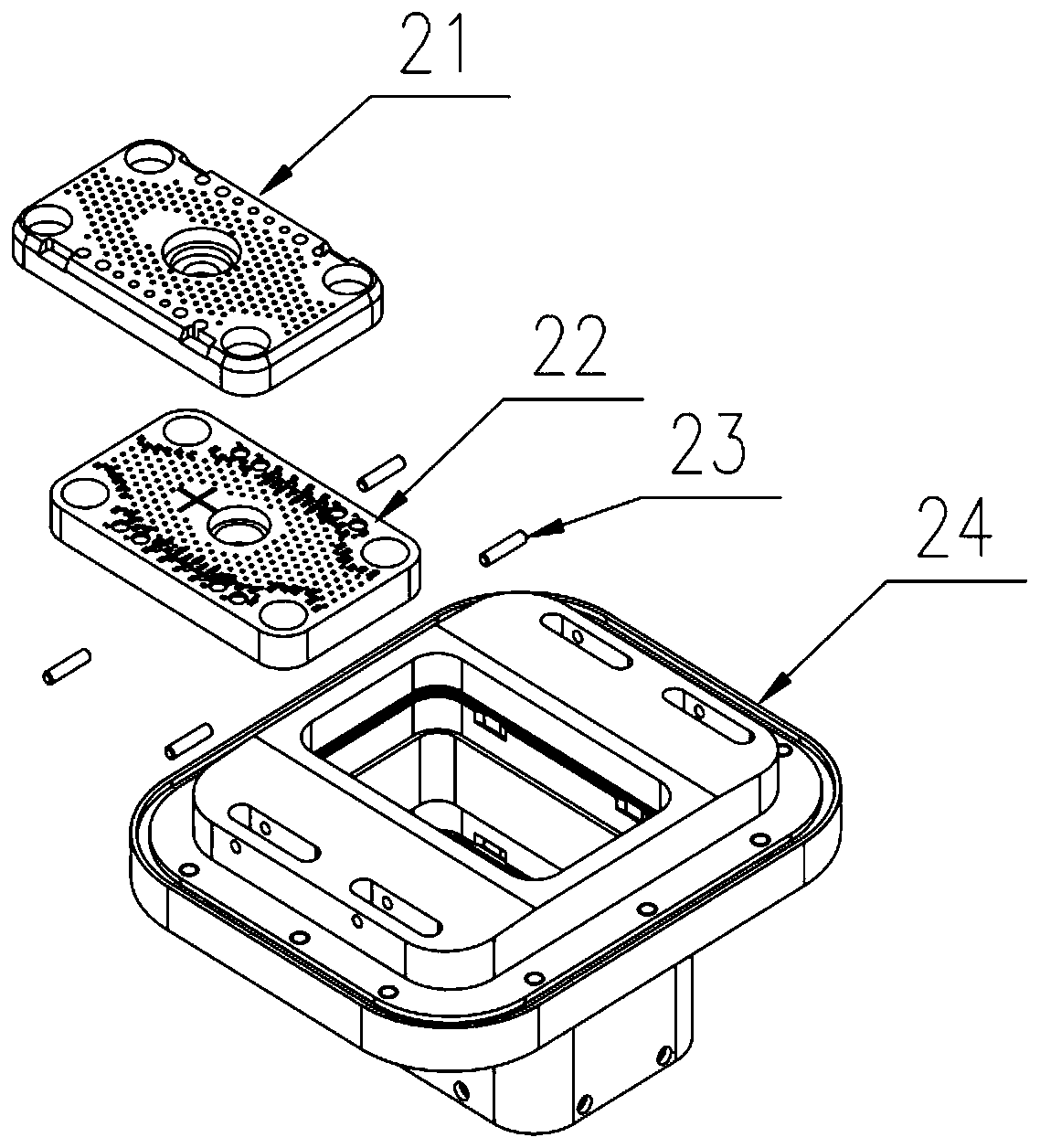

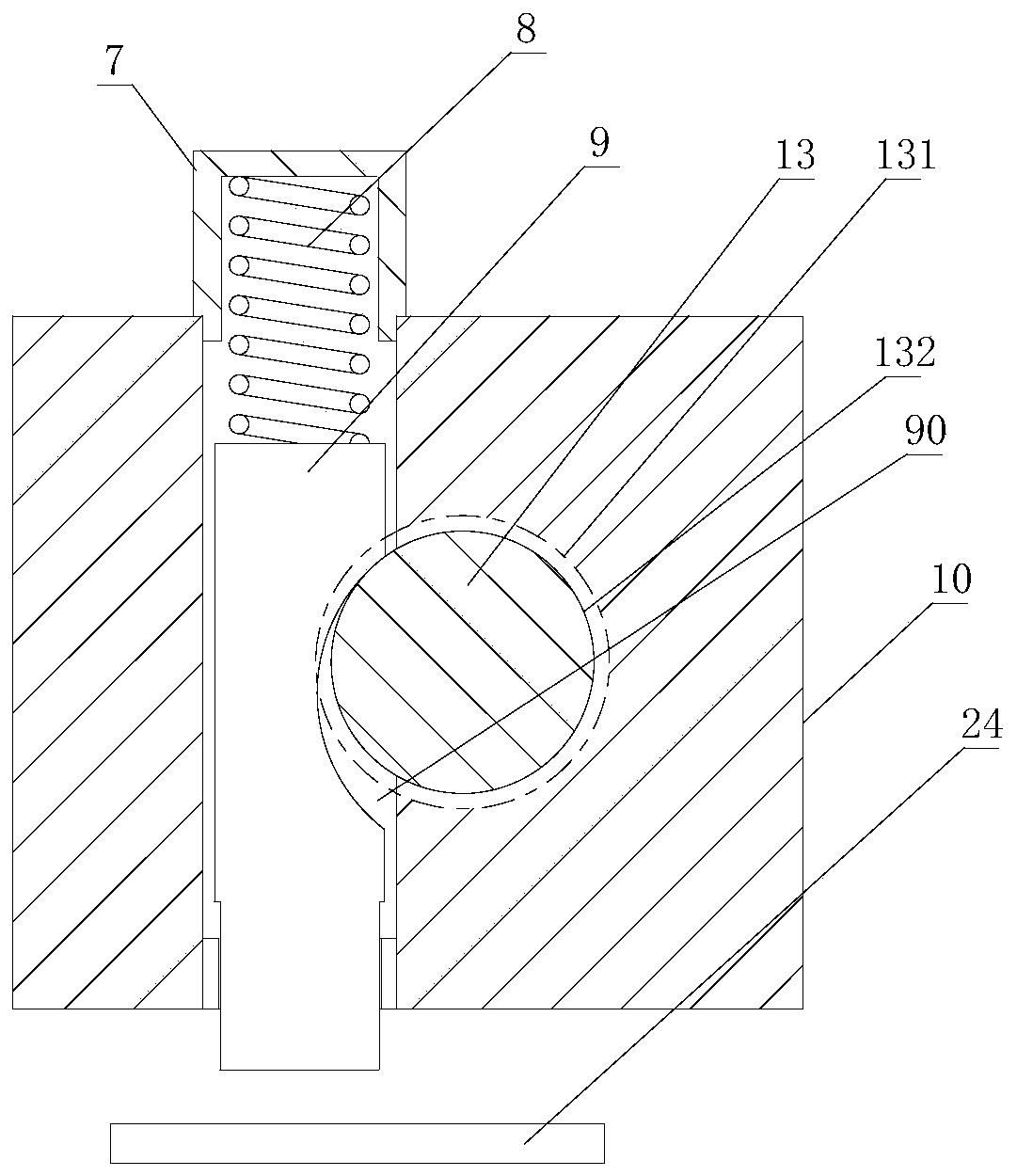

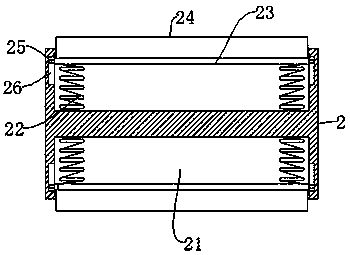

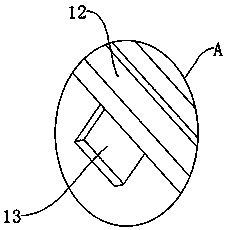

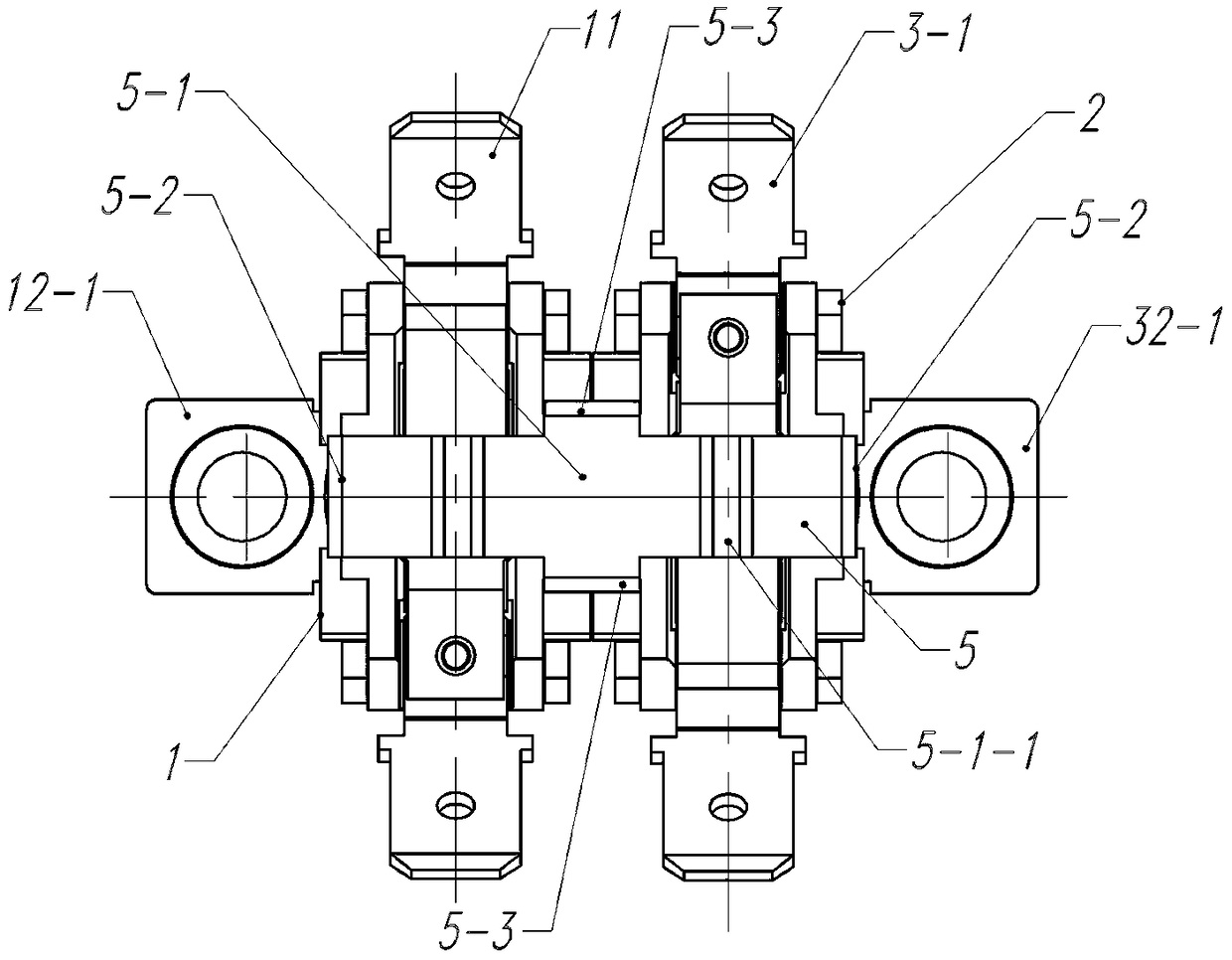

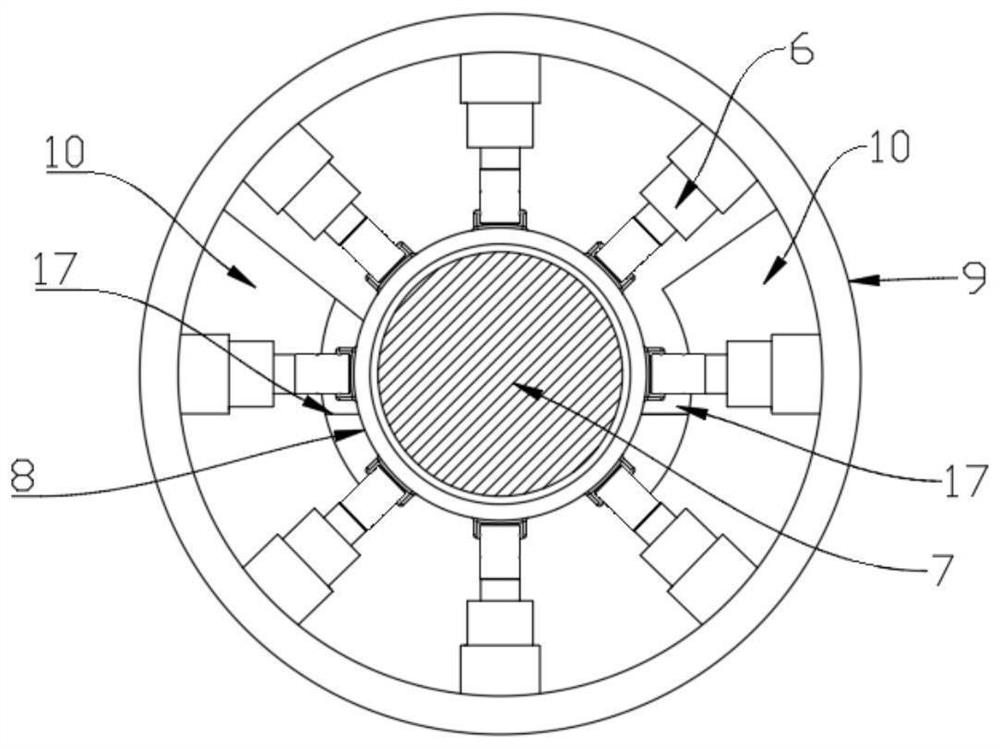

Occlusion mechanism and occlusion method after bending of coil leading-out wire end

PendingCN111342624AConvenient automatic welding operationPrecise positioningManufacturing dynamo-electric machinesProduction lineGeneral surgery

The invention discloses an occlusion mechanism and an occlusion method after the bending of a coil leading-out wire end, and solves the technical problem that the prior art cannot adapt to automatic production line production. Shearing the thread ends of the inner ring leading-out wires according to the splicing length, and bending outwards through an inner ring leading-out wire bending table to obtain inner ring leading-out wire bending thread ends (12); shearing the wire end of the outer ring leading-out wire according to the splicing length, and bending inwards through an outer ring leading-out wire bending table to obtain an outer ring leading-out wire bending wire end (13); a C-shaped connecting clamp (24) is buckled between the inner ring leading-out wire bending head (12) and the outer ring leading-out wire bending head (13); the jaw (23) is moved to the C-shaped connecting clamp (24), the bayonet of the C-shaped connecting clamp (24) is closed by operating the electric controloil cylinder (16), and the inner ring leading-out wire bending wire head (12) and the outer ring leading-out wire bending wire head (13) are kneaded together. And conditions are provided for production automation.

Owner:SHANXI FENXI HEAVY IND

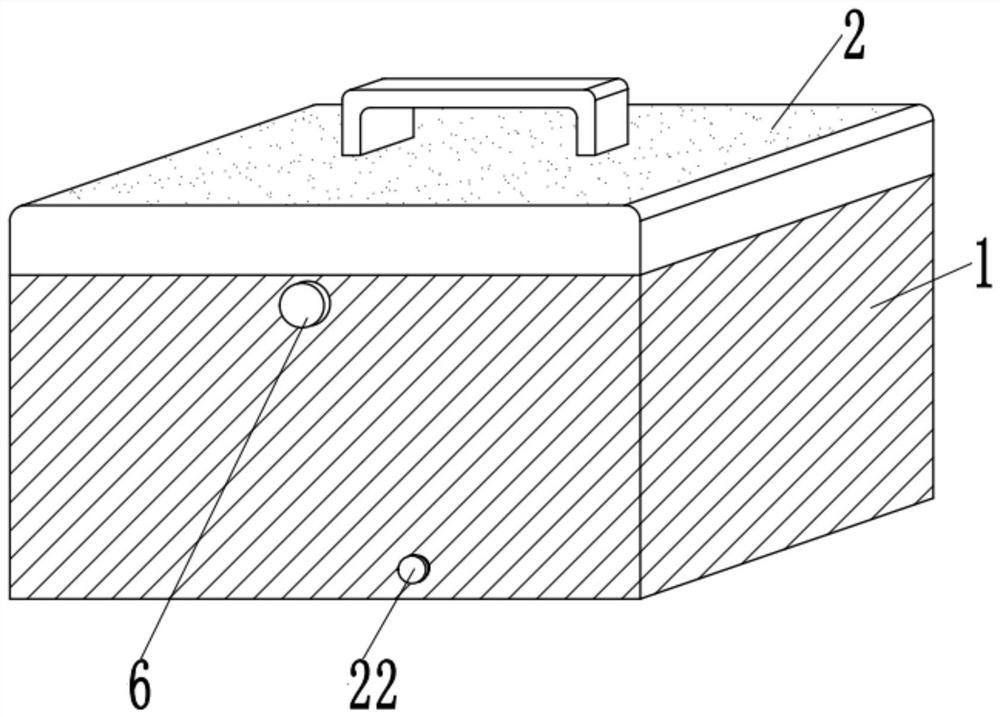

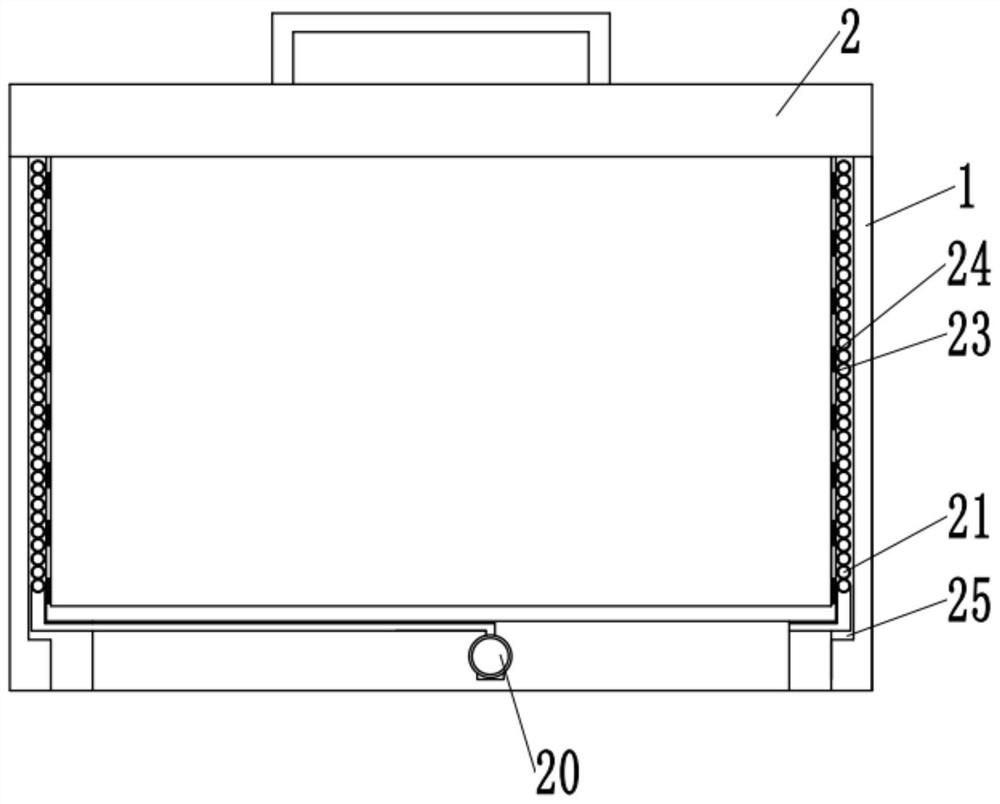

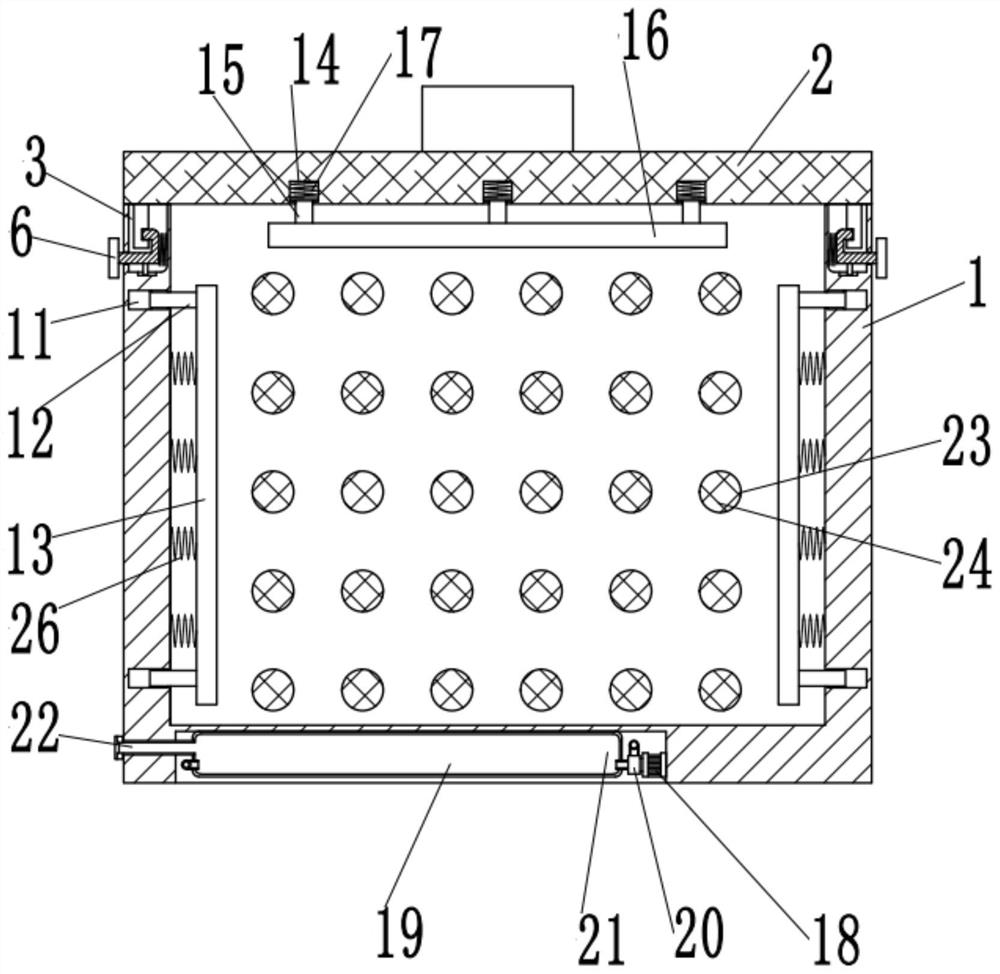

Feeding device for hot pressing die

The invention discloses a feeding device for a hot pressing die. The feeding device comprises a base, a lower die is installed in the center of the top of the base, an upper die is arranged over the lower die, a lifting positioning mechanism is installed on the upper side of the periphery of the lower die, supporting guide rails are arranged on the two sides of the base respectively, and a feeding mechanism and a discharging mechanism are installed on the other two sides of the base respectively. The feeding mechanism and the discharging mechanism are installed at the two ends of the two supporting guide rails correspondingly, the lifting positioning mechanism comprises a lower frame, the lower die is sleeved with the lower frame in a sliding mode, and it is guaranteed that the lower frame and an upper frame are vertically lifted through sliding connection of a limiting sliding rod and a limiting barrel; and the lifting speed of an air cylinder is controlled through friction between friction plates and friction between a supporting plate and the friction plates, and the situation that the lifting speed of the air cylinder is too high when the lower frame is lifted is prevented.

Owner:ANHUI JINCEN COMPOSITES

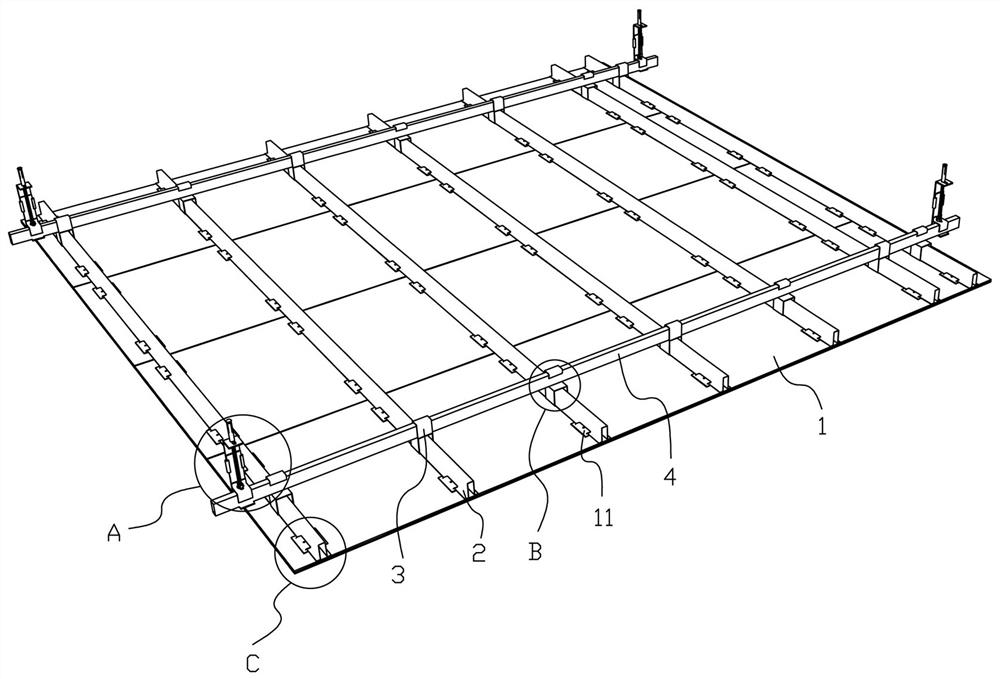

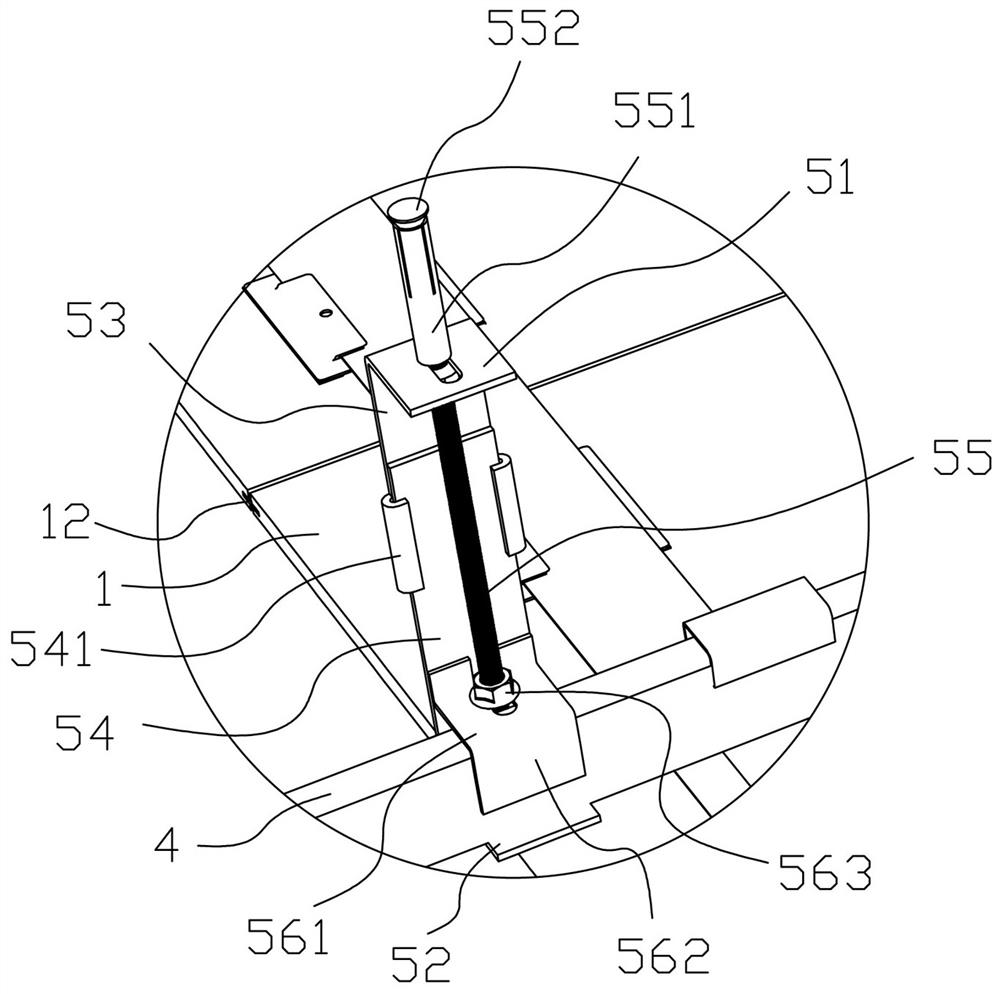

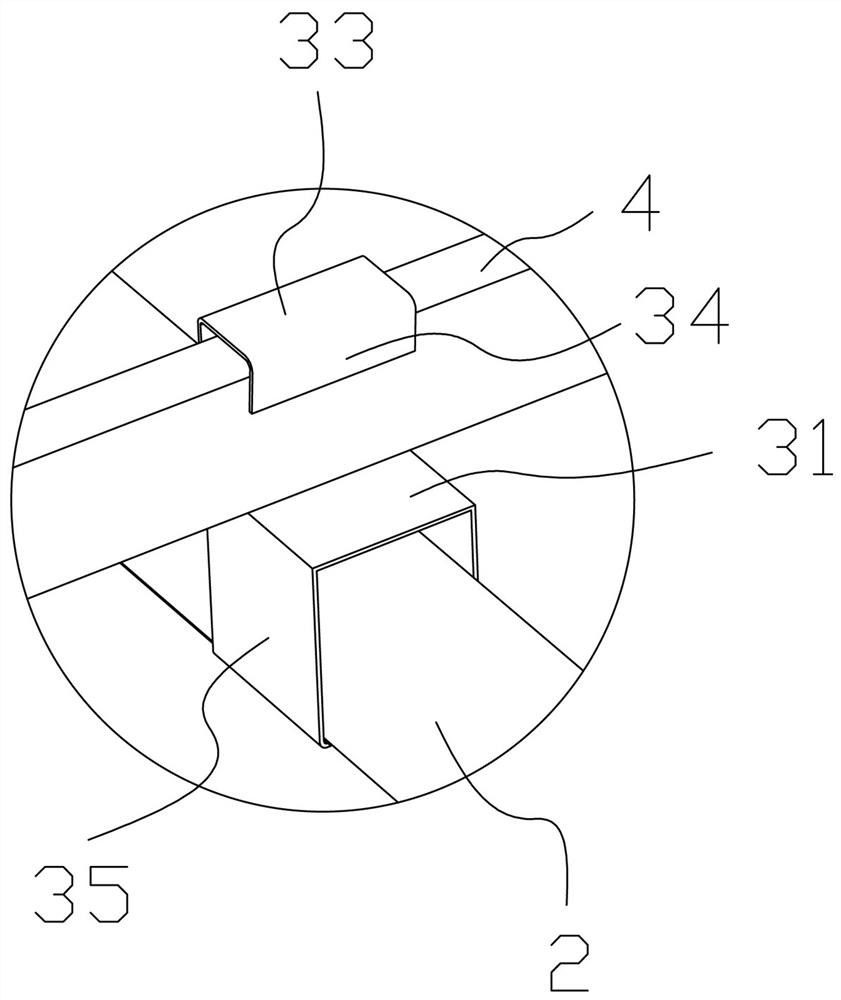

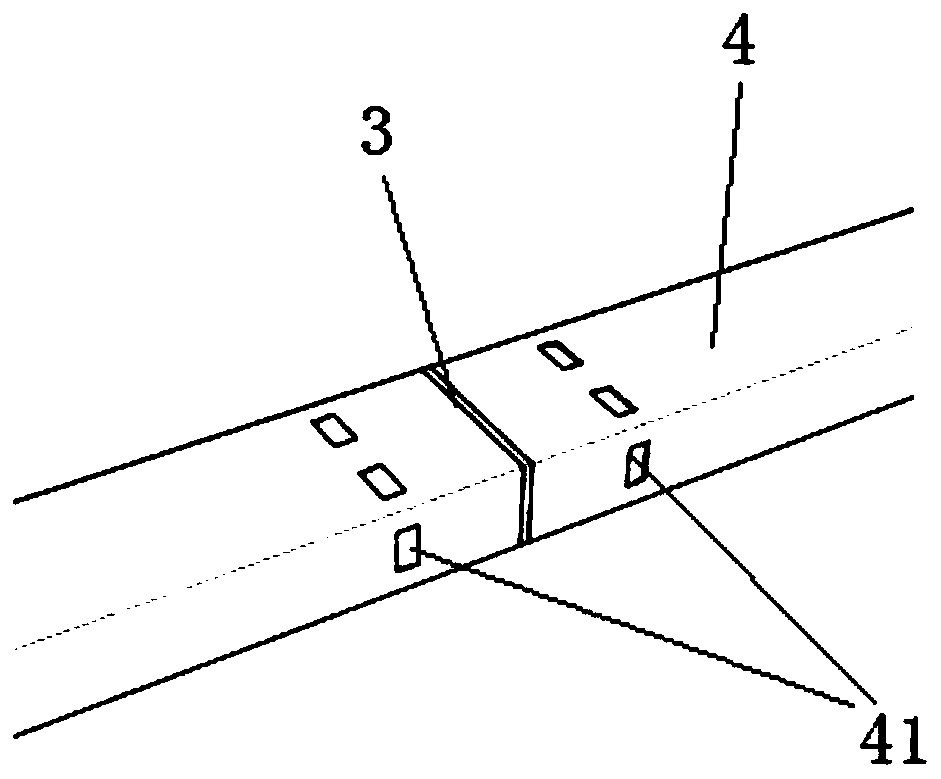

Ceiling structure suitable for square steel keel and mounting method thereof

PendingCN112814255AImprove versatilityEasy to disassembleCeilingsCeiling mountManufacturing engineering

The invention provides a ceiling structure suitable for a square steel keel and a mounting method thereof, and belongs to the technical field of ceiling mounting. The ceiling structure suitable for the square steel keel comprises a plurality of veneers, a plurality of bases, the keel, hanging pieces and telescopic hanging pieces. According to the ceiling structure suitable for the square steel keel and the mounting method thereof, the telescopic hanging pieces are clamped in first clamping grooves formed by first clamping structures, the other end of the bottom of the keel is clamped in second clamping grooves formed by second clamping structures, thus the telescopic hanging pieces and the keel are connected in a fastened mode through the hanging pieces, and the universality is greatly improved; the plurality of veneers are spliced, meanwhile, one end of the bottom of the keel is connected to the bases on the multiple veneers, thus the veneers are connected to the bottom ends of the hanging pieces in a fastened mode, the length of the telescopic hanging pieces is adjusted, the veneers are lifted overall, and mounting of a whole ceiling is completed; and dismounting is easy, adjusting and replacing are convenient, and the dismounting cost is reduced.

Owner:ZHEJIANG YASHA DECORATION

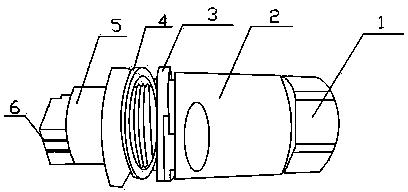

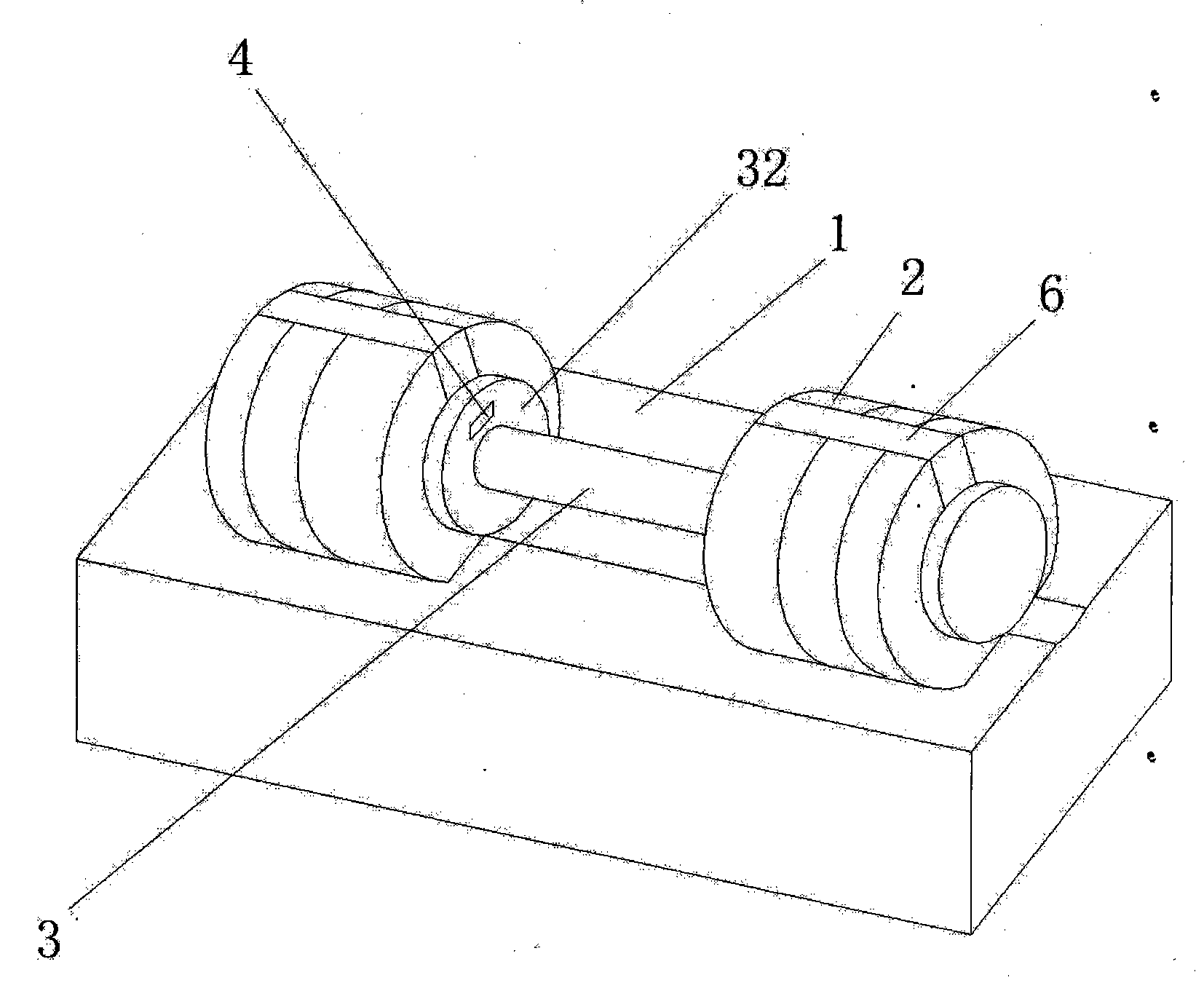

Anti-seismic multi-bayonet connecting device

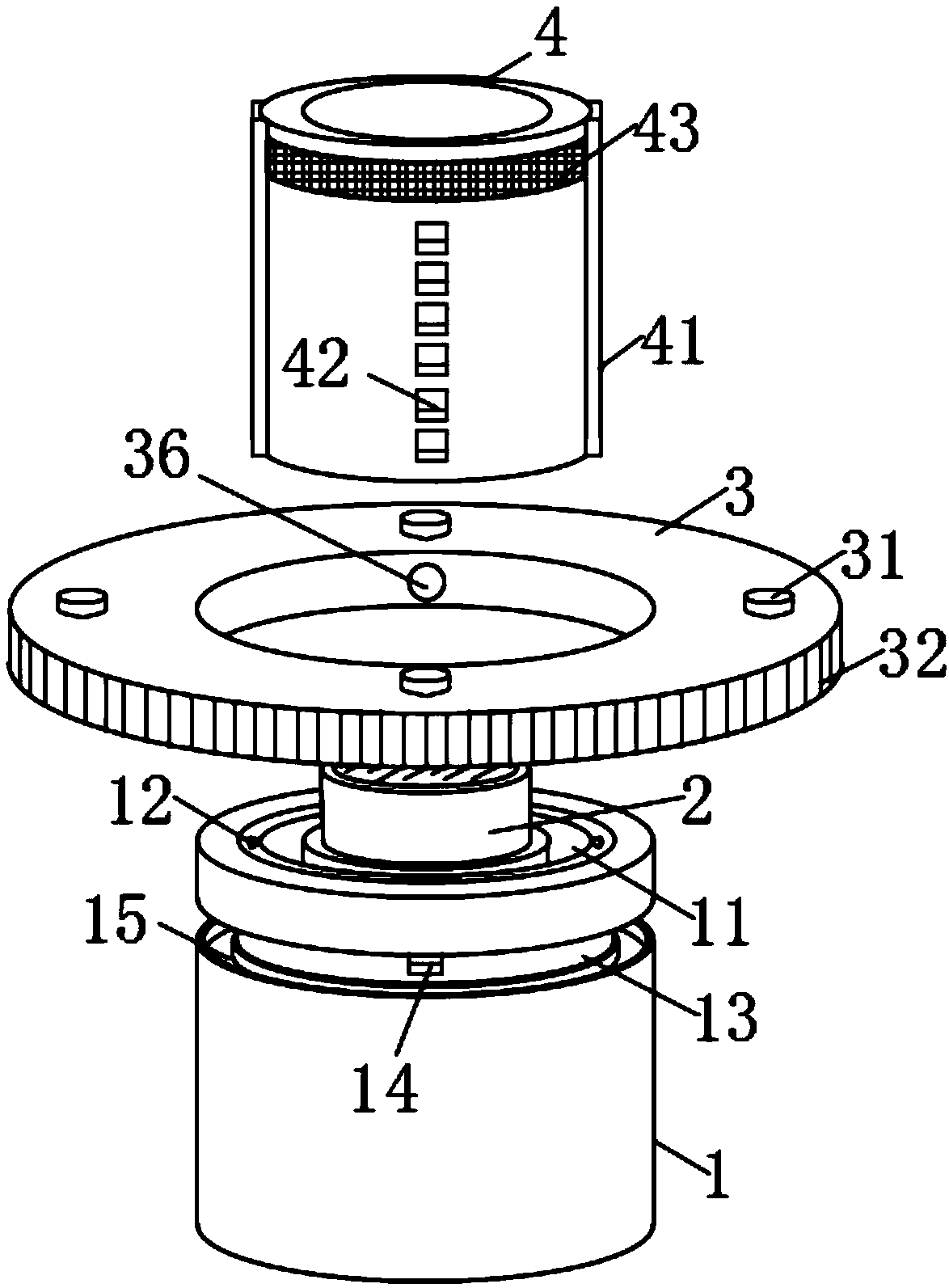

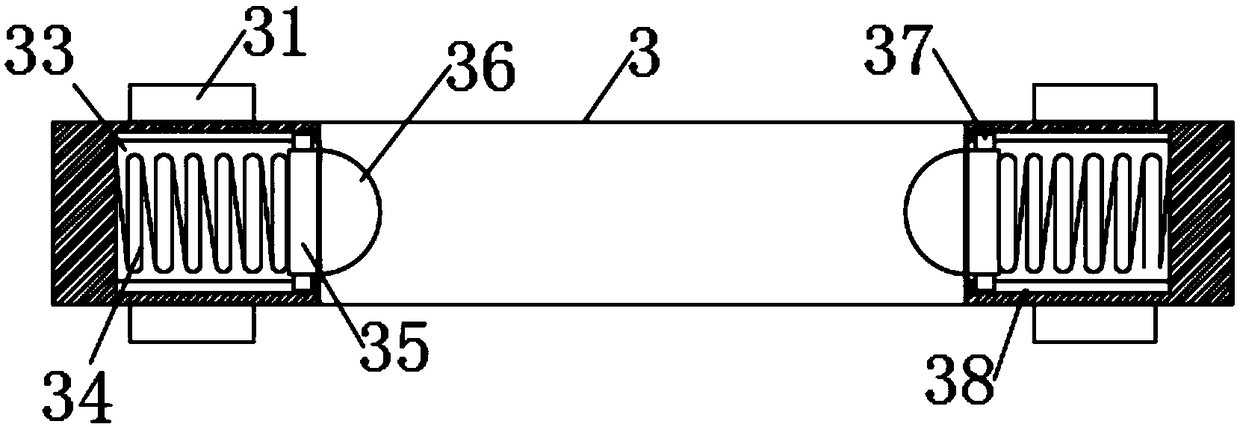

InactiveCN103682802AWith anti-seismic effectFirmly connectedCoupling device detailsRubber ringEngineering

The invention discloses an anti-seismic multi-bayonet connecting device which comprises a rotary head (1), a connecting body (2), a rubber ring (4), a connecting head (5) and a plurality of bayonets (6). The rotary head (1) and the connecting head (5) are respectively connected to two ends of the connecting body (2), a buffer component (3) is arranged at a joint end of the connecting body (2) and the connecting head (5), a retainer ring is arranged at a joint end of the connecting head (5) and the connecting body (2), the rubber ring (4) is arranged between the retainer ring and the buffer component (3), and the connecting head (5) is connected with the connecting body (2) in a threaded manner; the multiple bayonets (6) are formed in the connecting head (5). The anti-seismic multi-bayonet connecting device with the structure has the advantages that the anti-seismic multi-bayonet connecting device can be used for clamping conveniently, an anti-seismic effect can be realized by the anti-seismic multi-bayonet connecting device which is a connector, and the anti-seismic multi-bayonet connecting device is suitable to be used in fields.

Owner:CHENGDU GKHB INFORMATION TECH

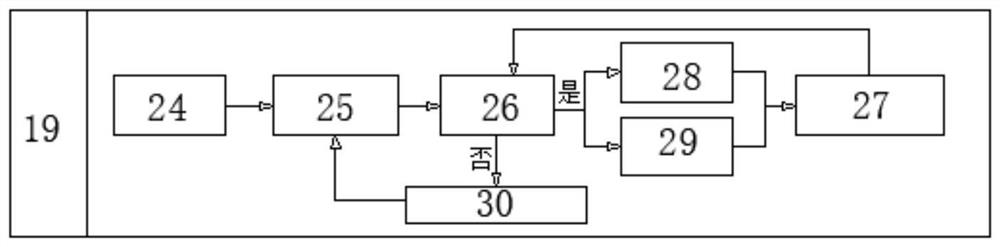

Monitoring system used for in-place jacking of tower crane and tower crane

The embodiment of the invention provides a monitoring system used for in-place jacking of a tower crane and the tower crane and belongs to the technical field of crane control. The tower crane comprises hanging shoes, hanging plates and steps. When the tower crane is jacked in place, the hanging shoes are connected with the hanging plates in a clamping manner. The monitoring system comprises distance sensors which are arranged on the hanging shoes / hanging plates and are used for detecting the distances between the distance sensors and the clamping connection positions of the hanging shoes / hanging plates and the steps. By means of the above technical scheme, whether the hanging shoes / or the hanging plates are accurately connected with the steps of standard joints in a clamping manner or notcan be accurately detected, and whether the tower crane is jacked in place or not can be monitored in real time.

Owner:ZOOMLION HEAVY IND CO LTD +1

Adjustable dumbbell with monitoring function

The invention relates to a dumbbell, in particular to an adjustable dumbbell with the monitoring function. Balance weight cavities are formed in a balance weight base, balance weight plates are clamped in the balance weight cavities and are detachably arranged on balance weight mechanisms, openings are formed in the top ends of the balance weight plates, a clamping hole is formed in the inner wall of each opening, a clamping groove is formed in the bottom of each balance weight plate, convex sheets are arranged in the balance weight cavities and are clamped to the clamping grooves, a handle is detachably connected with the balance weight base, and a monitoring device is further arranged on the handle. According to the structure, because the dumbbell is provided with the monitoring device, and the handle is detachably connected with the balance weight base, when the dumbbell is in use, the balance weight base can be used as weight balancing and can also serve as part of the weight, various weight balancing schemes are provided, and the dumbbell can be integrally carried and is very convenient to use; the balance weight plates are clamped to the clamping holes through the convex sheets, no noise is generated, resistance is small, connection is firm, the dumbbell will not waggle, a user can operate the dumbbell with one single hand very conveniently, and the overall structure is compact.

Owner:马润华

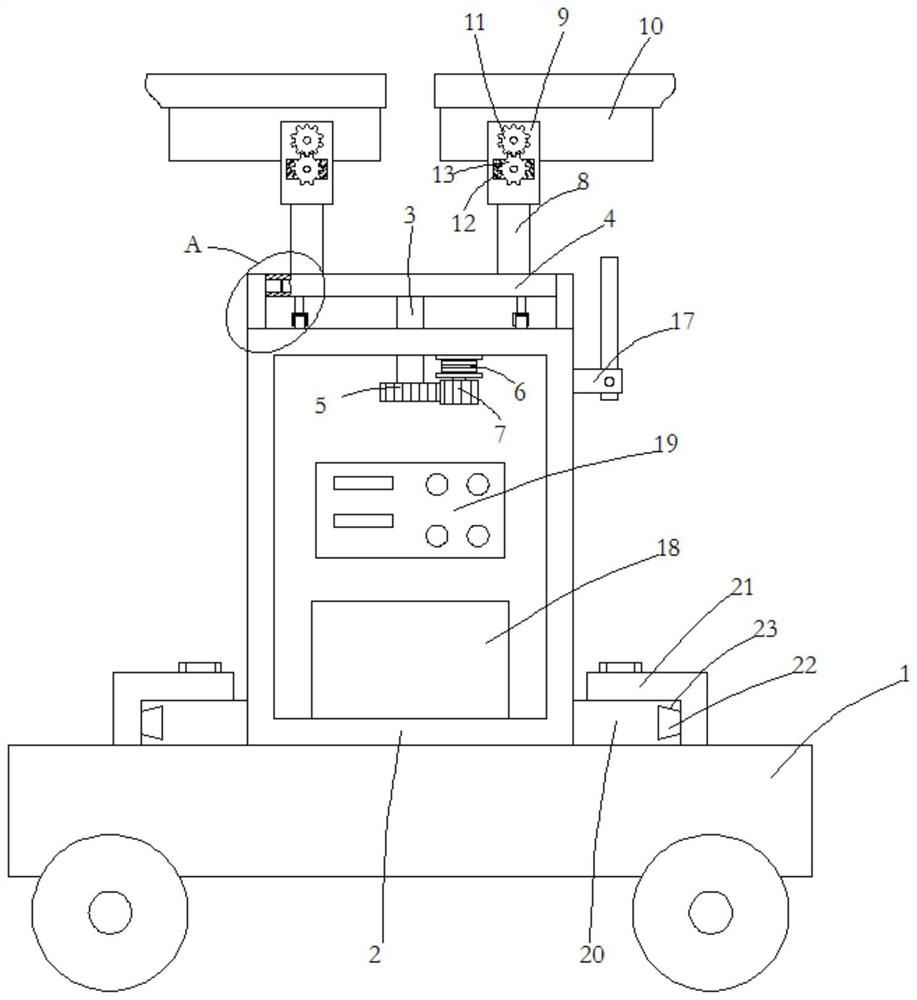

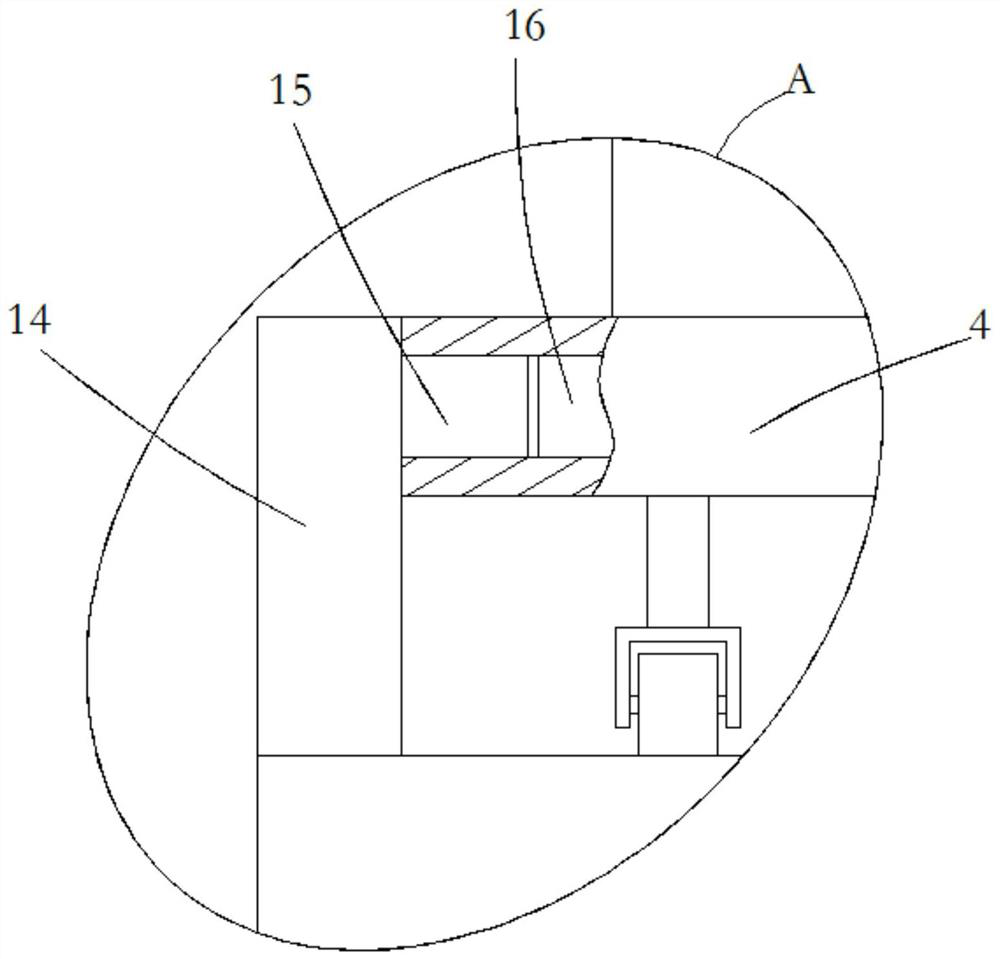

Real-time pedestrian volume monitoring equipment and equipment operation method

PendingCN112040178AAdjust the relative monitoring positionIncreased relative monitoring rangeCharacter and pattern recognitionClosed circuit television systemsBall bearingGear wheel

The invention relates to the technical field of mobile monitoring equipment, and discloses real-time pedestrian volume monitoring equipment and an equipment operation method. The real-time pedestrianvolume monitoring equipment comprises a mobile trolley, a fixed box is fixedly clamped to the upper end of the mobile trolley, a through hole is formed in the upper end of the fixed box, and a rotating rod is rotatably sleeved with the through hole through a ball bearing, and a rotating plate is fixedly connected to the upper end of the rotating rod, a first driven gear is fixedly connected to thelower end of the rotating rod, a driving motor is fixedly connected to the inner wall of the top of the fixed box, and a first driving gear engaged with the first driven gear is fixedly connected toan output shaft of the driving motor. According to the invention, the monitoring direction of a monitoring camera can be rapidly adjusted, the monitoring range of the monitoring camera is improved, and an Internet of Things wireless communication module is also arranged, so that the actual detection condition can be transmitted to a mobile phone mobile terminal.

Owner:GUILIN UNIV OF ELECTRONIC TECH

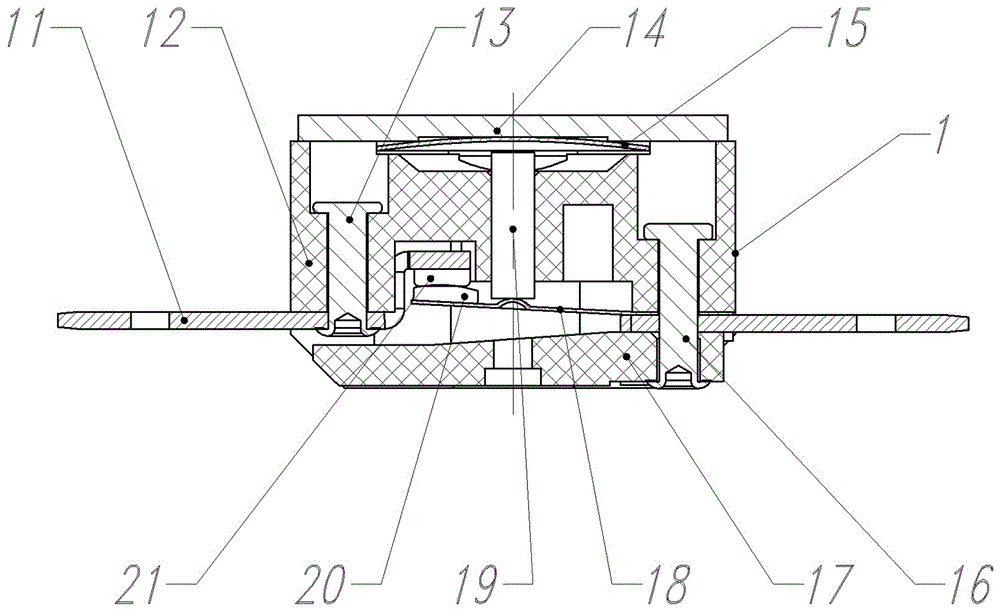

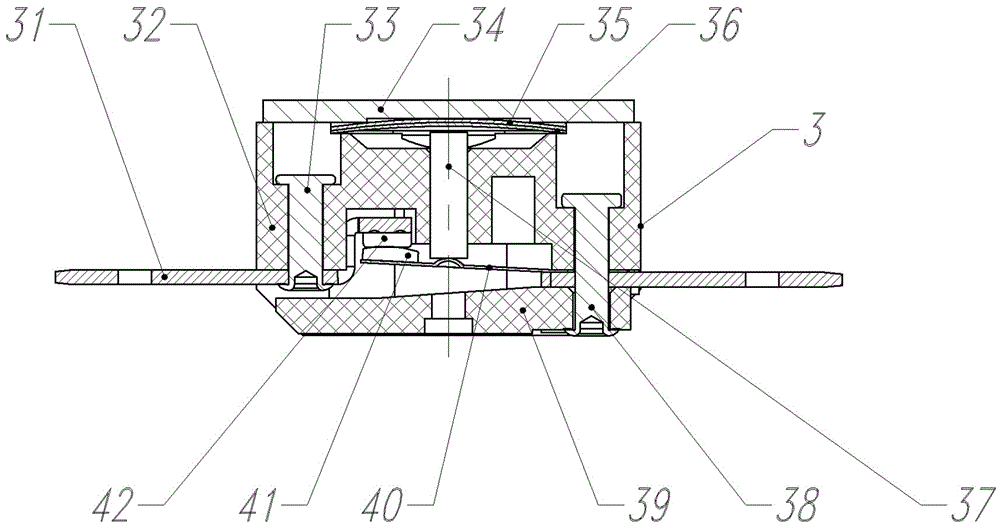

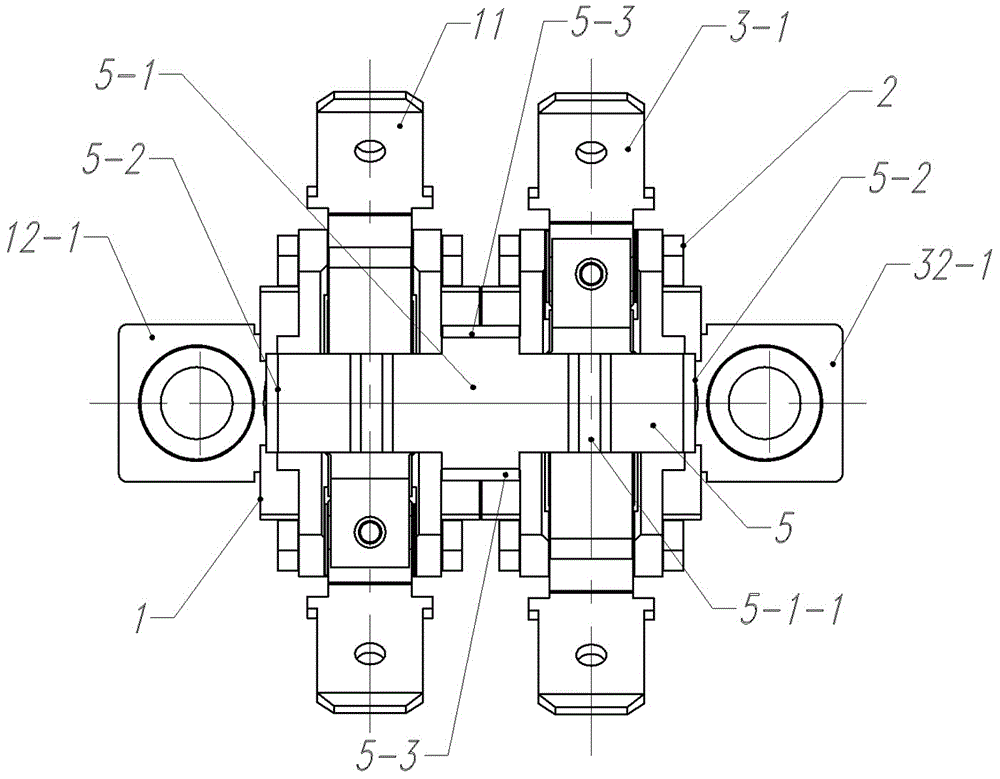

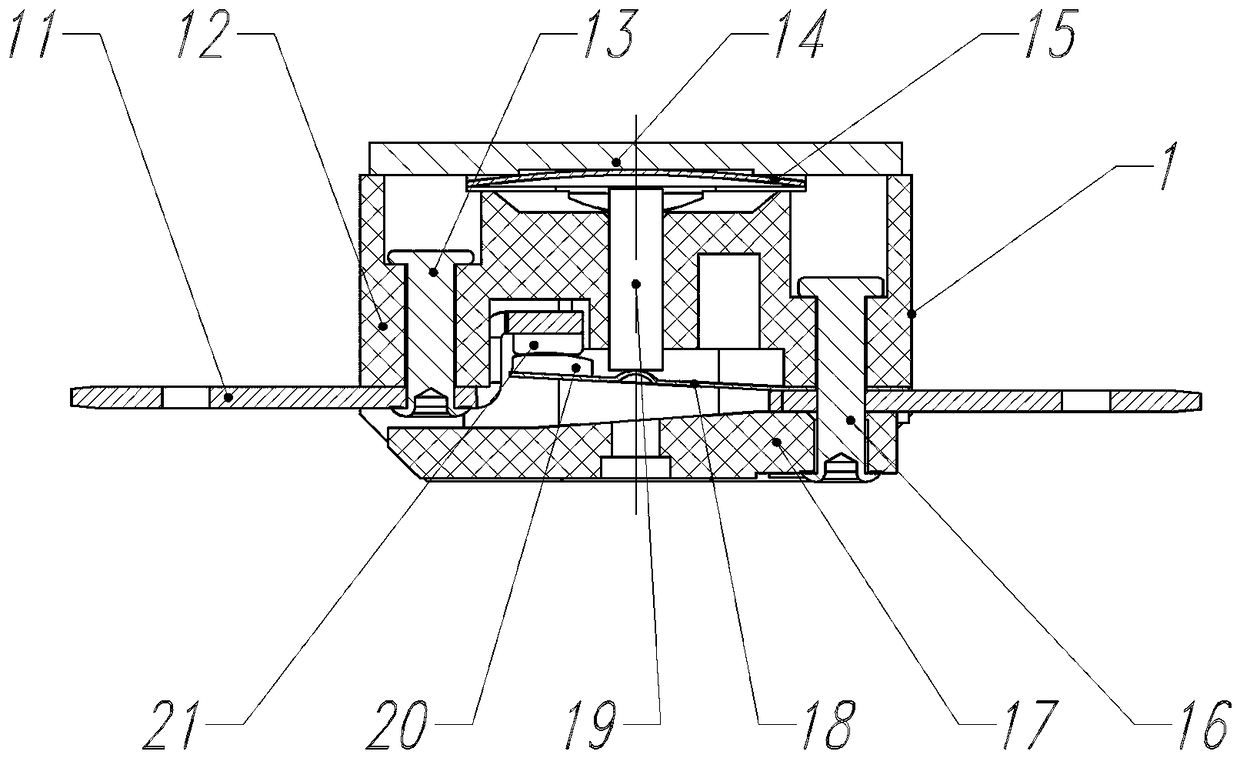

Snap-action thermostat with duplex structure

ActiveCN106298362ASimple structureEasy to assembleThermal switch detailsTemperature controlThermostat

A snap-action thermostat with a duplex structure comprises a temperature controlled snap-action thermostat, a over-temperature-protection snap-action thermostat and a stainless steel elastic retaining clip. The two snap-action thermostats are provided with unilateral installation baseboards; a batten for the stainless steel elastic retaining clip, a left side jaw and a right side jaw, a front side locating plate and a rear side locating plate are elastically connected with the outer side surfaces of the shells of the snap-action thermostats in a clamped mode. It is ensured that each metal cover of the snap-action thermostats is closely attached to the temperature sensing face of a electric heating appliance which is matched with the snap-action thermostats. Compared with a single installation, the duplex structure enables the mounting position size and spatial volume of the snap-action thermostats to be reduced by 50%, the rate of finished products can achieve 100%, and production cost will be greatly reduced.

Owner:佛山市通宝华龙控制器有限公司

Battery installation structure of somatosensory balance car

ActiveCN108974221BGuaranteed firmnessEasy to useCell component detailsCycle batteriesElectrical batteryStructural engineering

Owner:嘉兴众衡电气科技有限公司

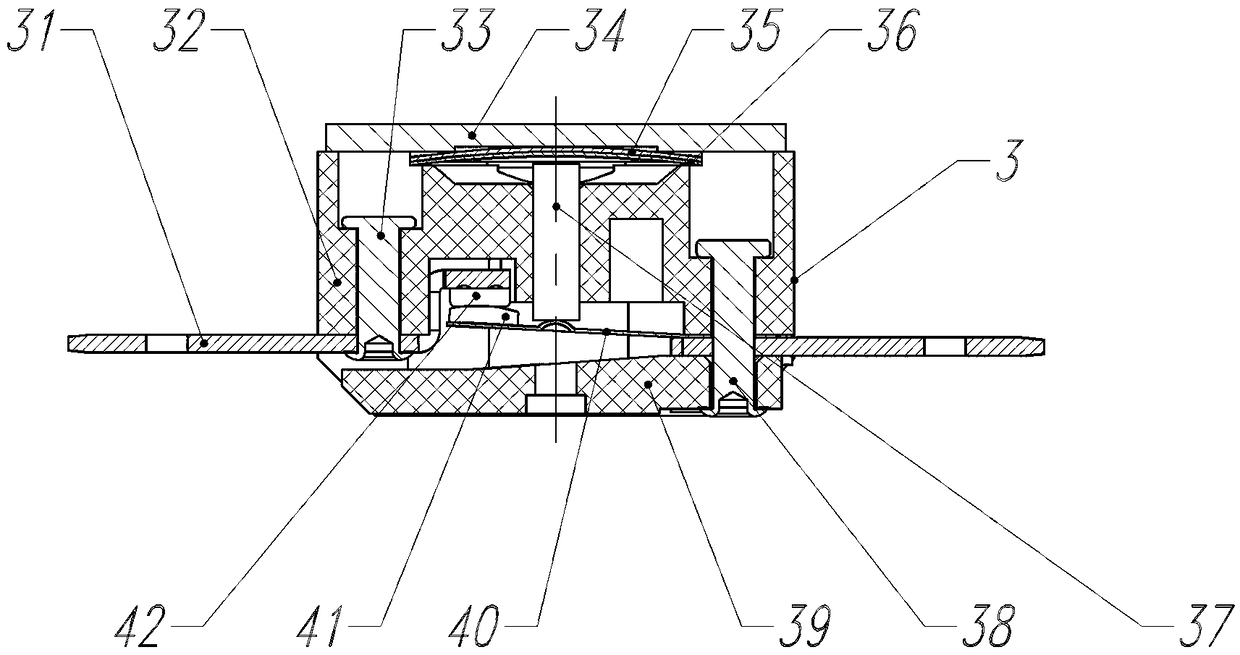

Automatic side wall separating mechanism of electric connector

ActiveCN109764767AQuick lockEasy to useVehicular energy storageSelf-propelled projectilesEngineeringMechanical engineering

The invention relates to an automatic side wall separating mechanism of an electric connector. The side wall automatic separating mechanism comprises a plug and a socket, wherein the socket comprisesa socket shell and a locking pin, and the plug comprises an outer shell, a plug cable cover, a fixing frame and a plug shell; the plug cable cover is fixedly connected in the fixing frame, and a clamping hook matched with the locking pin is arranged on the outer shell. The automatic side wall separating mechanism of the electric connector is characterized in that the clamping hook is arranged on the outer shell and the locking pin is arranged on the socket, when the plug and the socket can be plugged, only the downward insertion force needs to be applied to the outer shell, when the plug is incontact with the socket, a locking block is subjected to upward pressure, a pressure spring is compressed, when a groove is matched with a moving end, a guide rod moves leftwards under the acting force of a spring, the outer shell moves leftwards along with the guide rod, and when the clamping hook on the outer shell clamps the locking pin, the plug and the socket can be locked. The automatic side wall separating mechanism has the advantages of being capable of automatically separating along with elasticity, high in reliability and convenient to use.

Owner:杭州航天电子技术有限公司

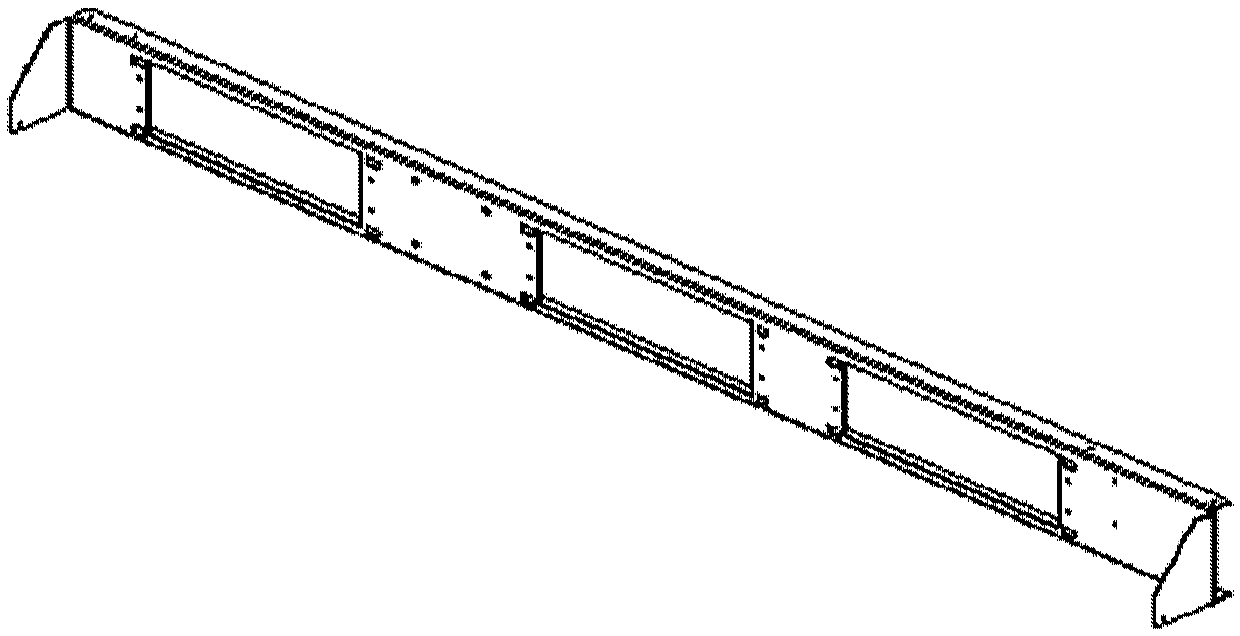

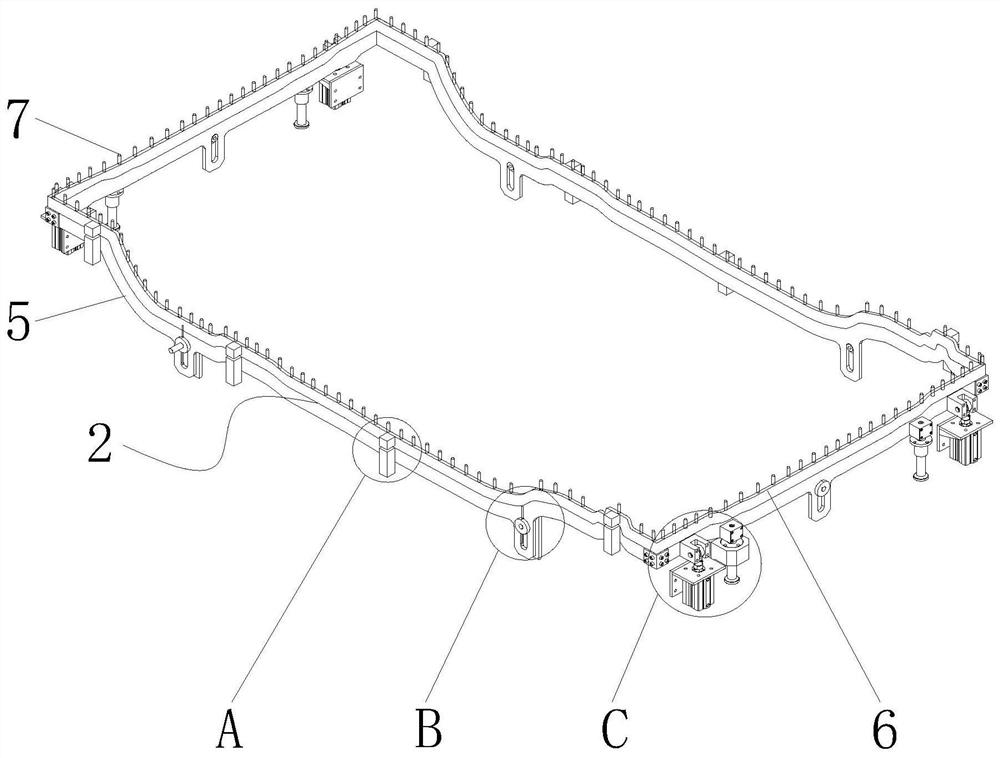

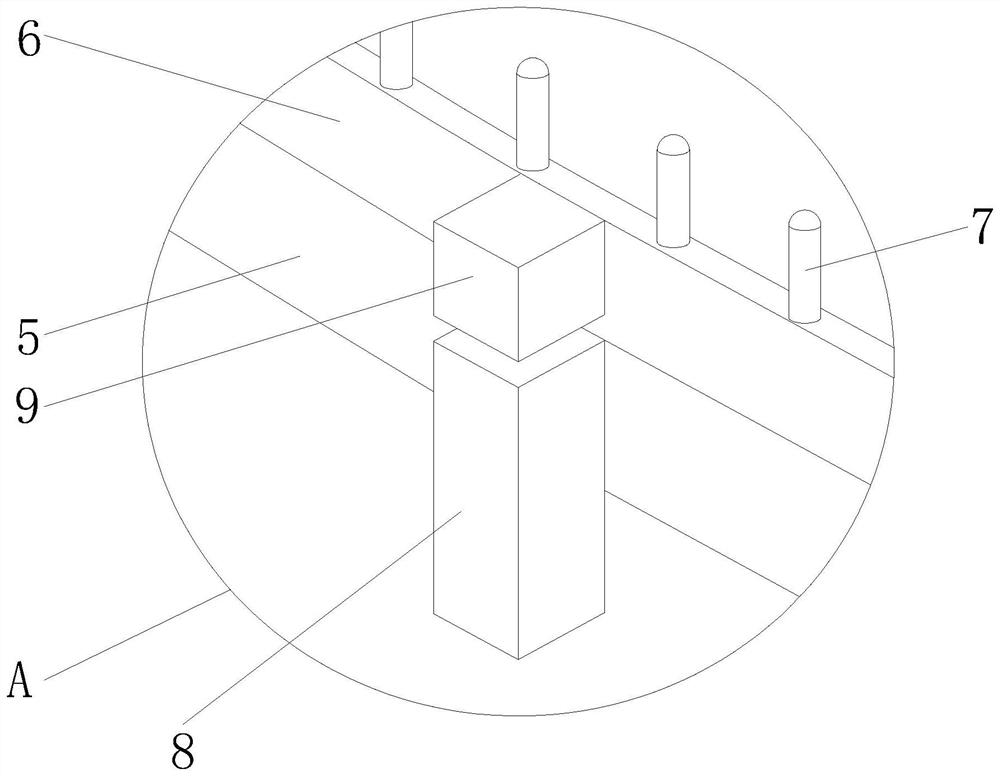

Semi-automatic equipment integrating punching and assembling of car roof decorative strip

ActiveCN111775459ARealize integrationImprove work efficiencyDomestic articlesMotor vehicle partSemi automatic

The invention provides semi-automatic equipment integrating punching and assembling of a car roof decorative strip, and belongs to the technical field of assembly of automobile parts. The semi-automatic equipment comprises a rack, a plurality of supporting tables, a plurality of positioning modules, a plurality of punching modules, two rivet pressing modules and a plurality of pressing modules; anoperation platform is arranged on the rack; the plurality of supporting tables are arranged in the length direction of the operation platform; the plurality of positioning modules are arranged in thelength direction of the operation platform; the plurality of punching modules are arranged in the length direction of the operation platform; the two rivet pressing modules are installed at the two ends of the operation platform correspondingly, each rivet pressing module comprises a rivet pressing base and a rivet pressing structure, an abutting part is installed on one rivet pressing structure,and a pressing part is installed on the other rivet pressing structure; and the plurality of pressing modules are arranged in the length direction of the operation platform. According to the semi-automatic equipment integrating punching and assembling of the car roof decorative strip, integration of punching and assembling of the car roof decorative strip is achieved, and then the working efficiency and the product qualification rate are improved.

Owner:宁波蓝圣智能科技有限公司

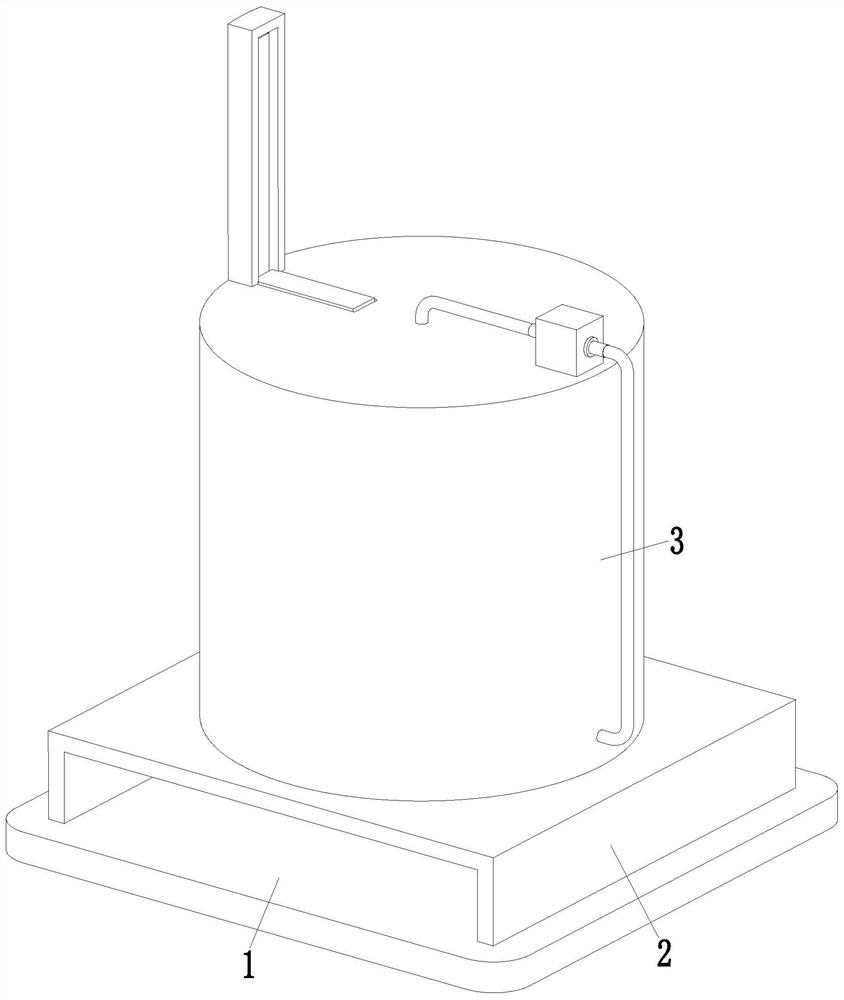

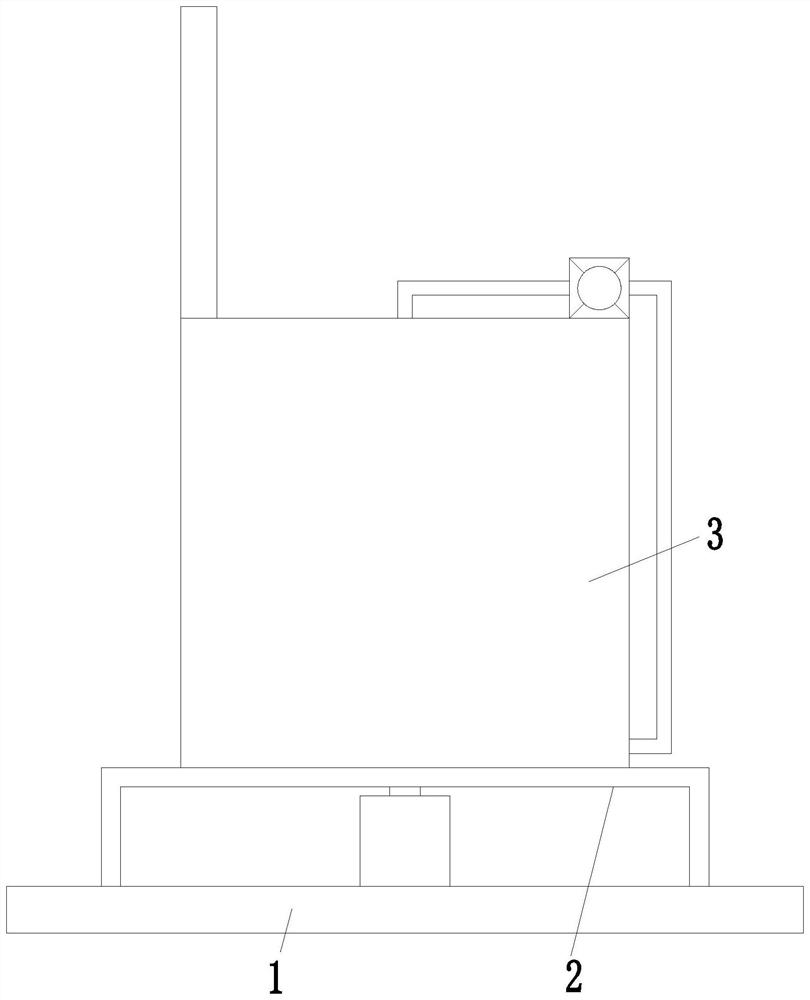

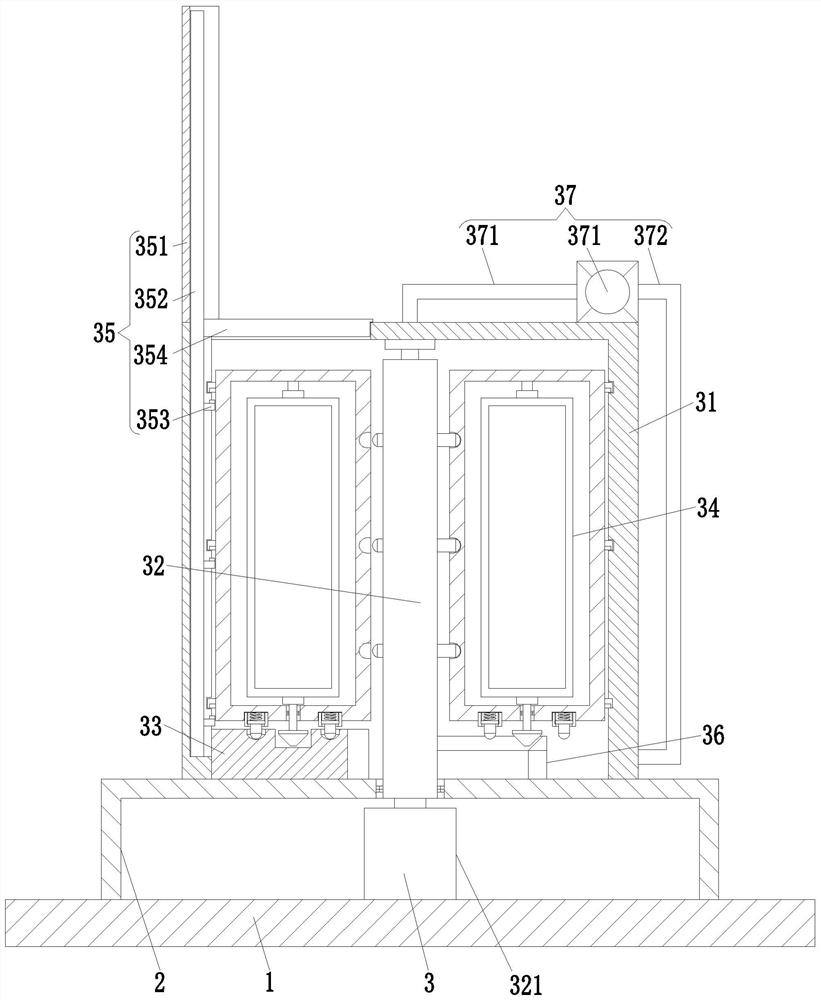

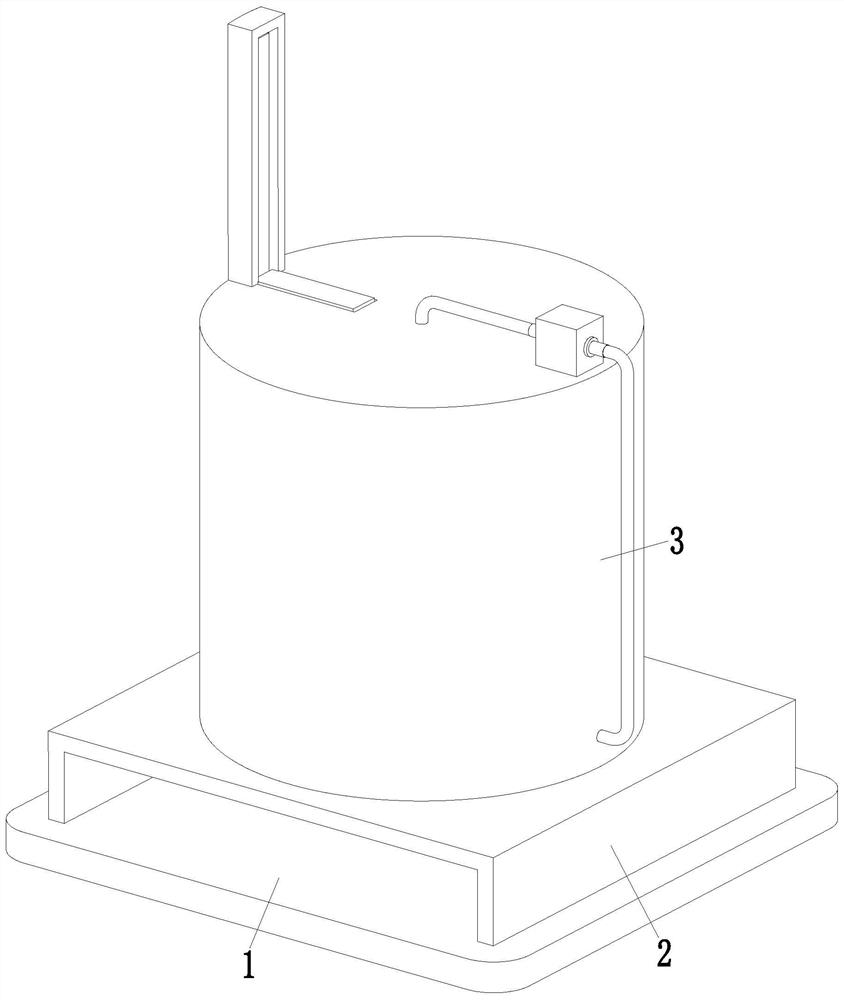

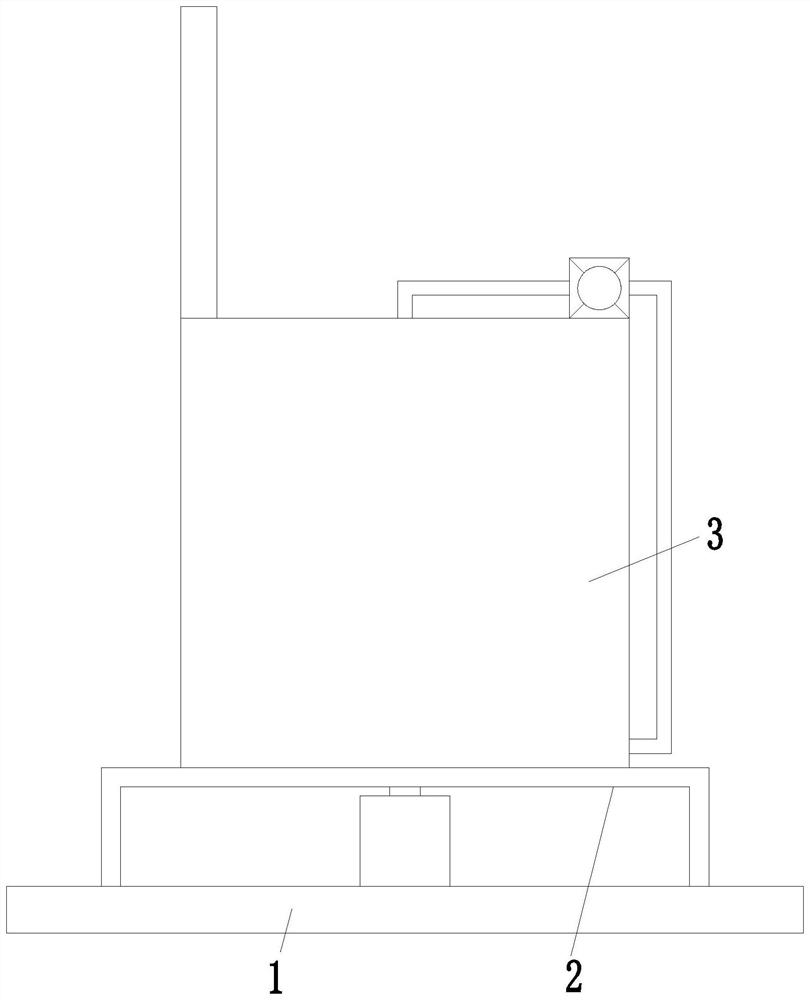

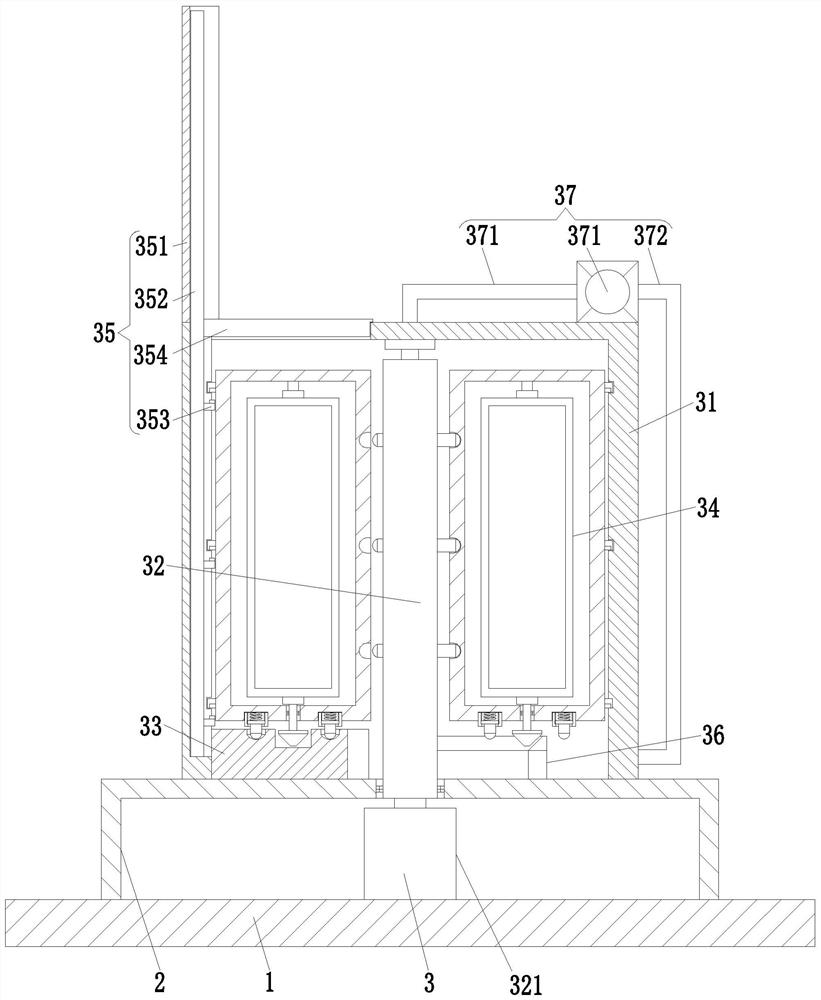

Steel-wood fireproof door flame-retardant material drying equipment

ActiveCN113847796AAvoid accumulationGuaranteed drynessDrying solid materials without heatDrying gas arrangementsWater vaporDry box

The invention relates to steel-wood fireproof door flame-retardant material drying equipment comprising a bottom plate frame, a supporting frame and a drying assembly, the supporting frame is installed at the upper end of the bottom plate frame, the section of the supporting frame is of a U-shaped structure, and the drying assembly is installed in the middle of the upper end of the supporting frame. The problems that when existing equipment is used for drying flame-retardant core board materials, core boards are usually directly placed in a drying box to be dried, the processing effect is poor, a large amount of water vapor is prone to being accumulated due to the loose and porous structures in the flame-retardant core boards, the water vapor cannot be effectively removed, processed fireproof doors are liable to deform due to damp, when the existing equipment dries the flame-retardant core boards, the flame-retardant core boards are usually stacked together, the flame-retardant core boards cannot be dried one by one, and the drying effect of the flame-retardant core boards is affected can be solved.

Owner:安徽双盾消防科技有限公司

Special harmonic filter for rail transit

InactiveCN110831375AMaximize splitAvoid demolitionCasings/cabinets/drawers detailsSlide plateRail transit

The invention discloses a special harmonic filter for rail transit. The special harmonic filter for rail transit comprises a shell, rectangular grooves are formed in the side walls of the two ends ofthe shell, the rectangular grooves are through grooves, and is internally movably provided with mounting plates, each movably plate is internally provided with two mounting cavities, the inner walls of the two ends of the mounting cavity are fixedly connected with elastic pieces, the free ends of the elastic pieces are fixedly connected with sliding plates, positioning inserting plates are fixedlyarranged at one surfaces, back to the elastic pieces, of the sliding plates, penetrate the mounting cavities and are movably inserted with positioning slots arranged in the rectangular grooves, afterthe movable plates at the two sides of the shell are completely dismounted, and elements in the shell are maintained, so that the shell can be maximumlly dismounted, a top cover can be avoided to bedismounted to cause inconvenience of maintenance, the maintenance area is expanded, the maintenance is more thorough, subsequent installation is convenient, operation is easy and rapid, and starting is easy.

Owner:安徽博格韦尔电气股份有限公司

Connecting structure of fabricated square steel

PendingCN110847389AGuaranteed to be moreGuaranteed multi-faceted snap-inBuilding constructionsClassical mechanicsEngineering

The invention provides a connecting structure of fabricated square steel. The connecting structure comprises a connecting part and square steel, wherein the connecting part comprises a connecting pipe, connecting claws and a limiting strip, the connecting claws and the limiting strip are correspondingly arranged on the outer wall of the connecting pipe; in the length direction, the limiting stripis located in the middle of the connecting pipe; the connecting claws are symmetrically arranged on the two sides of the limiting strip, and the connecting claws are correspondingly arranged on four side walls of the connecting pipe; connecting holes are formed in the end parts of the square steel, and the positions of the connecting holes and the positions of the connecting claws are arranged correspondingly; and the square steel is symmetrically arranged on the two sides of the connecting part, and the connecting holes are connected with the connecting claws in a clamped mode. Compared withthe prior art, the connecting structure has the following advantages that the mechanical connection between the square steel is achieved through the connecting part, fast installation is achieved, meanwhile the connection is reliable, the installation effect is improved, and the construction cost is lowered.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

A sudden jump thermostat with double structure

ActiveCN106298362BSimple structureEasy to assembleThermal switch detailsTemperature controlEngineering

A snap-action thermostat with a duplex structure comprises a temperature controlled snap-action thermostat, a over-temperature-protection snap-action thermostat and a stainless steel elastic retaining clip. The two snap-action thermostats are provided with unilateral installation baseboards; a batten for the stainless steel elastic retaining clip, a left side jaw and a right side jaw, a front side locating plate and a rear side locating plate are elastically connected with the outer side surfaces of the shells of the snap-action thermostats in a clamped mode. It is ensured that each metal cover of the snap-action thermostats is closely attached to the temperature sensing face of a electric heating appliance which is matched with the snap-action thermostats. Compared with a single installation, the duplex structure enables the mounting position size and spatial volume of the snap-action thermostats to be reduced by 50%, the rate of finished products can achieve 100%, and production cost will be greatly reduced.

Owner:佛山市通宝华龙控制器有限公司

Battery mounting structure of somatosensory balance vehicle

Owner:嘉兴众衡电气科技有限公司

Unmanned aerial vehicle guide rope throwing system and using method thereof

ActiveCN111463705ARealize transportationSolve the problem of positioning whereaboutsFilament handlingApparatus for overhead lines/cablesUncrewed vehicleElectric machinery

The invention provides an unmanned aerial vehicle guide rope throwing system and a using method thereof, and relates to the technical field of power transmission line operation. By setting an unmannedaerial vehicle, a rope throwing bridge is positioned below the unmanned aerial vehicle and a guide rope is positioned and clamped on the rope throwing bridge; the rope throwing bridge comprises a support, a normally-closed clamp body and a remote control loosening and clamping motor. A clamping piece on one side of the normally-closed clamp body is fixedly arranged on the support; the remote control loosening and clamping motor is connected with the pressing end of the free clamping piece on the other side of the normally-closed clamp body through a pull rope to adjust the opening amplitude of a clamping opening of the normally-closed clamp body, so clamping and loosening of the guide rope are achieved; and the guide rope on the rope throwing bridge frame is driven by the unmanned aerialvehicle to realize high-altitude positioning, loosening and downward throwing of the guide rope. The guide rope is clamped on the rope throwing bridge frame, high-altitude positioning, loosening and downward throwing of the guide rope are achieved through driving of the unmanned aerial vehicle, transportation of the guide rope is achieved, and a new thought is provided for high-altitude rope throwing.

Owner:STATE GRID ANHUI ELECTRIC POWER CO LTD ANQING POWER SUPPLY CO +1

A kind of drying equipment for flame retardant materials of steel and wood fire doors

ActiveCN113847796BAvoid accumulationGuaranteed drynessDrying solid materials without heatDrying gas arrangementsWater vaporDry box

The invention relates to a drying equipment for flame-retardant materials for steel-wood fire doors, which includes a base frame, a support frame and a drying assembly. A support frame is installed on the upper end of the base frame. A drying unit is installed. The invention can solve the problem that when the existing equipment is drying the flame-retardant core board material, the core board is usually directly placed in the drying box for drying processing, the processing effect is poor, and the loose and porous structure inside the flame-retardant core board is easy to accumulate. A large amount of water vapor cannot effectively remove the water vapor, which will easily cause the processed fire door to be deformed due to moisture. Moreover, when the existing equipment is drying the flame-retardant core board, the flame-retardant core board is usually piled up. It is impossible to dry the flame-retardant core board one by one, which affects the drying effect of the flame-retardant core board and other problems.

Owner:安徽双盾消防科技有限公司

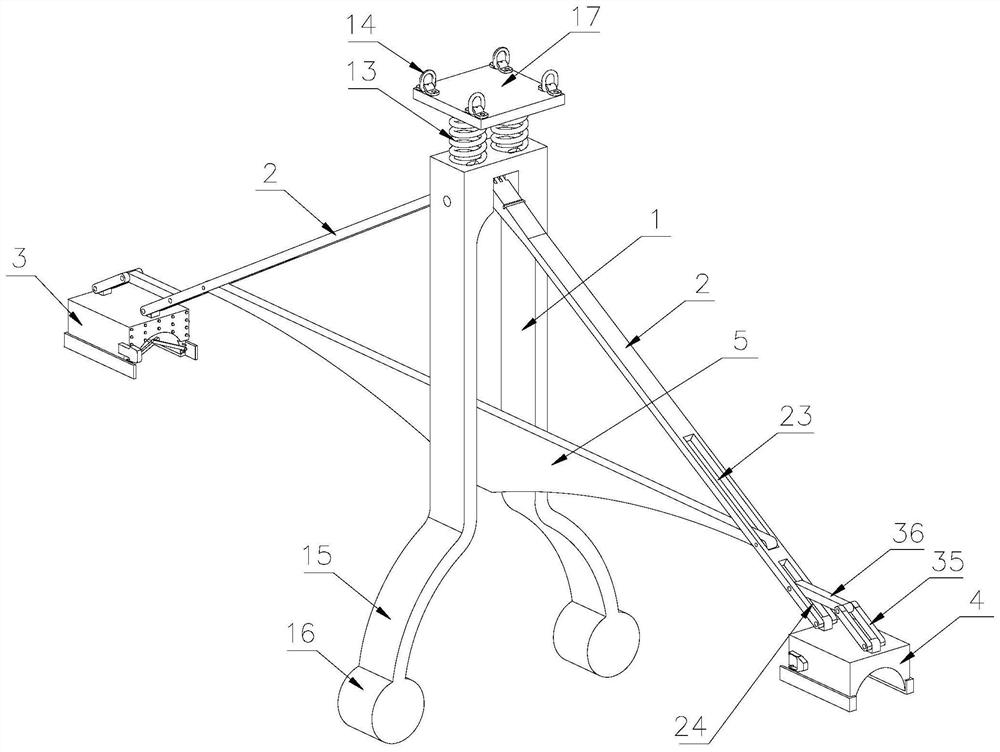

A portable auxiliary protection system for gymnastics training

ActiveCN113730895BAccurate dataApplicable to different application scenariosSport apparatusComplex mathematical operationsSimulationPhysical therapy

The invention provides a movable auxiliary protection system for gymnastics training, which includes a protection device, an inflation device, a collection device, an adjustment device, a lifting device and a processor. The protection device is used to protect the training position of the trainer, so as to realize Protection of the trainer; the collection device is used to collect the trainer, and if there is a danger or abnormal situation, an early warning signal will be triggered; the inflatable device will inflate the protection device based on the data collected by the collection device to protect the trainer; The lifting device is used to flexibly touch the height of the trainer's protection to protect the trainer's body from the impact of the protection device; the adjustment device adjusts the positions of the protection device and the lifting device based on the data of the acquisition device. The invention cooperates with the protection device and the inflatable device, so that the detection device can be adaptively adjusted according to different trainers during the detection process, so as to be suitable for different application scenarios.

Owner:曾烨琳

Printing packaging box with degradation function and production process thereof

InactiveCN113135338AWith degradation functionEasy to fixLiving organism packagingShock-sensitive articlesAdhesive beltStructural engineering

The invention relates to the technical field of packaging boxes, in particular to a printing packaging box with a degradation function, which comprises a box body, a clamping plate and a pressing plate. A top cover is clamped on the outer wall of the top of the box body, slots are formed in the two sides of the outer wall of the top of the box body, inserting blocks are welded to the two sides of the outer wall of the bottom of the top cover, and the inserting blocks are inserted into the slots. A clamping groove is formed in the outer wall of one side of each inserting block, a clamping block is slidably connected into each inserting groove and clamped into the corresponding clamping groove, buttons are welded to the ends, located outside the slots, of the clamping blocks, and fixing springs connected with the clamping blocks are welded to the inner walls of one sides of the slots. The printing packaging box with the degradation function has the beneficial effects that the clamping blocks can be clamped in the clamping grooves through the telescopic force of the fixing springs, the top cover can be conveniently fixed to the box body, meanwhile, the top cover can be conveniently opened, adhesive tape is not used for fixing, and repeated use can be achieved; and when the clamping blocks move, limiting blocks slide in limiting grooves, the clamping blocks can move in parallel, and the deflection phenomenon of the clamping blocks in the moving process is prevented.

Owner:滁州远达彩印包装有限公司

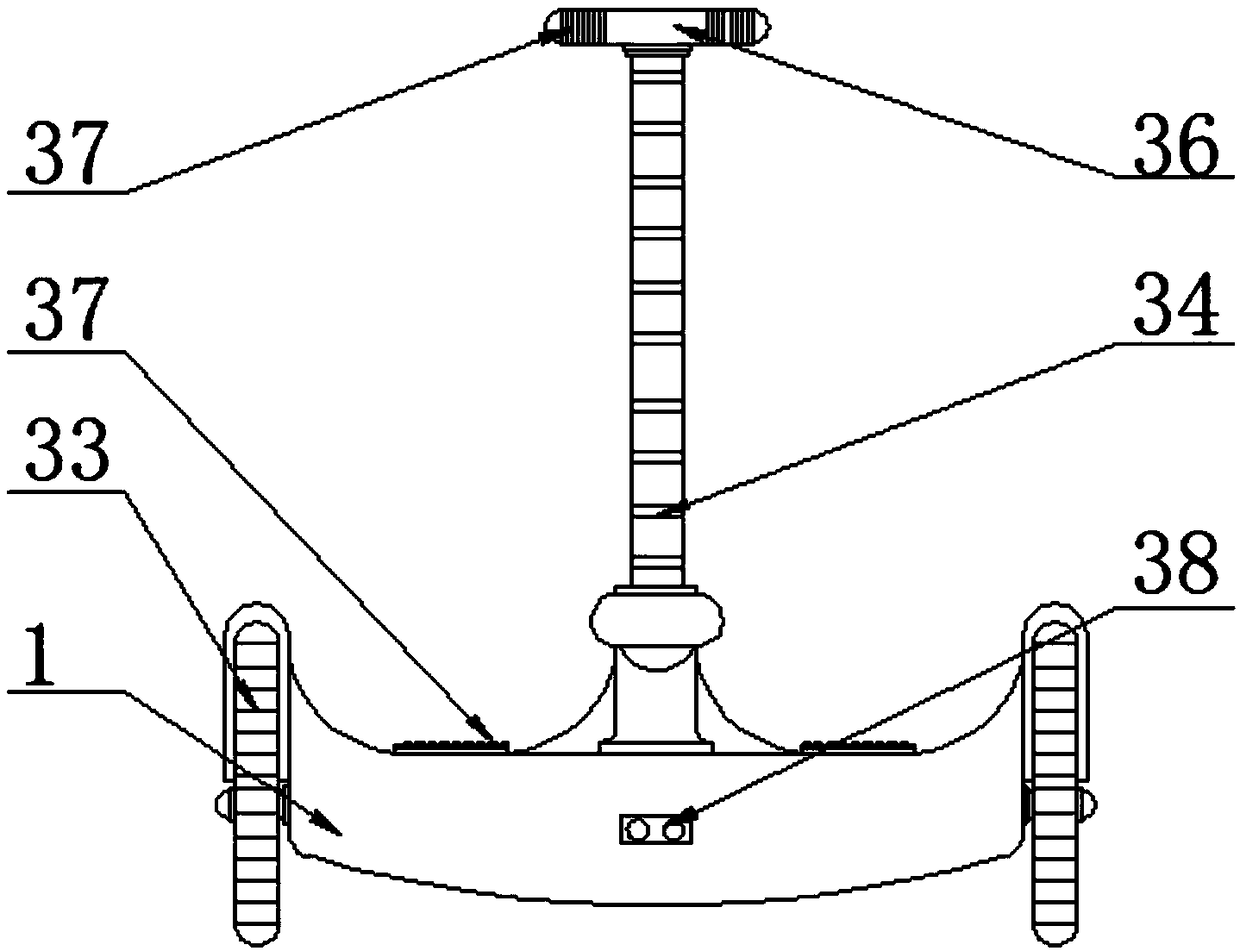

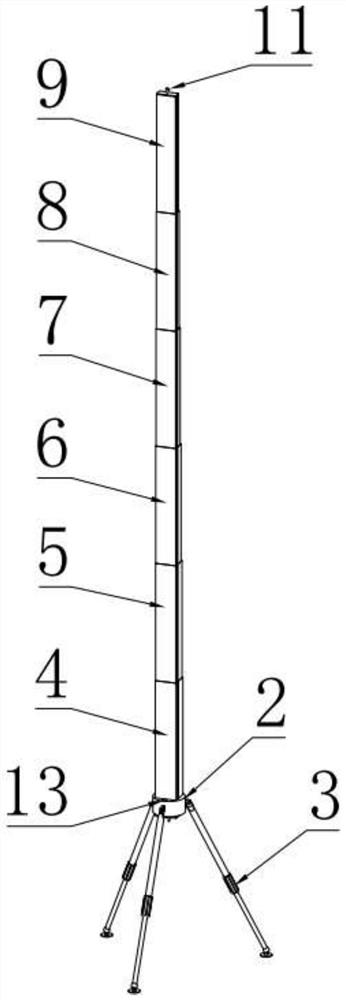

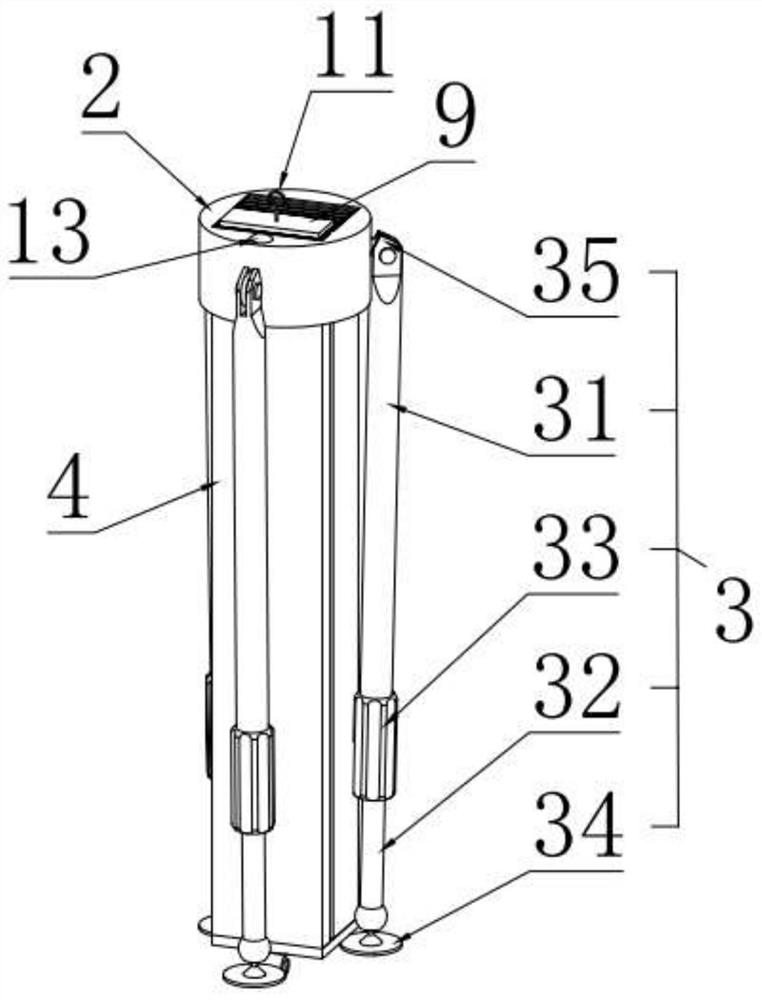

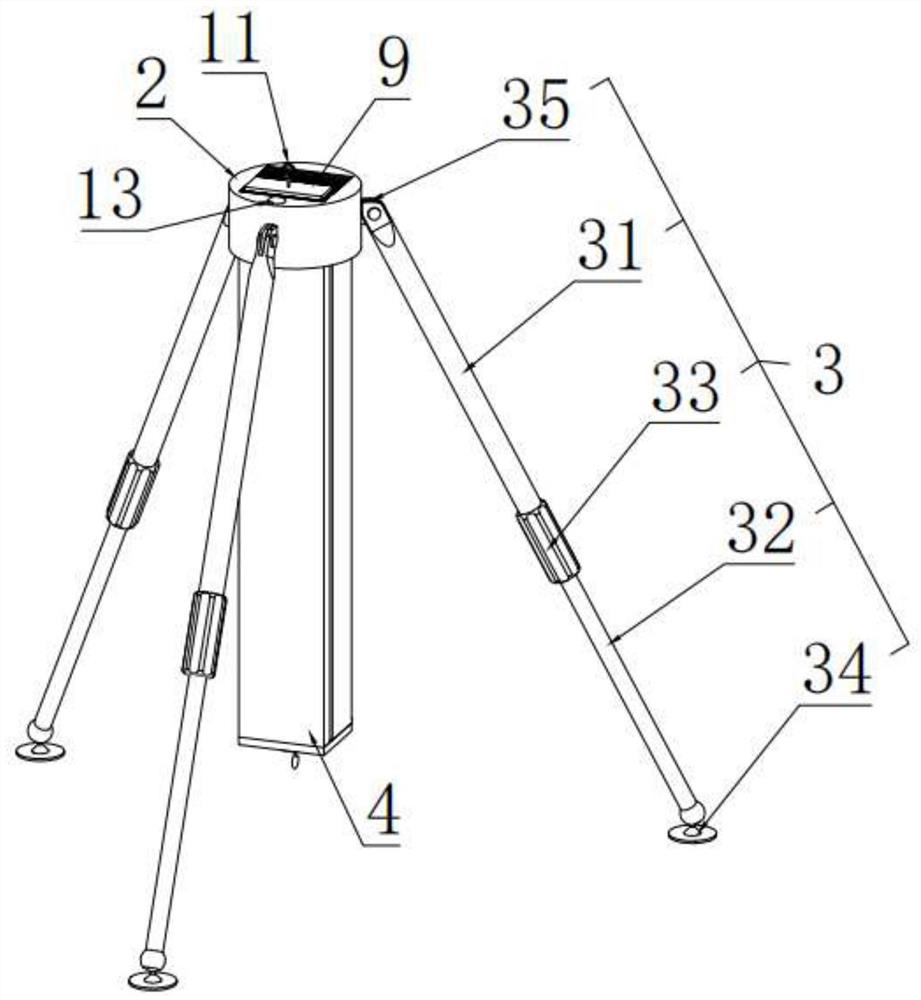

A Portable Tower Ruler for Large-Scale Topographic Surveying and Mapping

The invention discloses a portable tower ruler for large-scale topographic surveying and mapping, which comprises: a support plate; three support leg assemblies, which are respectively installed on the side walls of the contracted support plate along the circumferential direction through pin shafts; the first tower section, The second tower section is adapted to be inserted into the inner cavity of the first tower section; the third tower section is adapted to be inserted into the second tower section. The inner cavity of the tower section; the fourth tower section is adapted to be inserted into the inner cavity of the third tower section; the fifth tower section is adapted to be inserted into the inner cavity of the fourth tower section. The portable tower ruler for large-scale topographic surveying and mapping can realize the straightening of the tower ruler in any environment and landform, without the need for manual support, avoiding the fatigue of the operator caused by long-term support and walking, and ensuring the stability of the leveling ruler Stable and accurate measurement results, and can be stretched and contracted quickly, easy to operate, saving time and effort.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com