Connecting structure of fabricated square steel

A connection structure and prefabricated technology, applied in the direction of building structure and construction, can solve the problems of inconvenient operation, hidden dangers, light pollution and air pollution, and achieve the effect of reliable connection and improved installation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

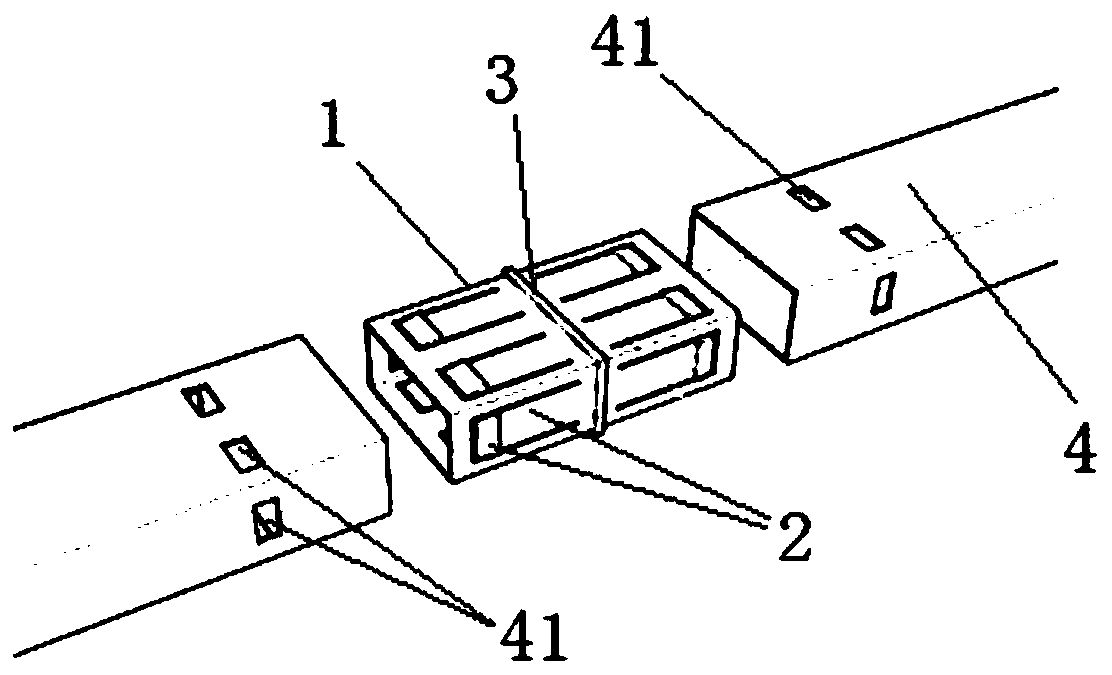

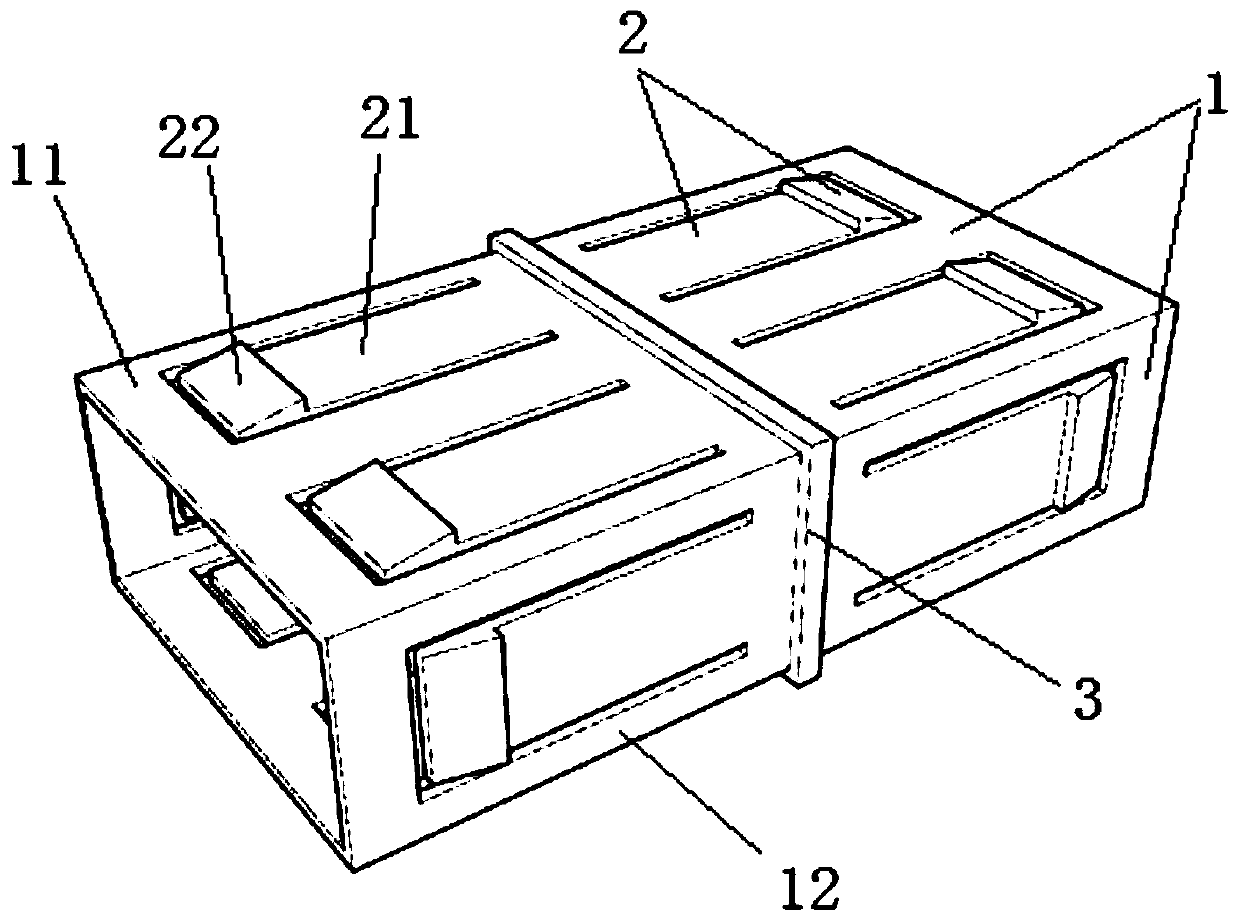

[0030] see Figure 1 to Figure 5 , the figure shows an assembled square steel connection structure provided by Embodiment 1 of the present invention, including: a connecting piece, which includes a connecting pipe 1, a connecting claw 2 and a limit bar 3, and the connecting claw 2 and a limit bar 3 are arranged on the outer wall of the connecting pipe 1; along the length direction, the limit strip 3 is located in the middle of the connecting pipe 1; Connecting claw 2; Square steel 4, its end is provided with connecting hole 41, and the position of connecting hole 41 is set correspondingly with the position of connecting claw 2; Phase card connection. Specifically, the connecting hole 41 is a square hole.

[0031] The connection structure of an assembled square steel provided in this embodiment mainly includes a square steel 4 and a connecting piece, the connecting piece includes a connecting pipe 1, a connecting claw 2 and a limit bar 3, and the square steel 4 is provided wi...

Embodiment 2

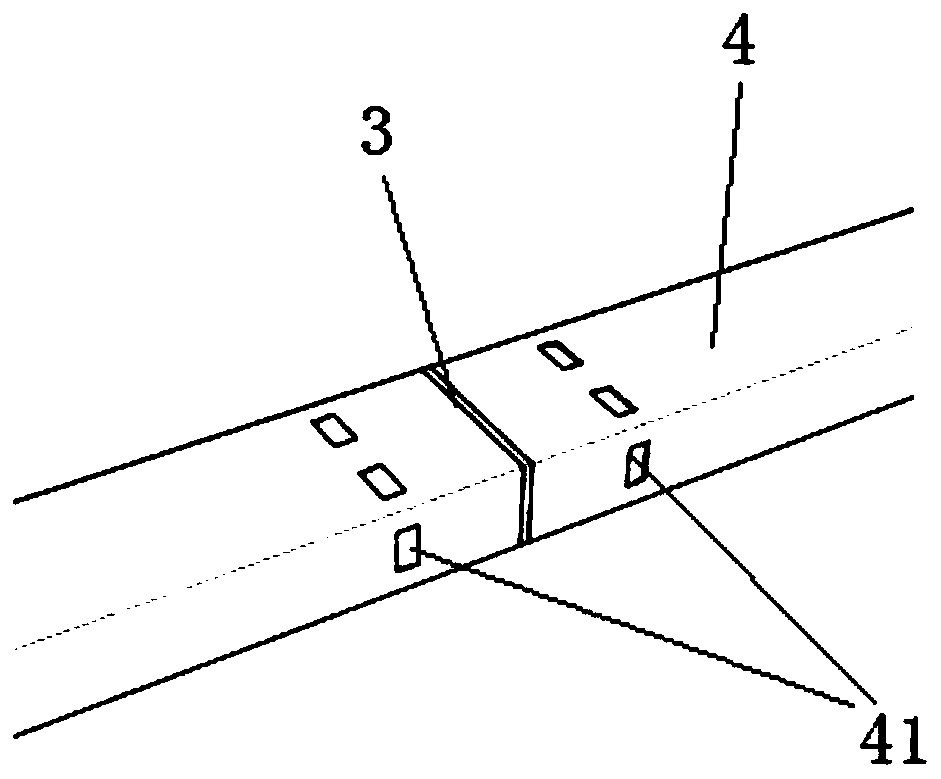

[0039] see Figure 3 to Figure 5 , the figure shows an assembled square steel connection structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: Limiting strips 3 is continuously arranged along the four sides of the connecting pipe 1; the height of the limit bar 3 is greater than the thickness of the pipe wall of the square steel 4. Through the arrangement of the above structure, it is possible to effectively prevent the square steel 4 from inserting the entire connecting piece, resulting in failure to connect.

Embodiment 3

[0041] see Figure 3 to Figure 5 , the figure shows an assembled square steel connection structure provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: connecting claw 2 It includes a connecting bar 21 protruding from the connecting pipe 1 and a connecting block 22 connected to the connecting bar 21. The connecting block 22 is located outside the connecting pipe 1; the side of the connecting block 22 is triangular, and the large end is located on the connecting pipe. 1 inside. Through the arrangement of the above structure, the connection strength between the connection claw 2 and the connection hole 41 can be improved, and the falling off phenomenon is not easy to occur.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com