Wheel hub rapid paint spraying device for automobile beauty

A technology for car beauty and wheels, which is applied in the direction of spraying devices, spray booths, and devices for coating liquid on the surface, etc. It can solve problems such as time-consuming and energy-consuming, uneven spraying, etc., to reduce waiting time, avoid spraying, The effect of preventing offset position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

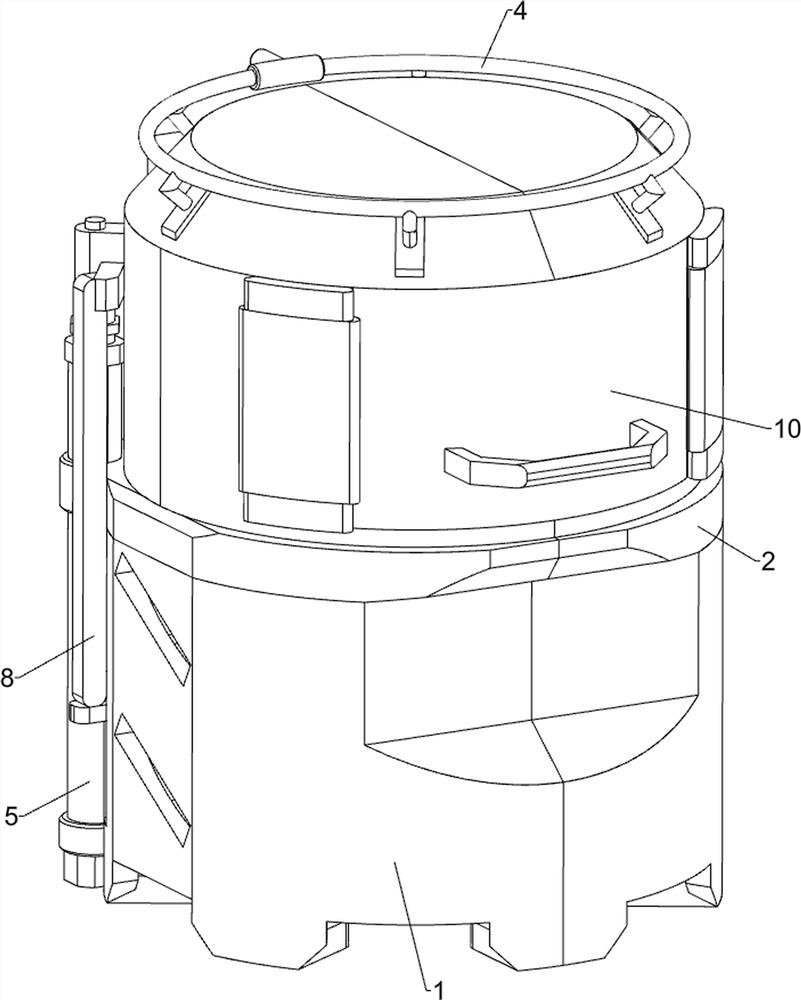

[0075] A kind of fast painting device for wheel hub for car beauty, such as Figure 1-Figure 7 As shown, it includes a bracket 1, a placement table 2, a painting assembly 3, a material guide tube 4, a lifting mechanism 5 and a rotating mechanism 6. The top of the bracket 1 is provided with a placement platform 2, and the rear side of the bracket 1 is provided with a lifting mechanism 5. The lifting mechanism A plurality of paint spraying assemblies 3 are evenly spaced on the top 5, a material guide pipe 4 is provided between the outsides of the paint spraying assemblies 3, and a rotating mechanism 6 is provided on the inside of the bracket 1.

[0076] The elevating mechanism 5 includes a first support block 50, a cylinder 51, an arc baffle plate 52, a second support block 53 and an air duct 54, and the left and right sides of the lower rear side of the support 1 are symmetrically provided with the first support block 50, and the first support block 50 Cylinders 51 are arranged...

Embodiment 2

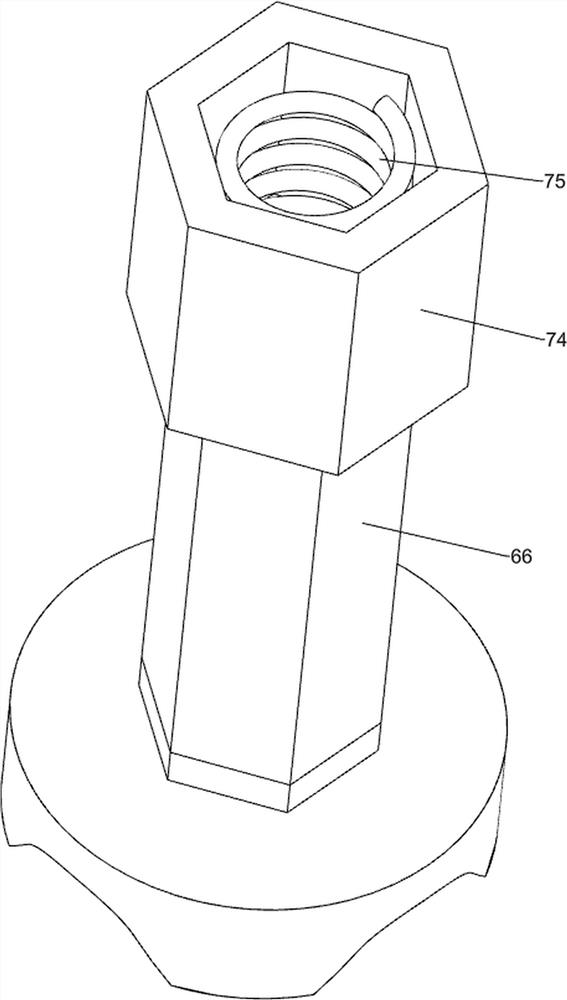

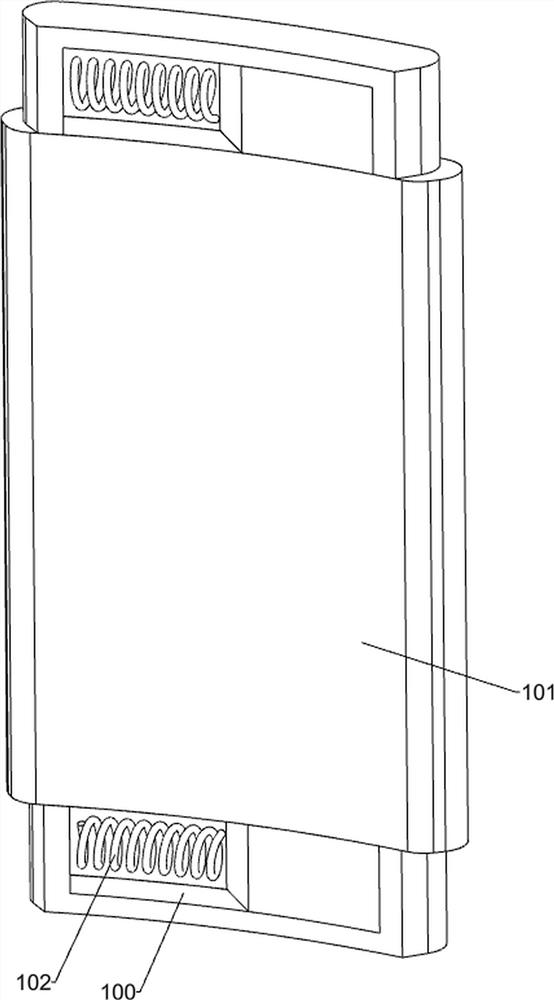

[0080] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 and Figure 15 As shown, a clamping assembly 7 is also included, and the clamping assembly 7 includes a limit rod 70, a second guide rod 71, a wedge block 72, a second spring 73, a guide sleeve 74 and a third spring 75, and the upper part of the outer side of the sliding shaft 66 Three spacer rods 70 are arranged at intervals, and three groups of second guide rods 71 are arranged at intervals on the lower side of the positioning plate 67 inner wall, and the number of each group is 2, and wedge-shaped blocks 72 are slidingly arranged between the inner sides of each group of second guide rods 71 . A second spring 73 is wound around the second guide rod 71, and the two ends of the second spring 73 are respectively connected with the wedge-shaped block 72 and the positioning plate 67. A guide sleeve 74 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com