Middle and rear floor framework

A rear floor and floor technology, which is applied in the field of vehicles, can solve the problems of low overlap between the beam and the threshold, difficult to achieve the collision star, and the beam cannot be used universally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

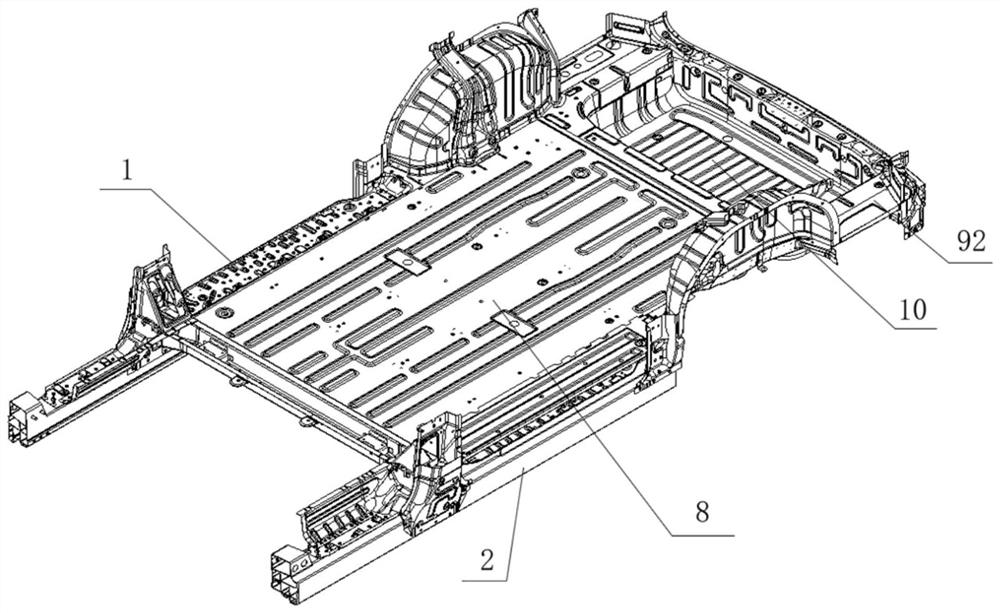

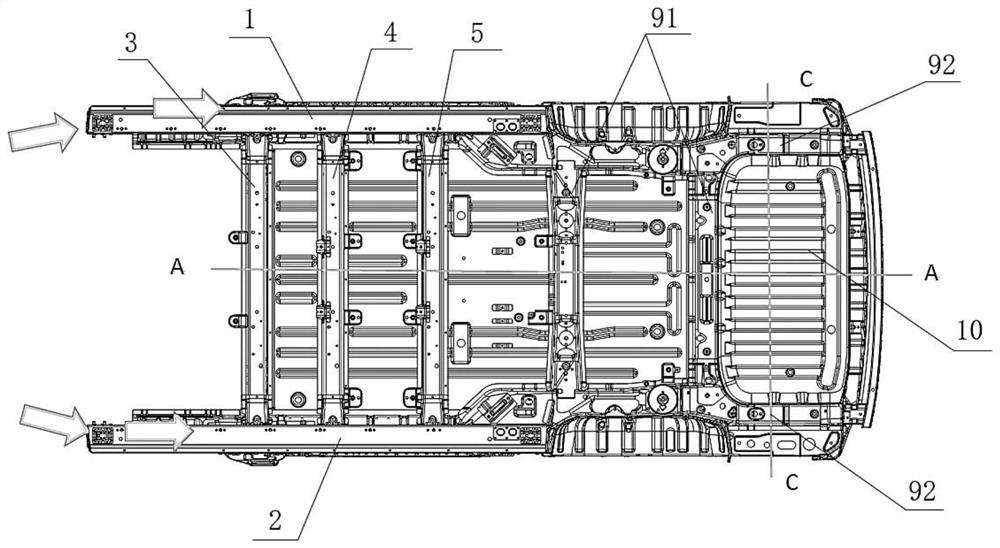

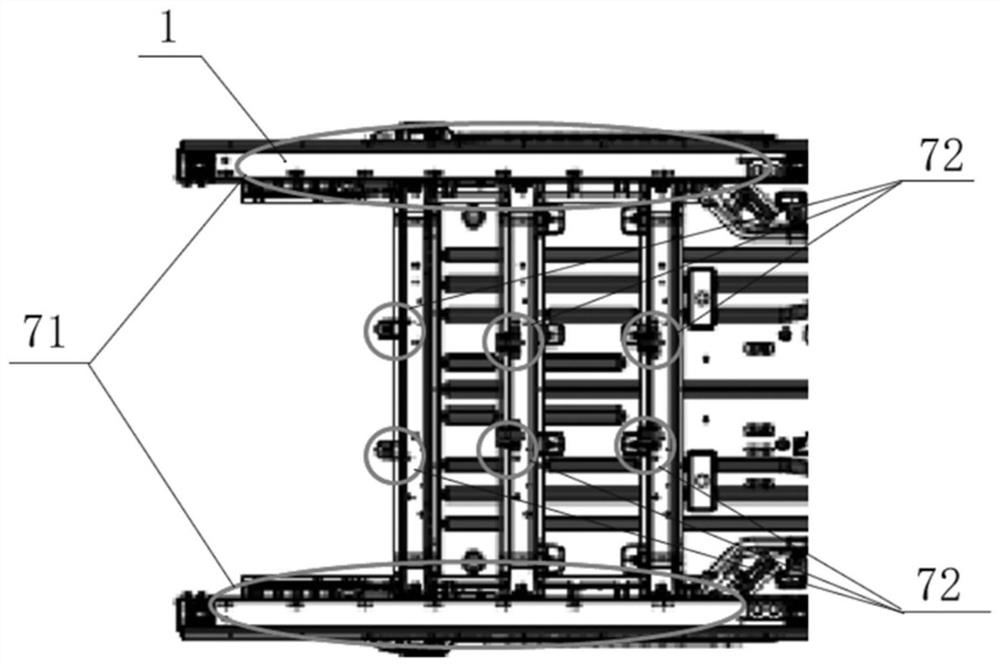

[0044] Such as figure 1 As shown, this embodiment provides a middle and rear floor structure, including a flat floor 8, a rear floor 9, a seat well 10, a middle floor frame structure and a battery pack 7, and the middle floor frame structure includes a beam assembly and a longitudinal beam assembly , the battery pack 7 is installed below the beam assembly, the flat floor 8 is installed above the beam assembly, the flat floor 8, the rear floor 9 and the seat pit 10 are connected in sequence, the beam assembly, the battery pack 7, the flat floor 8, and the rear floor 9 and the seat well 10 are supported by the stringer assembly.

[0045] The flat floor 8 is used for installing the second row of seats and the third row of seats, and the seat well 10 is used for installing the fourth row of seats.

[0046] Preferably, a seat long slide rail is laid on the upper surface of the flat floor 8 . Laying long seat slide rails can realize the common rail linkage of the second row and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com