Shoemaking production line with independent working tooling plate

A single work, tooling board technology, applied in the direction of shoe-making machinery, footwear, clothing, etc., can solve the problems of defective product line stop recycling, easy fatigue, high labor intensity of workers, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

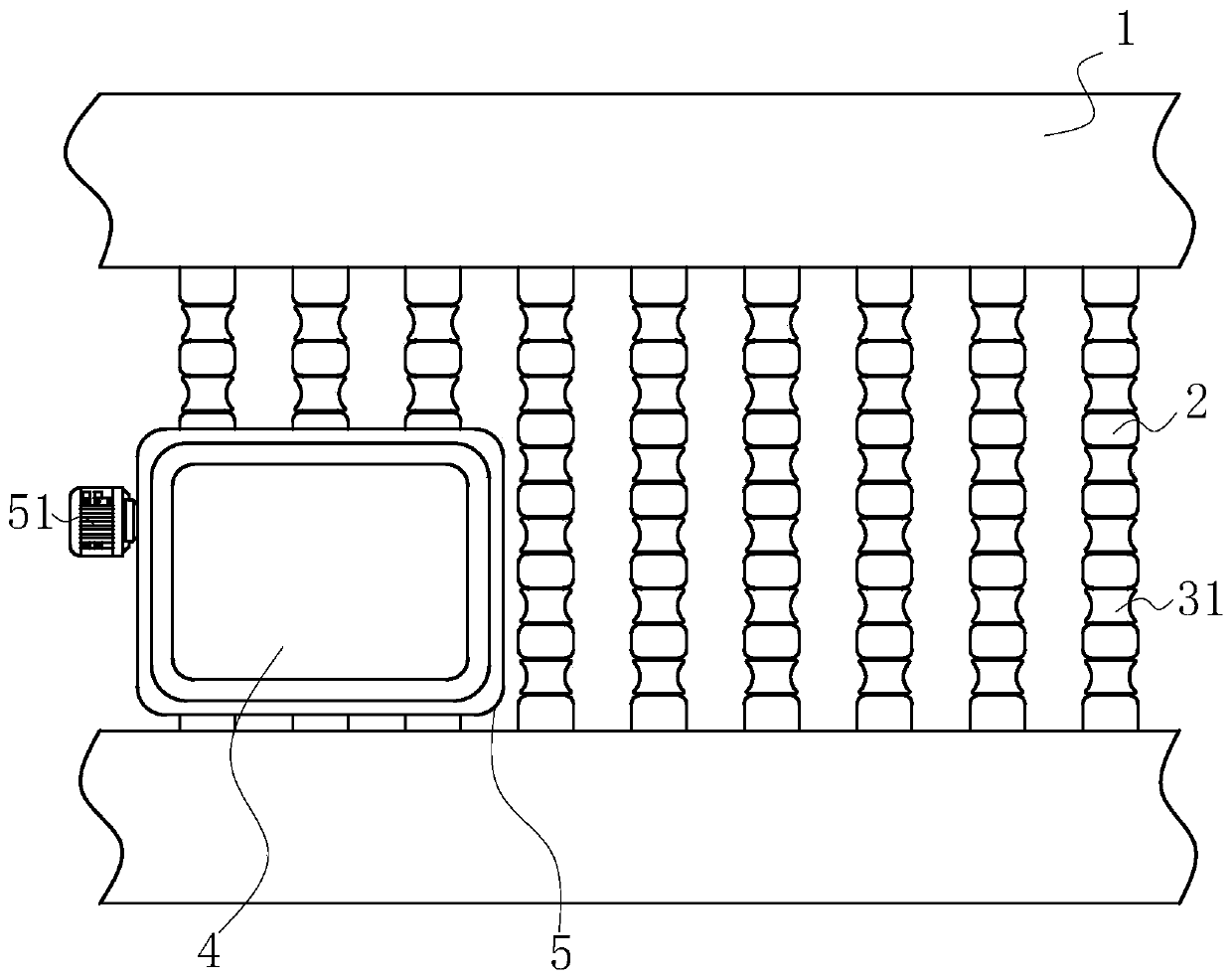

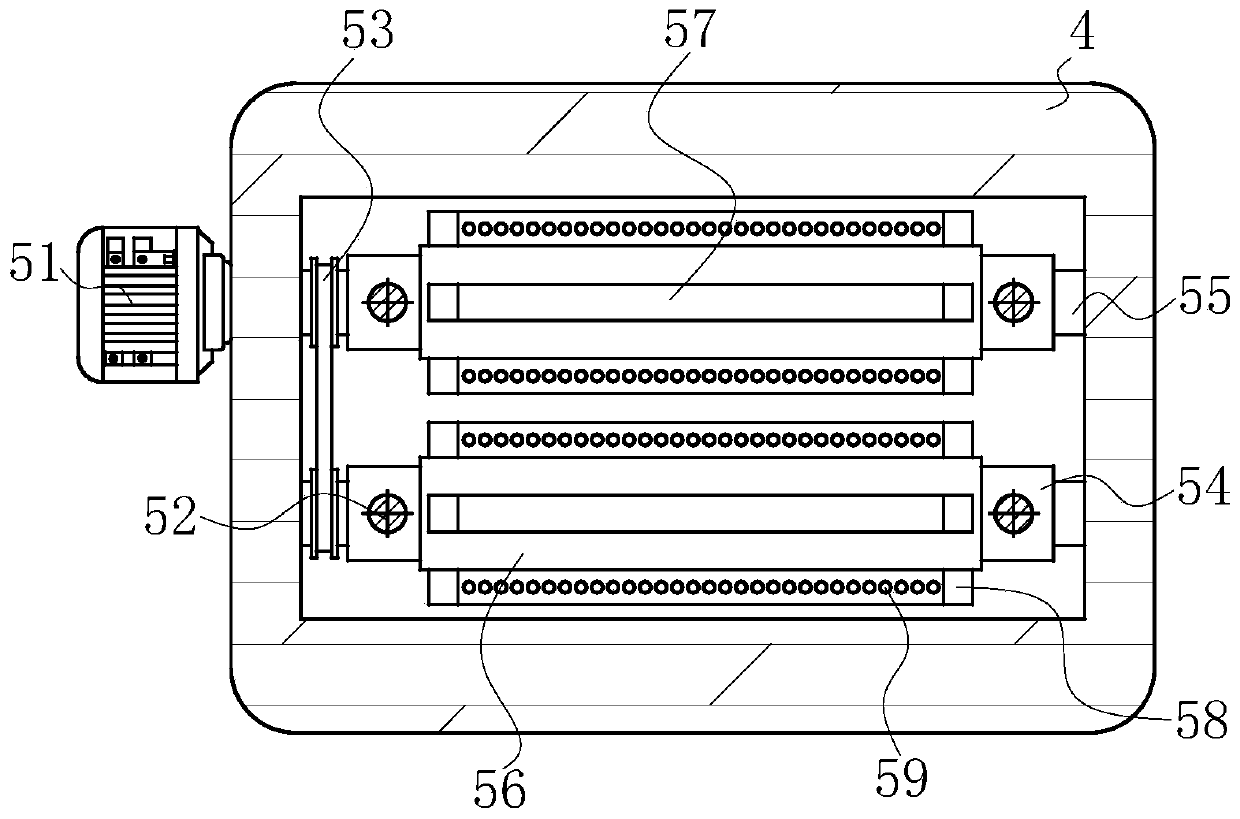

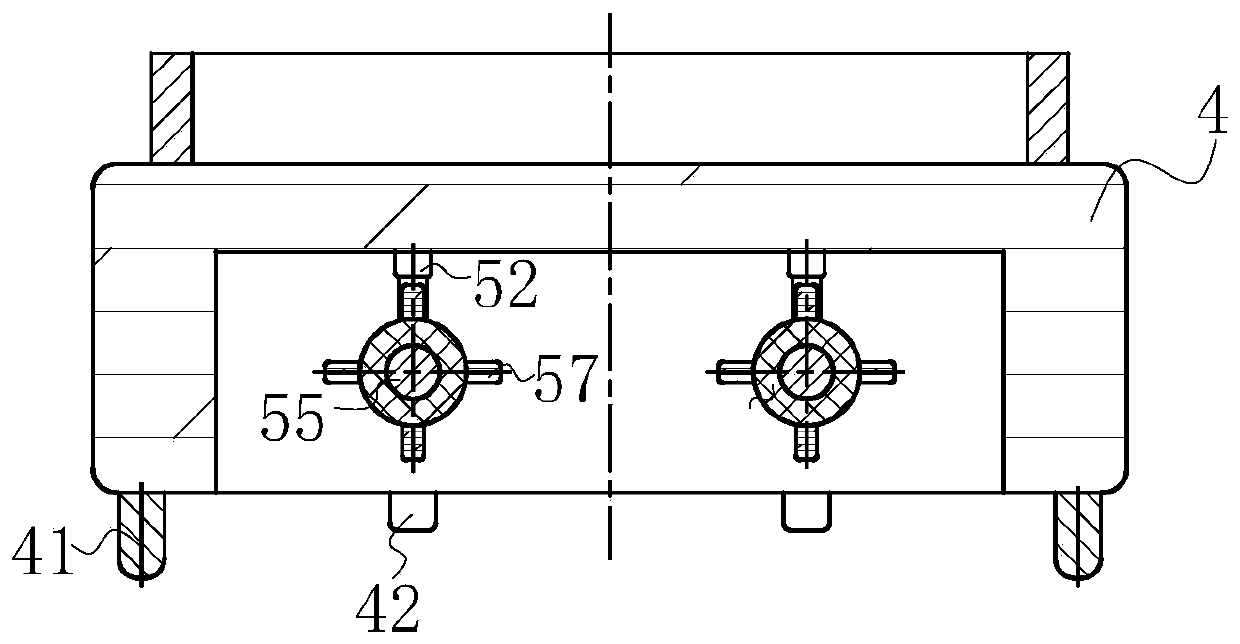

[0019] use Figure 1-Figure 4 A shoe-making assembly line with a single working tooling board according to an embodiment of the present invention will be described as follows.

[0020] Such as Figure 1-Figure 4As shown, a shoe-making assembly line with a tooling plate that works independently according to the present invention includes a rectangular plate 1, a transmission shaft 2, a mounting groove 3, a tooling plate 4 and a shifting mechanism 5; the rectangular plate 1 is parallel to There are two, the inner wall of the rectangular plate 1 is uniformly rotated and connected with the transmission shaft 2; the wall of the transmission shaft 2 is evenly provided with a mounting groove 3, and the top of the transmission shaft 2 is provided with a tooling plate 4; the installation groove 3 It is ring-shaped; the lower ends of the front and rear sides of the tooling plate 4 are fixedly equipped with a slide bar 41, and the inside of the tooling plate 4 is provided with a shift m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com