Welding process parameter issuing control device based on array passive potential

A welding process and control device technology, applied in the field of welding process parameter release control device based on array passive potential, can solve the problems of large resistance error, small current and voltage range, etc., so as to reduce the problem of uncontrollable execution and improve reliability. The effect of stability of sex and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

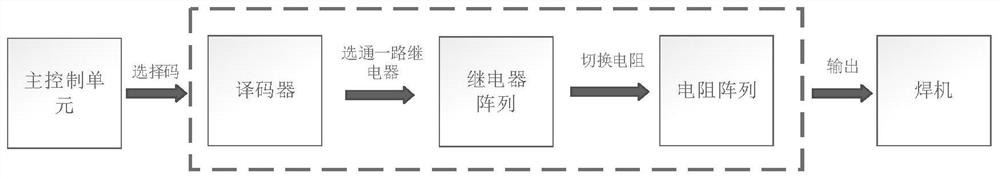

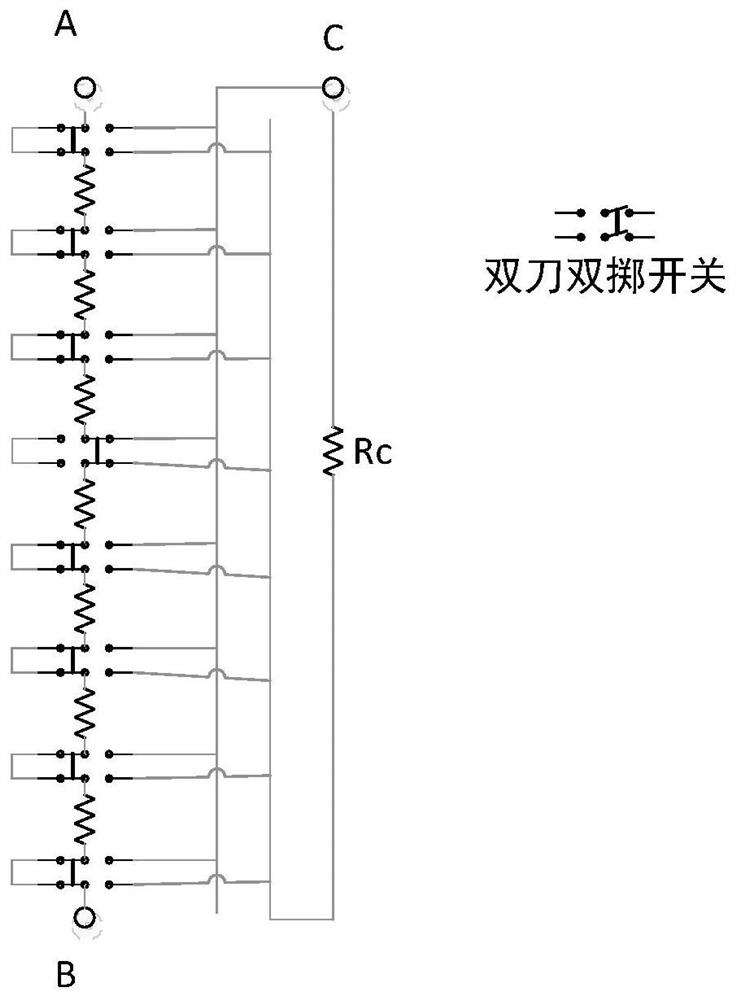

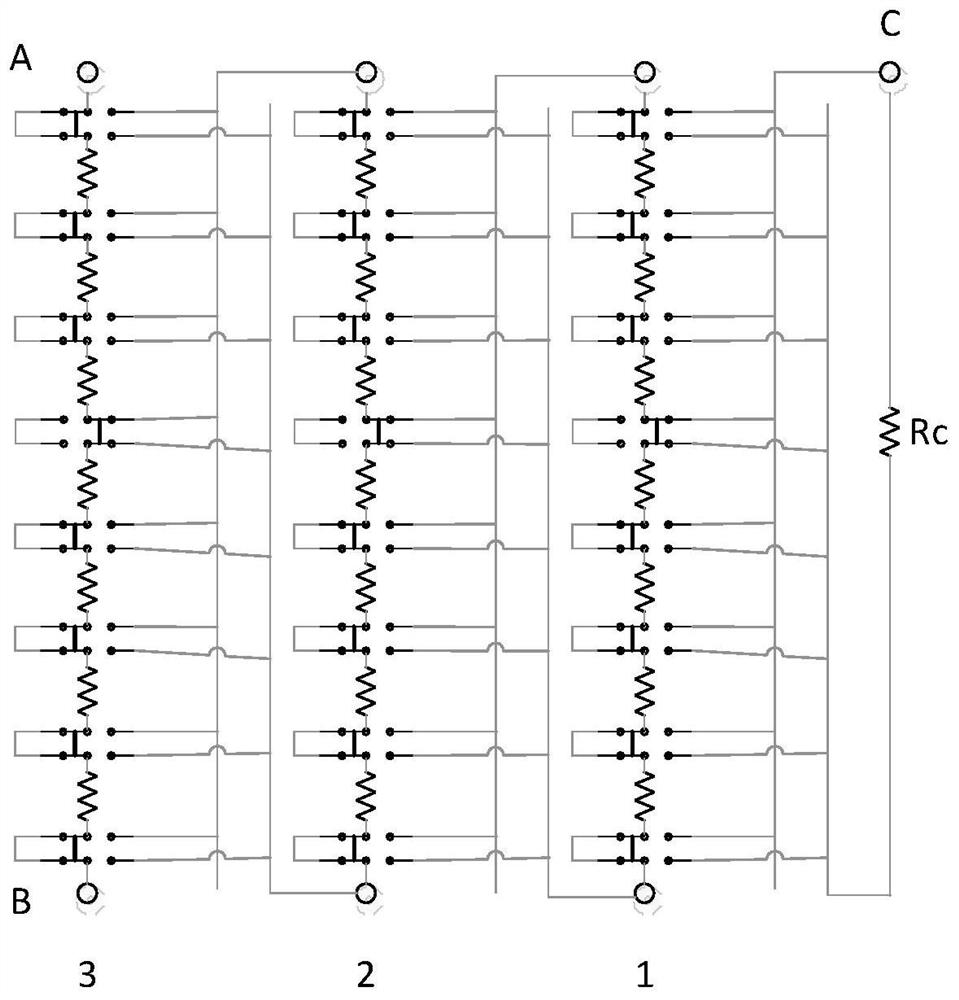

[0014] The invention relates to a control device for automatically issuing process parameters for a welding machine with a remote control box interface. The whole device includes two core modules, the main control unit and the potential adjustment unit. The control device realizes the communication between the main control unit module and the upper computer through the network interface, and receives the preset parameter values from the upper computer, and at the same time, the main control unit outputs the signal to drive the potential adjustment unit to realize the automatic delivery of welding process parameters. The potential adjustment unit is composed of a relay, a relay-resistor array, and a potential output interface. The core principle of the whole device is that according to the output value of the main control chip port of the lower computer, the decoder selectively connects a specific relay, thereby connecting different impedance resistors, and realizes digital a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com