Telescopic jig for eliminating tolerance of shipment material belt

A jig and material belt technology, applied in metal processing and other directions, can solve the problems of increasing product man-hours, occupying die-cutting machines and workers, etc., to achieve the effect of increasing production capacity, reducing die-cutting processes, and eliminating tolerances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

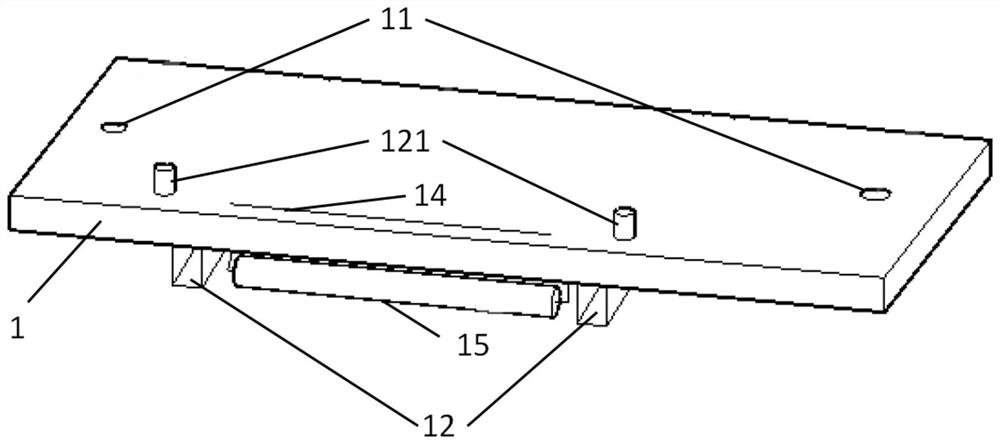

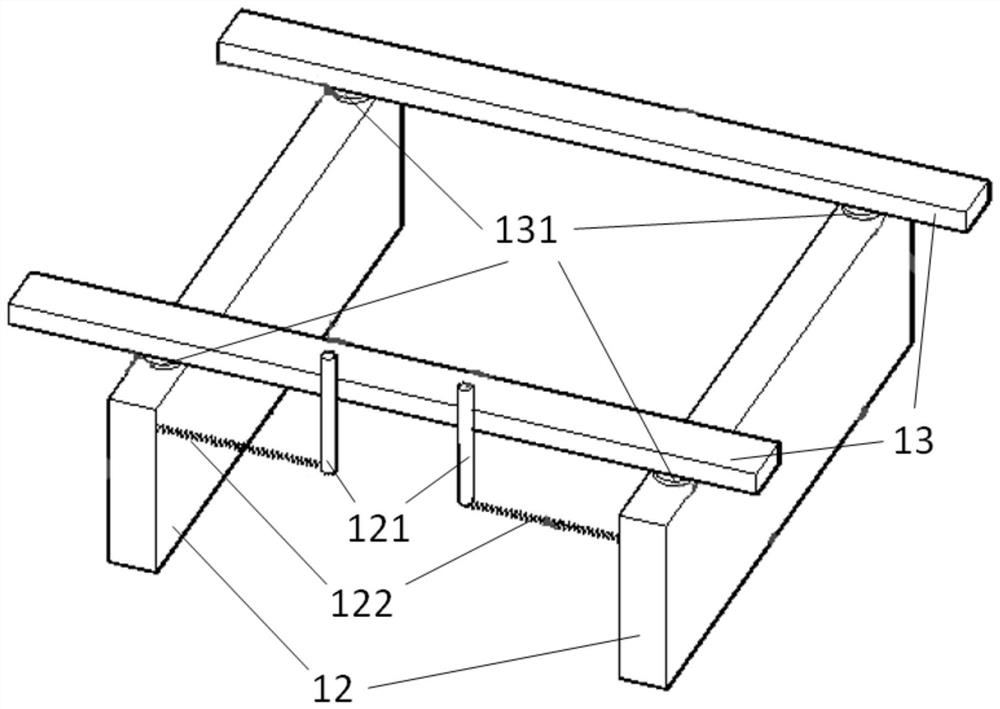

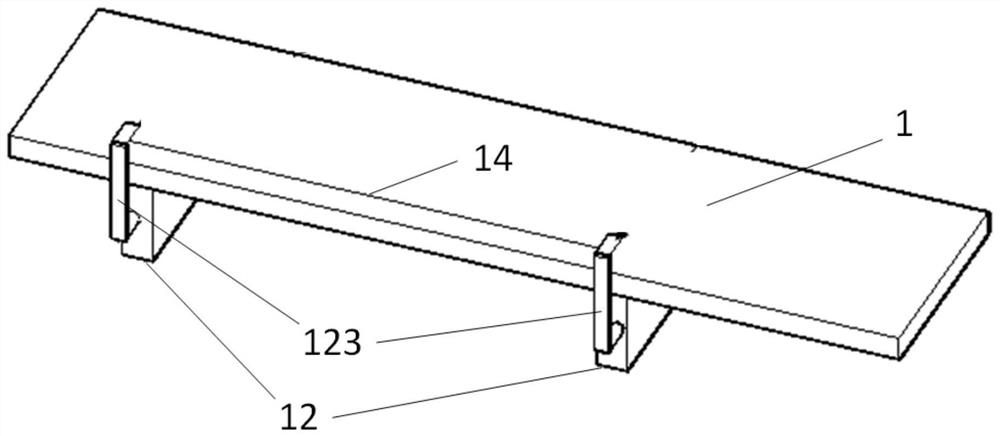

[0031] A retractable jig that eliminates the tolerance of the shipping material, the jig includes a jig upper plate 1 and a jig lower plate 2, the jig upper plate 1 is provided with blades 12 with adjustable spacing, such as figure 1 , the blade 12 is slidably connected with the jig upper plate 1, and the jig lower plate 2 includes intermediate grooves 22 with adjustable spacing. When in use, the jig upper plate 1 and the jig lower plate 2 are matched and connected, including The semi-finished die-cut part of the material belt is located between the upper plate 1 of the jig and the lower plate 2 of the jig. Adjust the width of the blades in the blade group 12 according to the final demand, and cut the die-cut semi-finished product into the desired width. The same level, played a role in eliminating the tolerance. A sleeve hole 11 is also provided on the jig upper plate 1 , and a positioning pin 21 matching the sleeve hole 11 is also provided on the jig lower board 2 . A nut ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com