Heating system with photoelectric heat source

A heating and photoelectric technology, applied in solar heating systems, energy industries, heating devices, etc., can solve the problems of low energy utilization, low thermal efficiency, hidden dangers of electric leakage, etc., and achieve the effect of saving building installation costs and a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

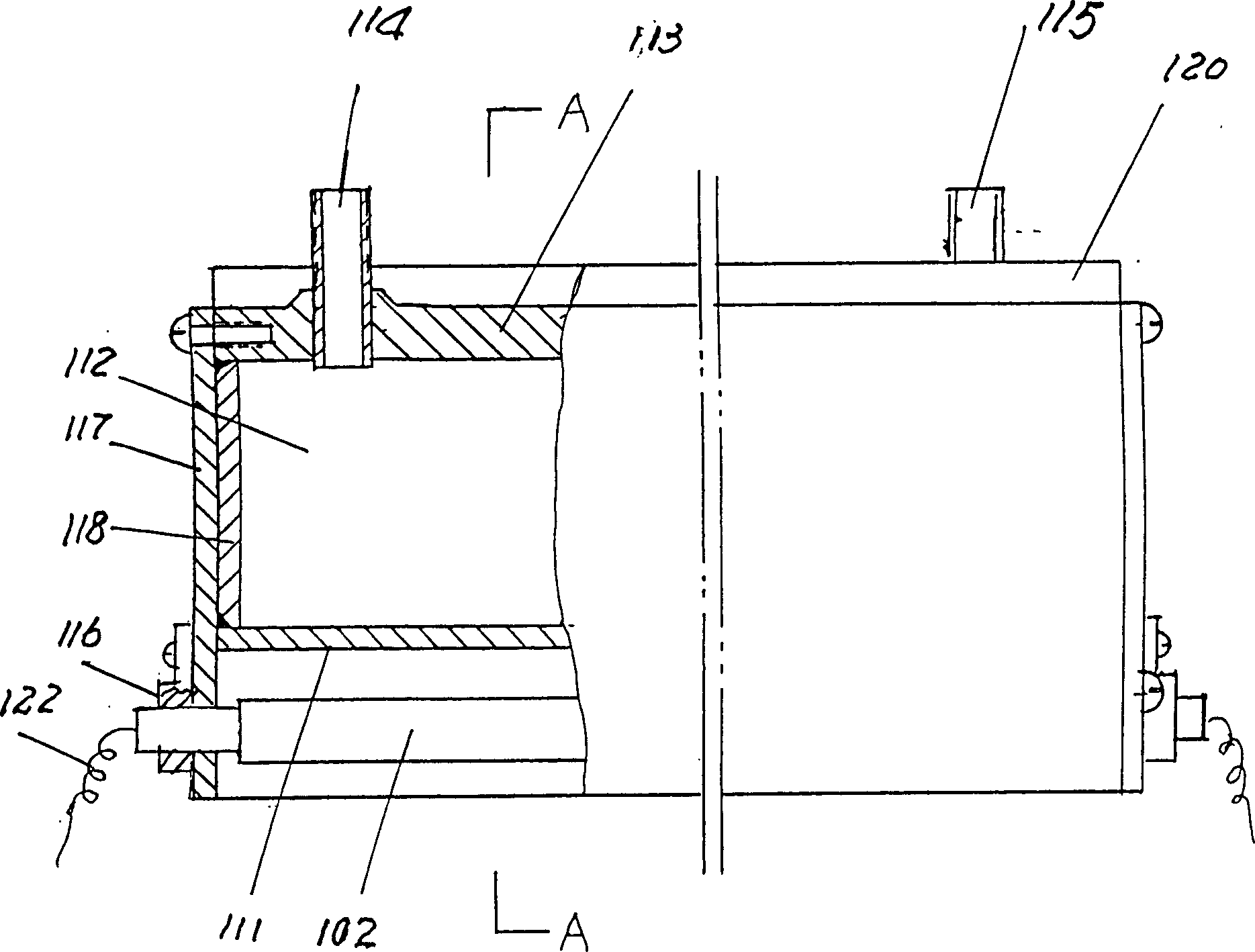

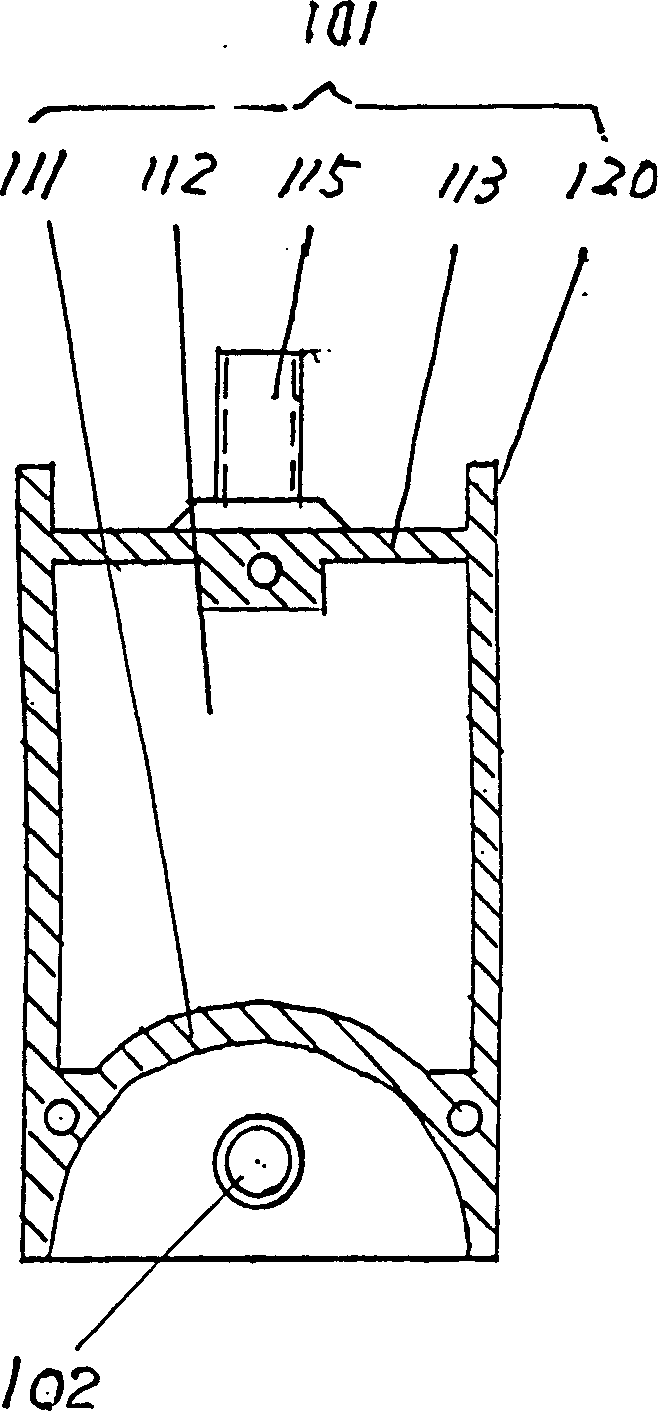

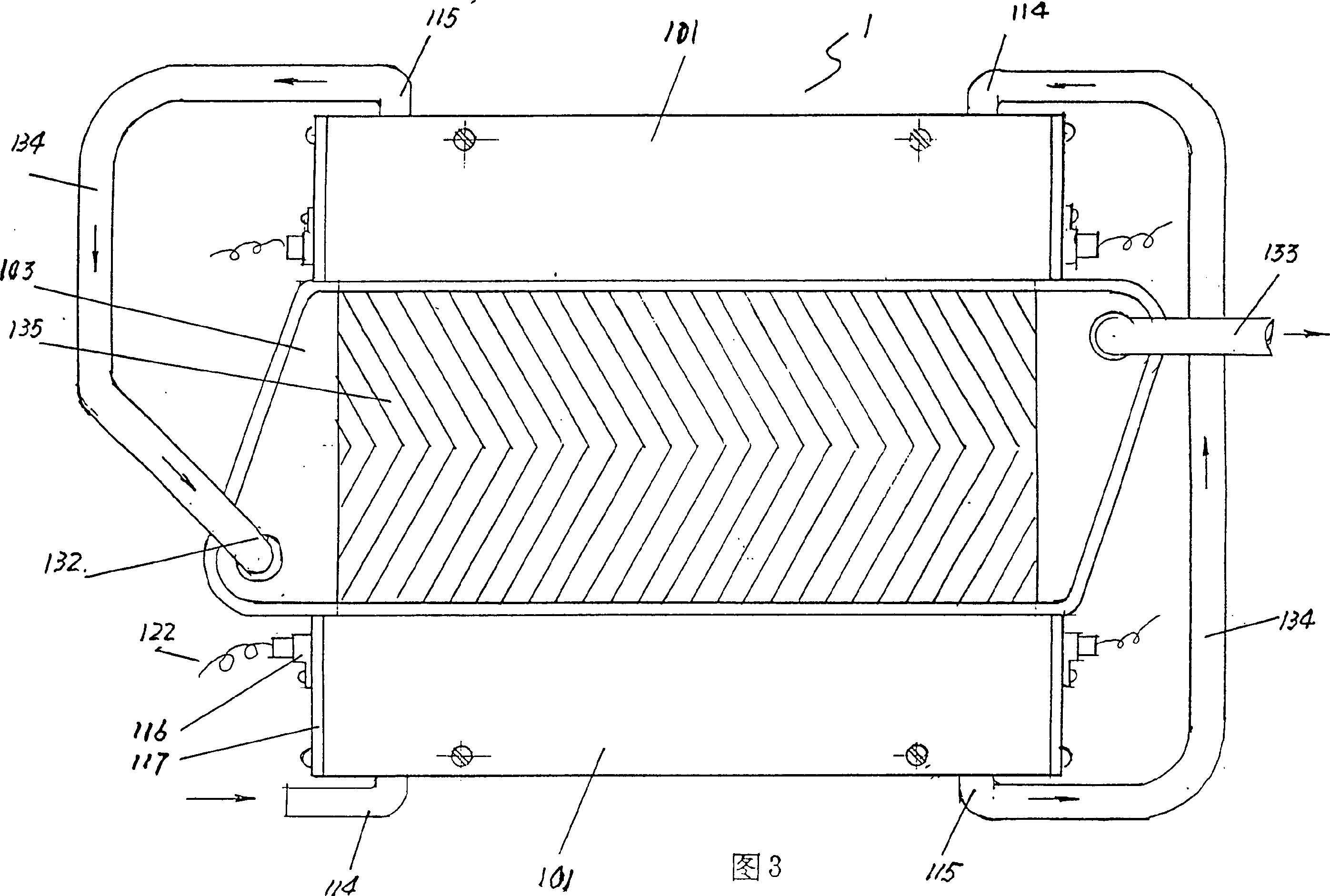

[0071] The structure of the 18KW photoelectric heating unit manufactured according to the above principle is as follows: it consists of two rows of photoelectric heating units (each 15 units), each with a heat exchanger between the upper and lower groups, and the circulating water is reflected by the lower row. The internal cavity flows to the upper reflector internal cavity and then flows through the heat exchanger. The heat medium heats up by 25°C, and the flow rate is 526 liters / hour. According to the heating standard in Beijing, the average indoor temperature is 18°C, and the minimum outdoor temperature is -16°C. The area that can be heated 306 square meters.

[0072] Performance comparison between photoelectric heating host and American regenerative electric boiler

[0073] the power

KW

heat up

25°C

flow

L / hour

Heating area

Annual operating fee

Yuan / M 2

3

electric h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap