Precise stamping forming equipment for arc-shaped bottom cover of boiler

A technology of precision stamping and forming equipment, applied in the direction of pushing out equipment, metal processing equipment, feeding devices, etc., can solve the problems of low precision and complicated operation, and achieve the effect of easy collection and processing, and convenient follow-up operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

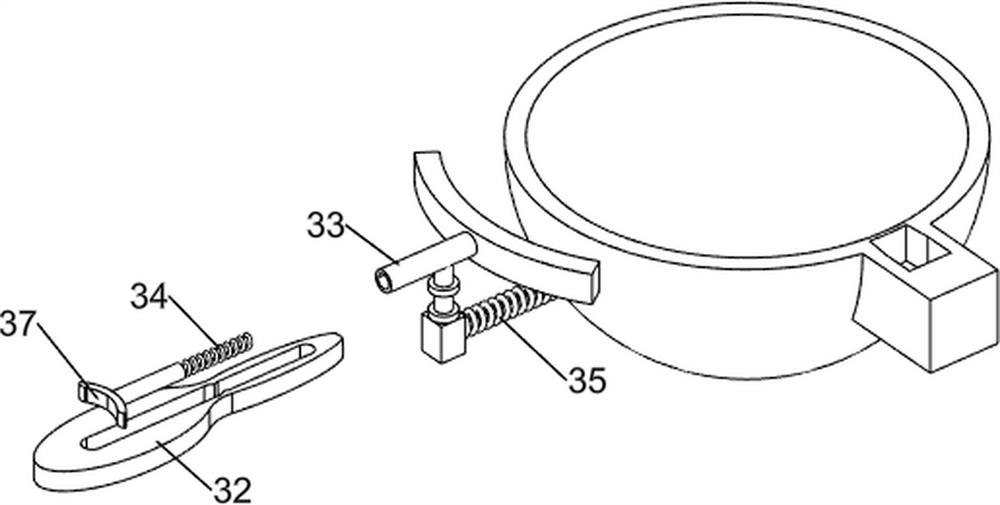

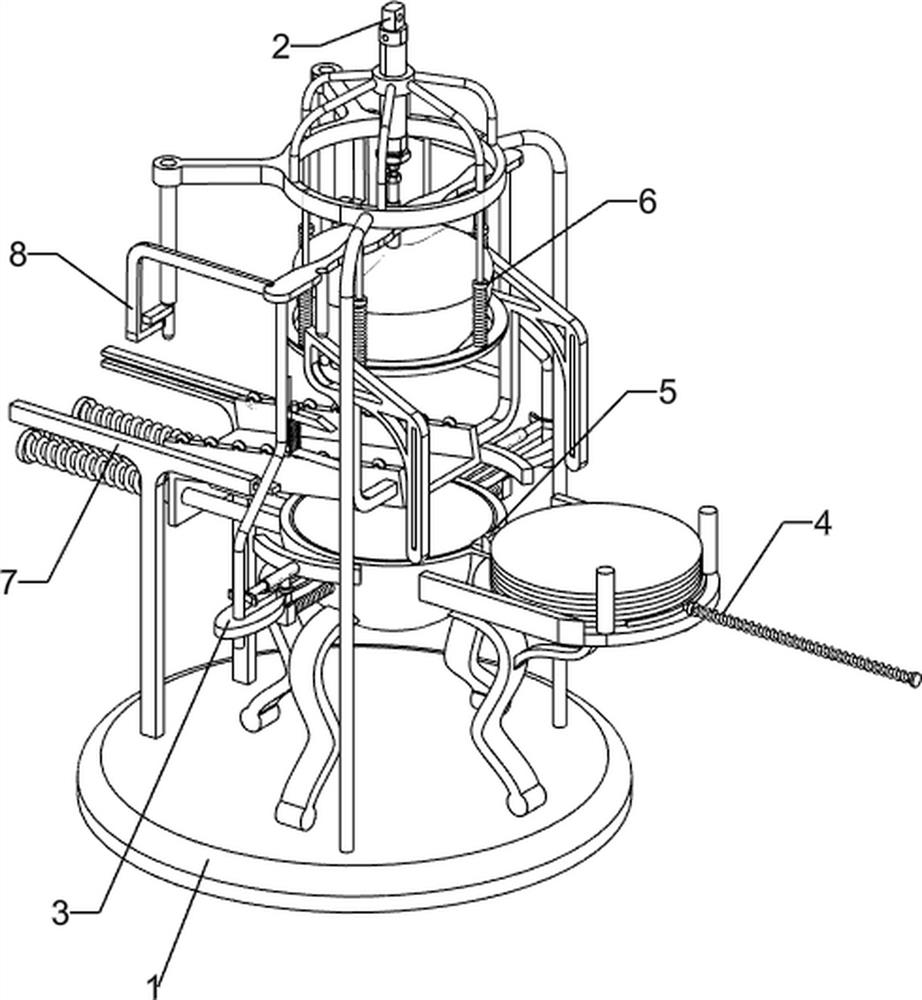

[0068] A precision stamping and forming equipment for a boiler arc bottom cover, such as figure 1 As shown, it includes a base 1 , a punching mechanism 2 and a fastening mechanism 3 , the punching mechanism 2 is connected to the upper side of the base 1 , and a plurality of fastening mechanisms 3 are connected to the upper side of the base 1 .

[0069]When the equipment needs to be practical, the user can place the raw material plate on the fastening mechanism 3, start the punching mechanism 2, and the telescopic rod of the punching mechanism 2 is extended, so that the punching mechanism 2 moves downward to achieve the For the purpose of punching the plate, the punching mechanism 2 moves downward to drive the fastening mechanism 3 to move downward. When the fastening mechanism 3 is in contact with each other, the fastening mechanism 3 is pushed to slide inward. At this time, the fastening mechanism 3 is compressed. Clamp the raw material plate to achieve the purpose of clampin...

Embodiment 2

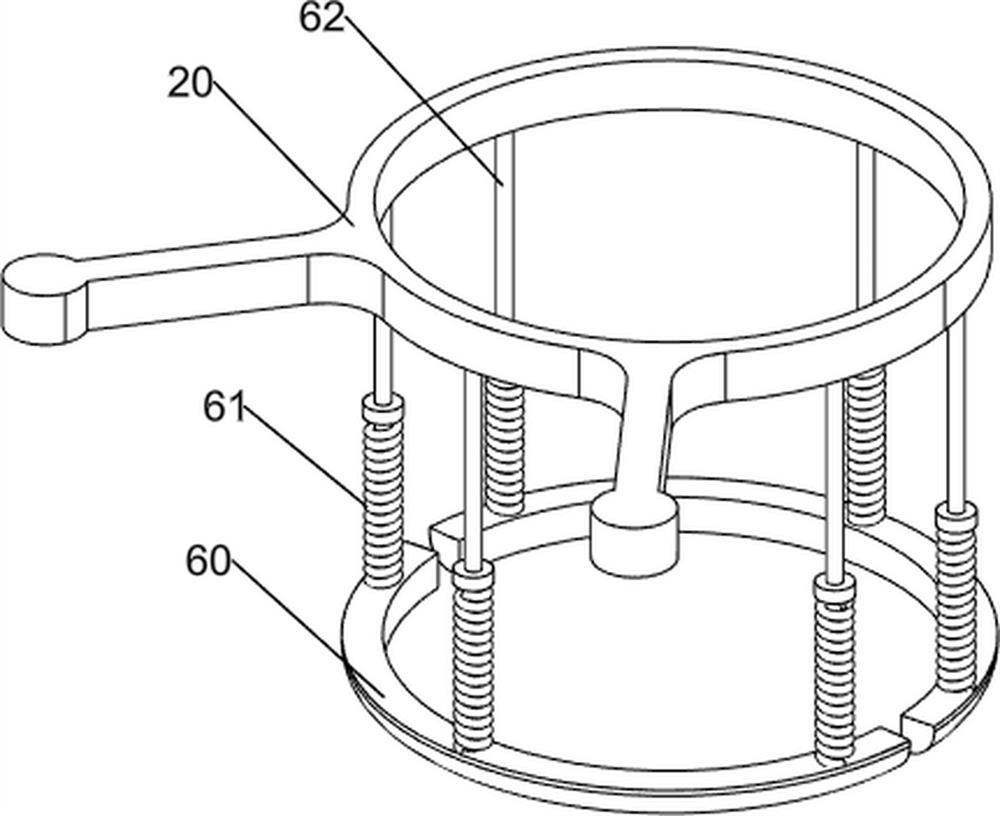

[0071] On the basis of Example 1, such as figure 2 As shown, the punching mechanism 2 includes a second support frame 20, a cylinder 21 and a gravity block 22, the upper side of the base 1 is connected with the second support frame 20, the inner side of the second support frame 20 is connected with a cylinder 21, and the cylinder 21 passes through the first Two support frames 20, a gravity block 22 is connected on the expansion rod of the cylinder 21, and a pressure bar 23 is connected on the gravity block 22.

[0072] When the device needs to be practical, the user can place the raw material plate on the fastening mechanism 3, start the cylinder 21, the stretch rod of the cylinder 21 drives the gravity block 22 to move downward, and the gravity block 22 moves downward to drive the pressure rod 23 Moving down to achieve the purpose of stamping the raw material plate, the downward movement of the pressure rod 23 drives the fastening mechanism 3 to move downward, and the follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com