Single-driving-source push-pull composite ultrahigh-pressure coring device and grabbing and loosening method

A coring device, source push-pull technology, applied in the direction of extracting the undisturbed core device, earth cube drilling and mining, etc., can solve the problem of large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

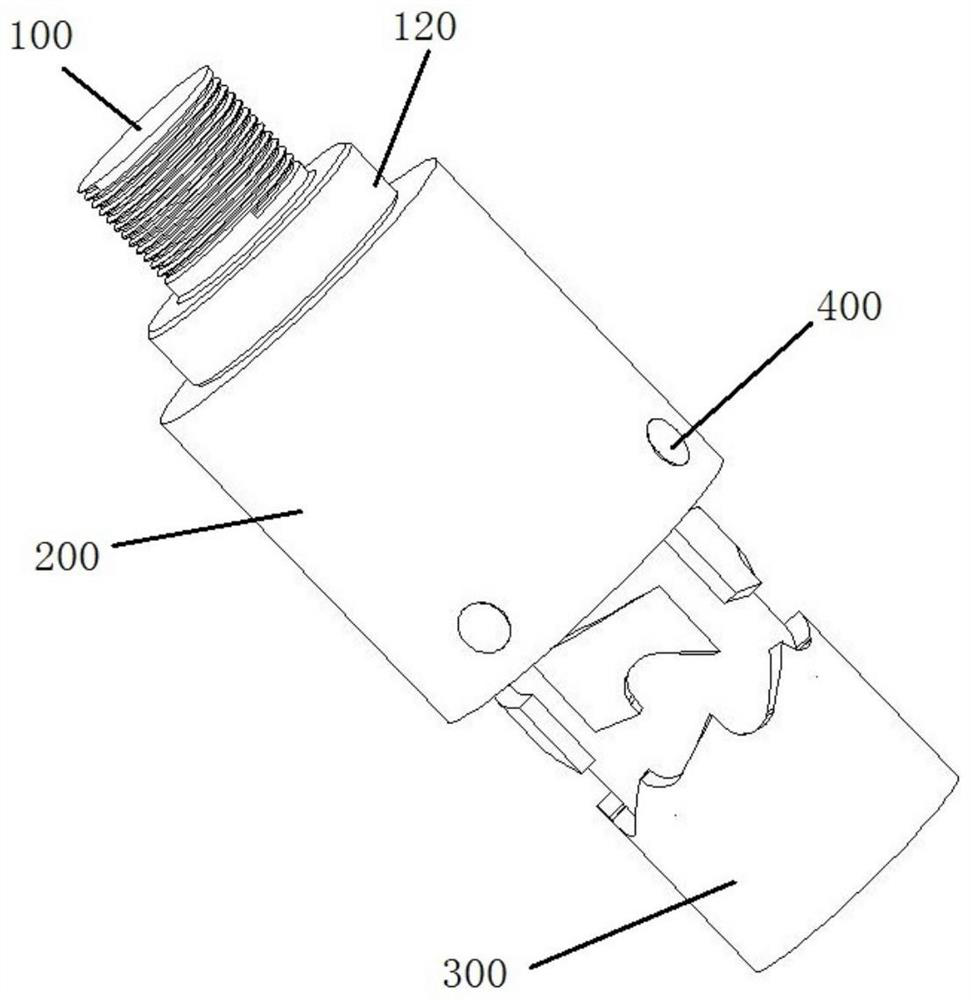

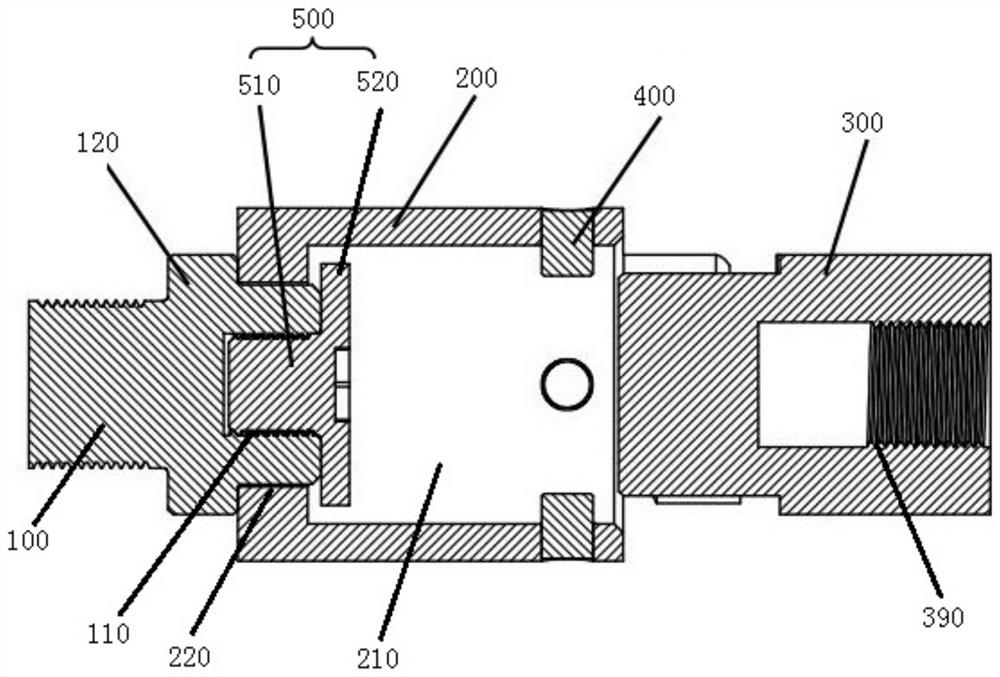

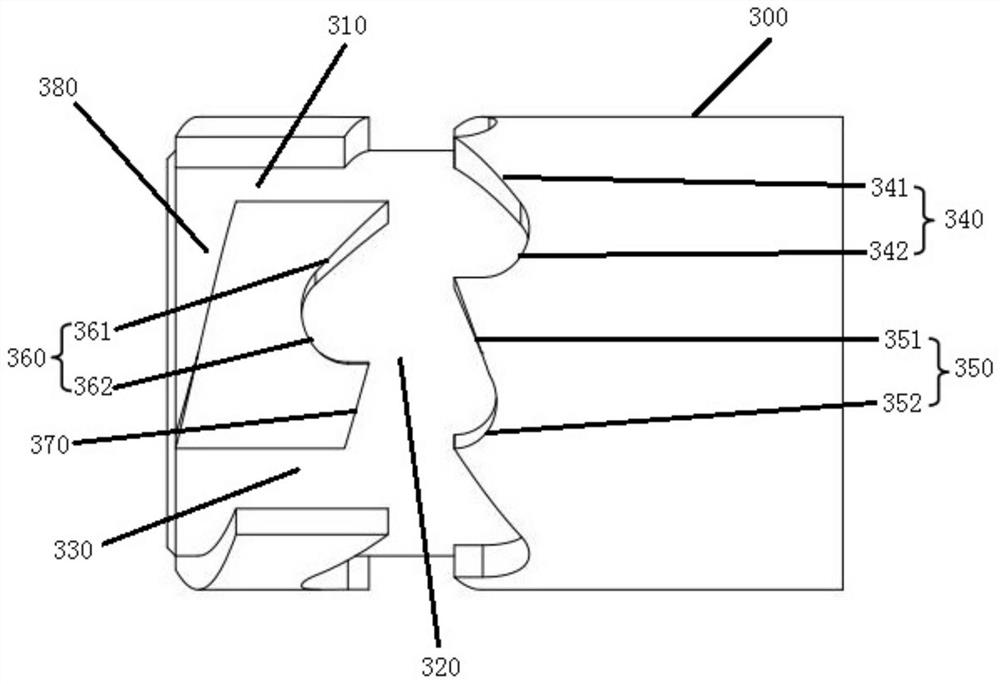

[0038] like Figure 1 to Figure 7 As shown, a single driving source push-pull compound ultra-high pressure coring device in a preferred embodiment of the present invention includes a connecting head 1, a movable head 2 and a fixed head 3, the connecting head 1 is used to connect with the active grasping part, and the fixed head 3 Used to connect with the grasped parts, the movable head 2 is rotatably set on the connecting head 1, and the movable head 2 is provided with at least two pins 4 evenly distributed in the circumferential direction, and the fixed head 3 is provided with the number and the pins The number of pins 4 is equal to the transmission unit, and each transmission unit is evenly spaced along the circumferential direction of the fixed head 3. The transmission unit includes an entry groove 310, a moving groove 320 and an exit groove 330 located on the side wall of the fixed head 3, and the entry groove 310 and the exit groove 330. The exit grooves 330 are arranged ...

Embodiment 2

[0047] This embodiment provides a method that can automatically grab and loosen, including:

[0048] The connecting head 100 is fixedly connected with the manipulator, and the movable head 200 is rotatably set on the connecting head 100. The movable head 200 has at least two pins 400 evenly spaced in the circumferential direction, and the fixed head 300 is connected to the grasped piece. The fixed head 300 has transmission units equal in number to the pins. The transmission unit includes an entry groove 310, a moving groove 320, and an exit groove 330 arranged on the outer wall of the fixed head 300. The entry groove 310 and the exit groove 330 are arranged at intervals and are self-fixing. One end of the head 300 extends along the axial direction of the fixed head 300. The moving groove 320 is located between the entering groove 310 and the moving groove 330 and communicates with the entering groove 310 and the exiting groove 330. The two side walls of the moving groove 320 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com