Drying treatment device for display screen rubber frame injection molding

The technology of drying treatment and drying device is applied in the field of drying treatment device for plastic frame injection molding of display screen, which can solve the problems of decomposition, silver ribbon-like flaws on product surface, material deterioration and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

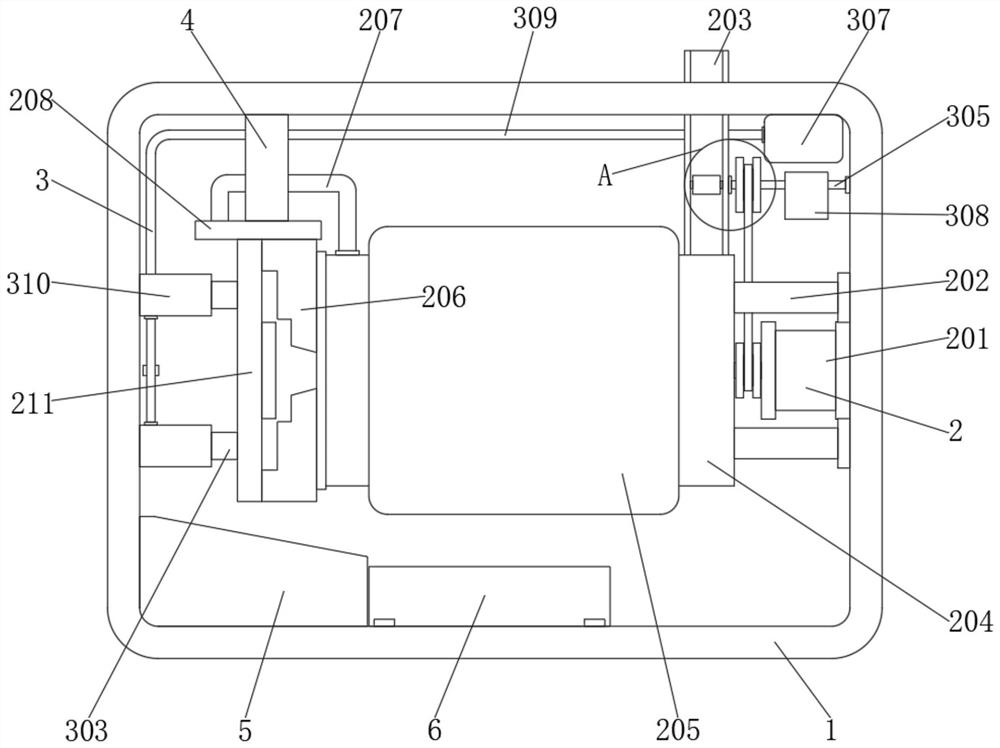

[0028] Example 1, such as Figure 1-6 As shown, the present invention provides a drying treatment device for plastic frame injection molding of a display screen, comprising an outer frame 1, a drying device 2 is arranged inside the outer frame 1 near the right side, and an auxiliary mechanism is arranged inside the outer frame 1 near the left side 3.

[0029] Let's talk about the specific settings and functions of the drying device 2 and the auxiliary mechanism 3 below.

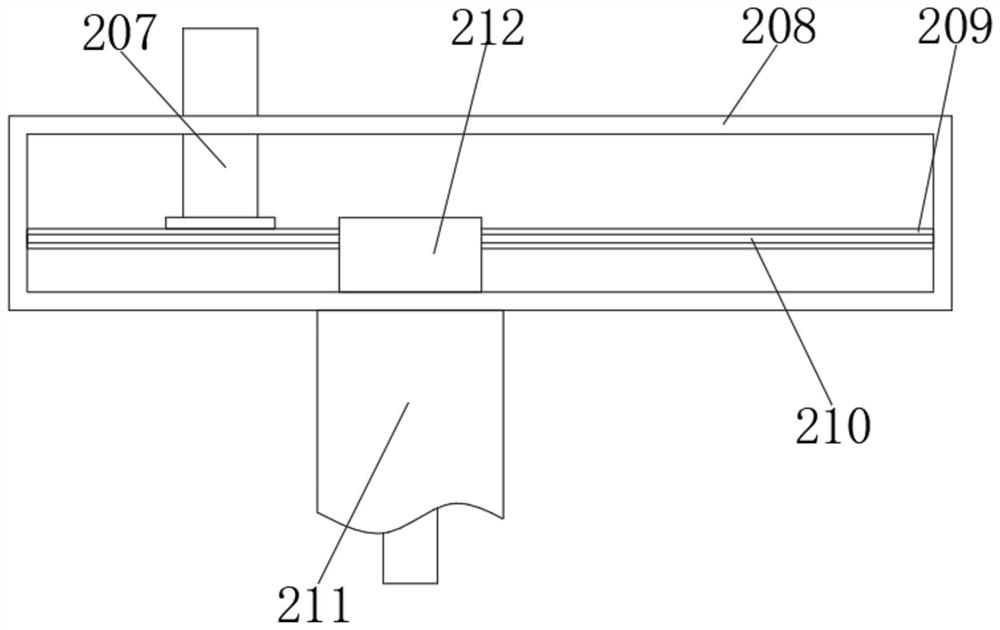

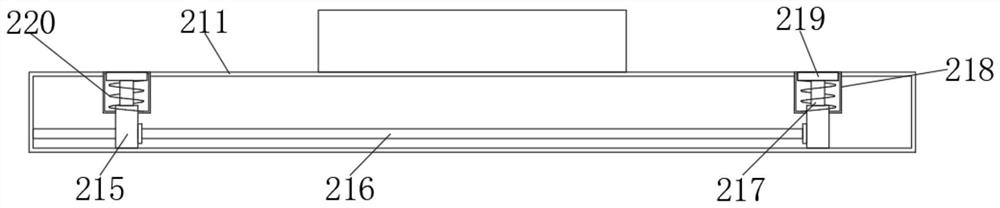

[0030] Such as Figure 1-6As shown, the drying device 2 includes a motor 201, the output end of the motor 201 is fixedly equipped with a feeding screw blade 221, and the end of the feeding screw blade 221 near the left side is fixedly installed with an inner box body 204, and the outer surface of the inner box body 204 is fixed. A heating device 205 is installed, a base 206 is fixedly installed on the left side of the inner box body 204, a first pipeline 207 is fixedly installed on the top of the inner box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com