A kind of drying equipment for flame retardant materials of steel and wood fire doors

A technology for steel-wood fire doors and flame-retardant materials, which is applied in the field of drying equipment for fire-retardant materials for steel-wood fire doors. It can solve the problems of fire doors being damp, unable to remove water vapor, and poor processing effects, so as to prevent deformation and facilitate subsequent use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

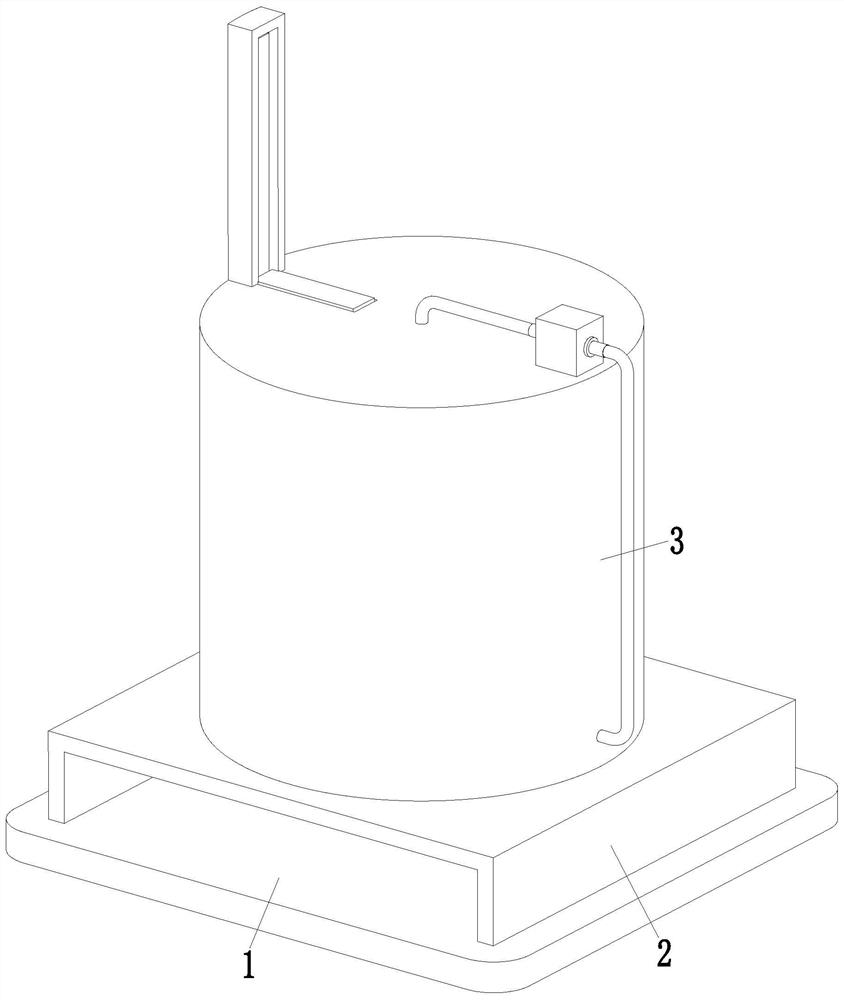

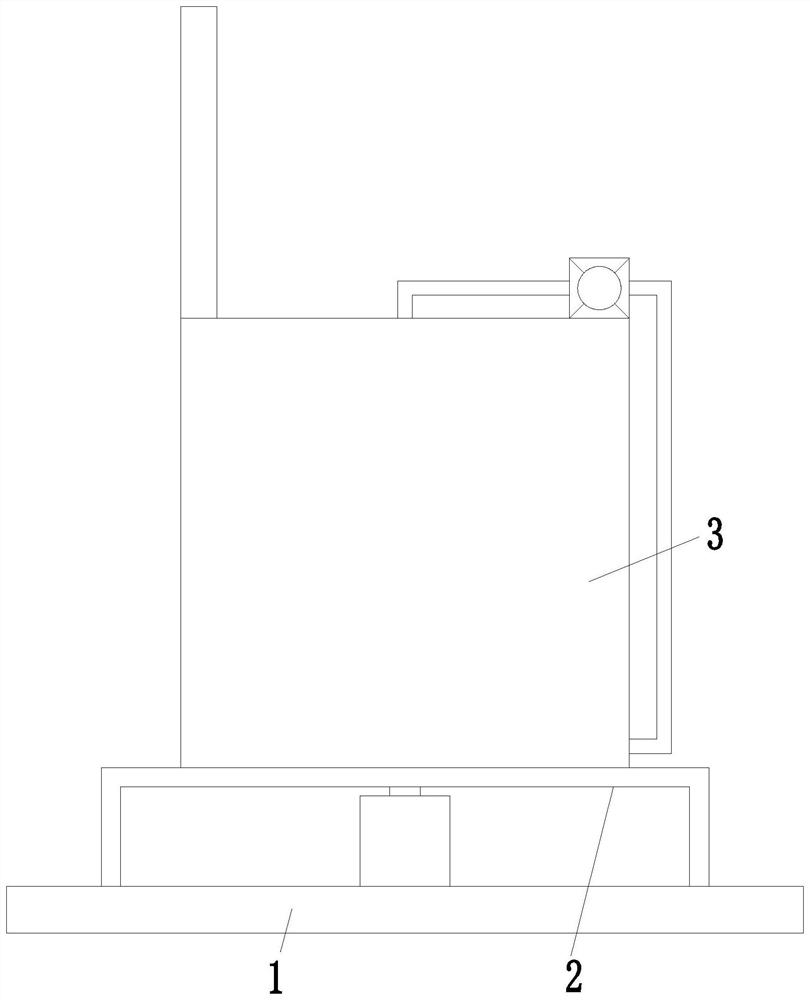

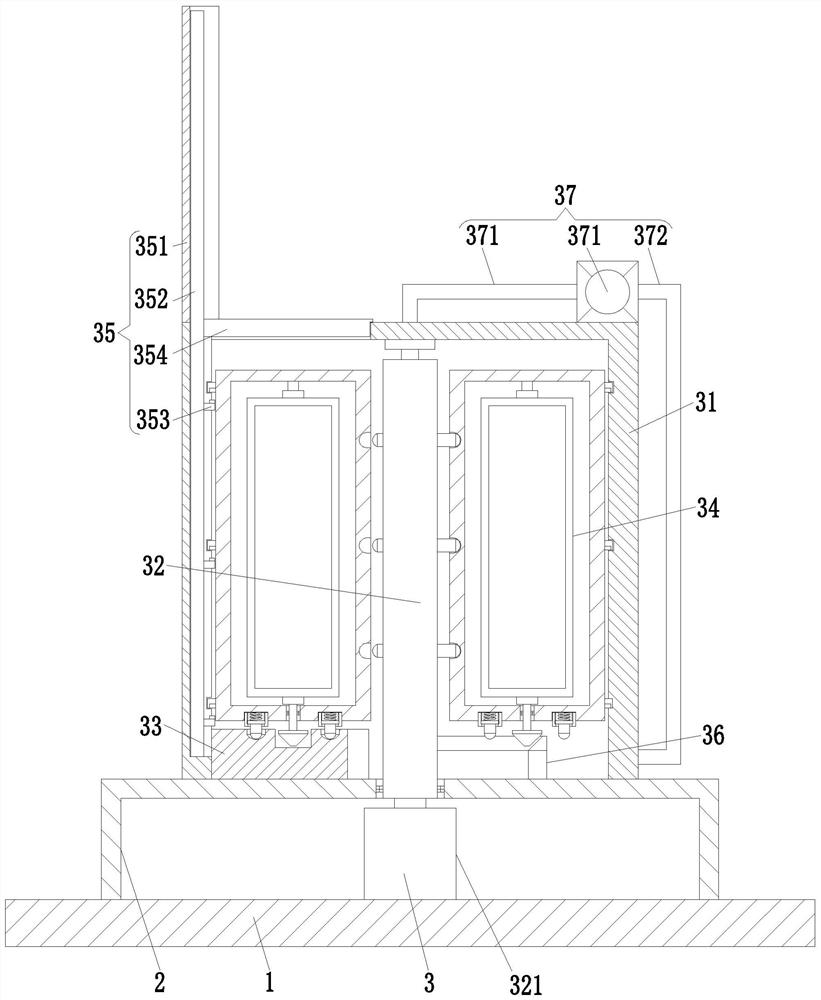

[0032] like Figure 1 to Figure 8 As shown in the figure, a fire-retardant material drying equipment for steel and wood fire doors includes a base frame 1, a support frame 2 and a drying assembly 3. The upper end of the base frame 1 is installed with a support frame 2, and the cross-section of the support frame 2 is U-shaped. Structure, a drying assembly 3 is installed in the middle of the upper end of the support frame 2 .

[0033] The drying assembly 3 includes a fixed cylinder 31, a rotating unit 32, a material storage rack 33, a drying rack 34, a lifting unit 35, an arc tooth plate 36 and a circulation unit 37. The fixed cylinder 31 is installed on the support frame. 2. In the middle of the upper end, the rotating unit 32 is installed in the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com