Preparation method of hydrophilic MOF (Metal Organic Framework) and application of prepared MOF as catalyst carrier

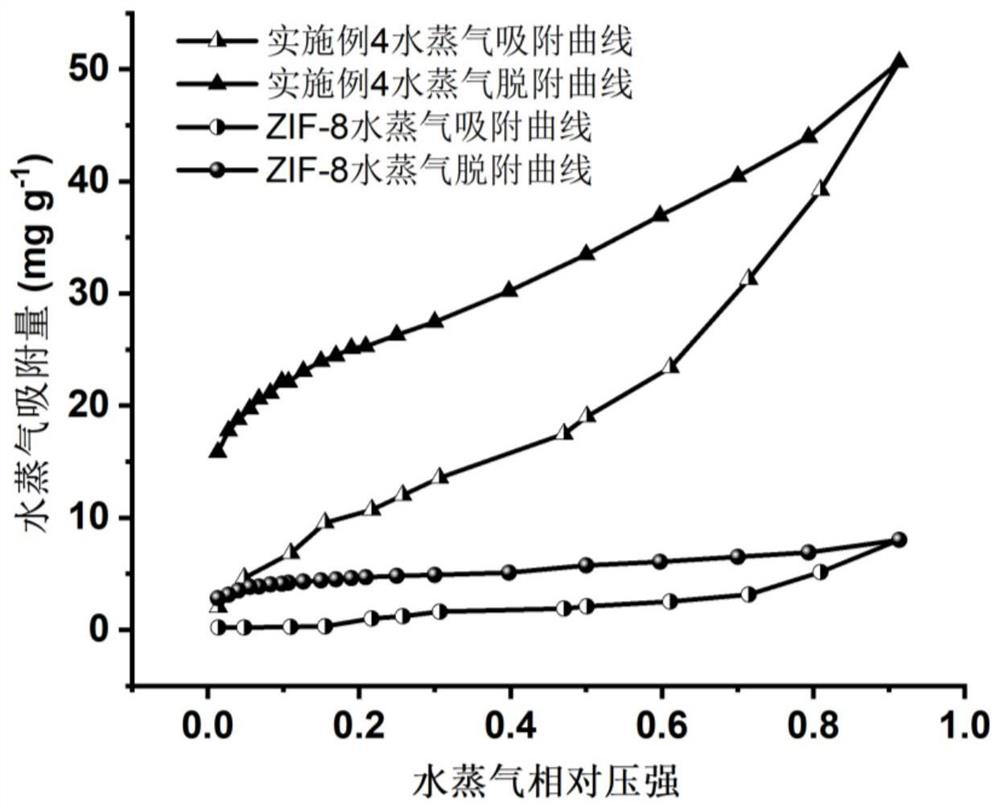

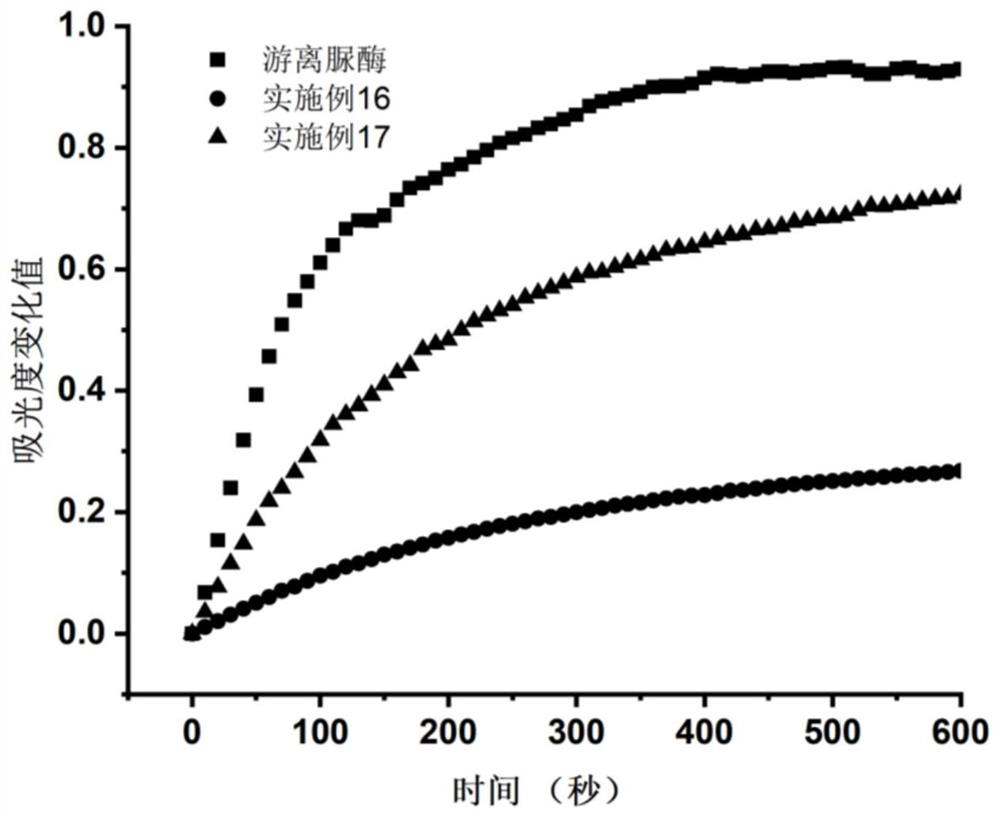

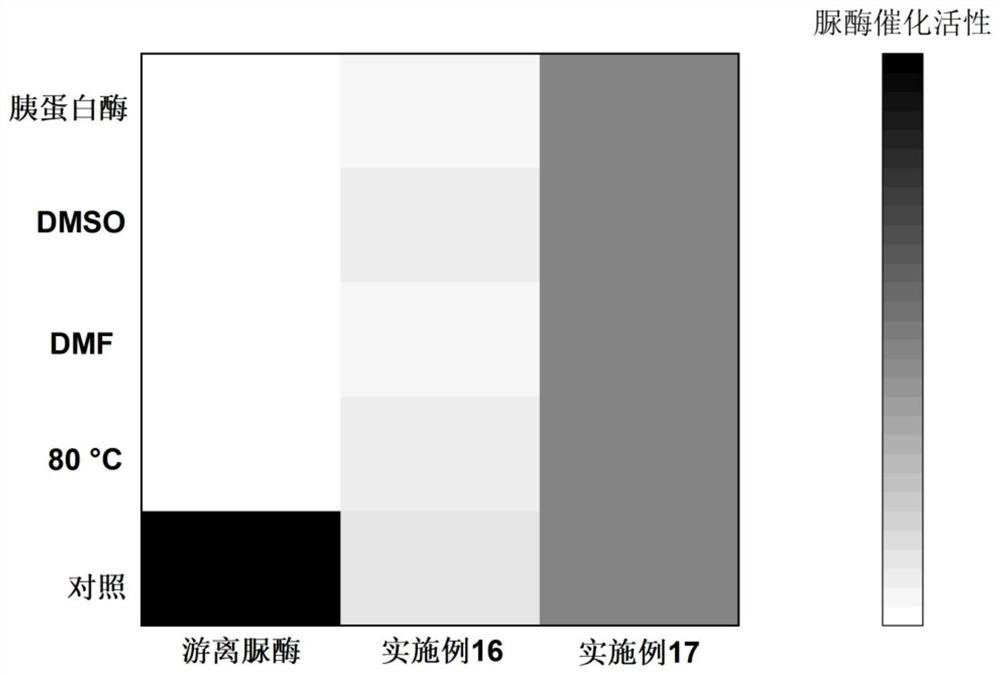

A hydrophilic, solvent-based technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc., can solve problems such as limited universality, cumbersome steps, and long time. , to achieve the effect of high-efficiency enzyme-catalyzed reaction, excellent hydrophilic performance and high structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Synthesis of ZIF-8 Modified by Sodium 12-Phosphotungstate (PW)

[0041] Solution A: 1.71g of zinc nitrate hexahydrate was dissolved in 45mL of methanol to prepare a solution.

[0042] Solution B: 3.6g of 2-methylimidazole was dissolved in 45mL of methanol to prepare a solution.

[0043] Solution C: 1 mg / mL PW aqueous solution.

[0044] Mix and stir 45mL of liquid A, 45mL of liquid B, and 6mL of liquid C for 5 minutes and let stand for at least 1 hour, then centrifuge to collect the product, wash with methanol and dry to obtain 12-sodium phosphotungstate (PW) modified ZIF-8 material , denoted as I-ZIF-PW-1, where the number 1 indicates that the concentration of the PW aqueous solution used is 1 mg / mL.

Embodiment 2

[0046] Except that C liquid is the PW aqueous solution of 2mg / mL, prepare the ZIF-8 material modified by 12-sodium phosphotungstate (PW) in the same manner as in Example 1, denoted as I-ZIF-PW-2, wherein The number 2 indicates that the concentration of the PW aqueous solution used is 2 mg / mL.

Embodiment 3

[0048] Except that C liquid is the PW aqueous solution of 3mg / mL, prepare the ZIF-8 material modified by 12-sodium phosphotungstate (PW) in the same manner as in Example 1, denoted as I-ZIF-PW-3, wherein The number 3 indicates that the concentration of the PW aqueous solution used is 3 mg / mL.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap