Backward centrifugal impeller and backward centrifugal ventilator comprising same

A centrifugal impeller and rear disc technology, which is applied in mechanical equipment, radial flow pumps, machines/engines, etc., can solve the problems of reduced flow at the impeller outlet, improve reliability and life, improve outlet flow and aerodynamic efficiency, and improve The effect of effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

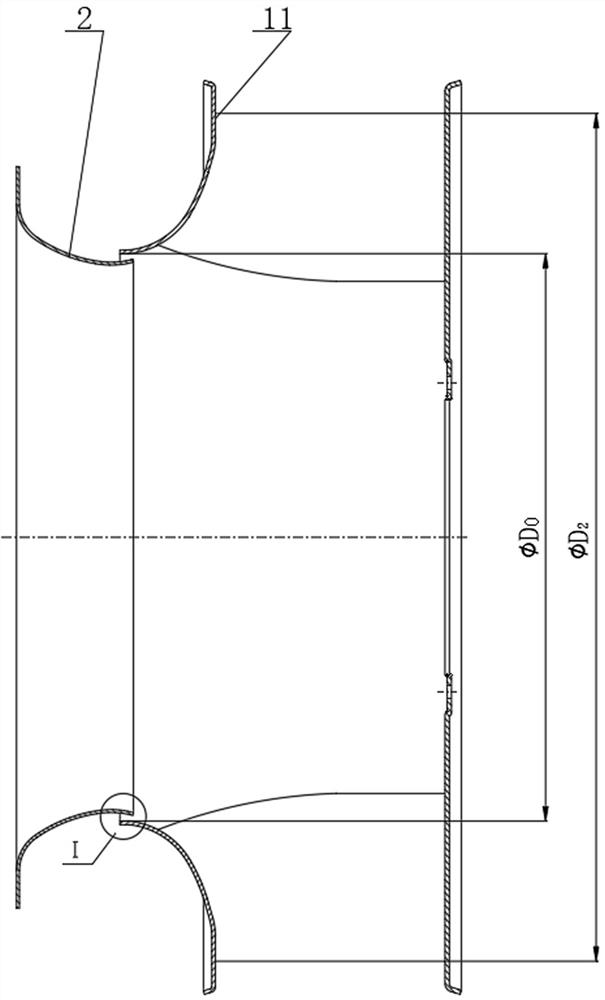

[0023] see Figure 3-Figure 5 , the present embodiment proposes a backward centrifugal impeller, including a rear disk 13, a front disk 12, and a plurality of blades 11 arranged between the rear disk 13 and the front disk 12. The front end of the inner ring of the front disk 12 is provided with an arc-shaped Lan Duan.

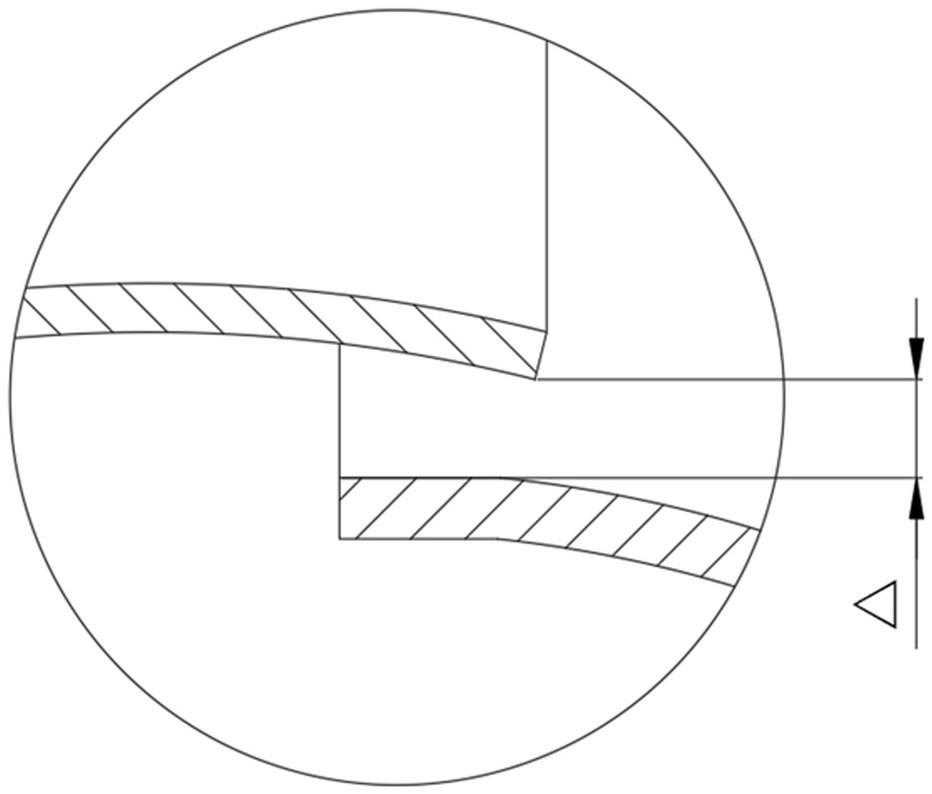

[0024] Specifically, the arc-shaped flange section in this embodiment includes a flange plane section ab, an arc-shaped constriction section bc, and a straight cylinder section cd. The flange plane section ab is an annular plane perpendicular to the axis of the impeller, and the straight cylinder section cd is The centerline coincides with the axis of the impeller in the shape of a cylinder, the arc-shaped contraction section bc has an arc-shaped cross-section along the axial direction, and its convex surface is inward, and the cross-sectional shape is arc-shaped, elliptical or other curved shapes. In this embodiment The circular arc shape is preferably used i...

Embodiment 2

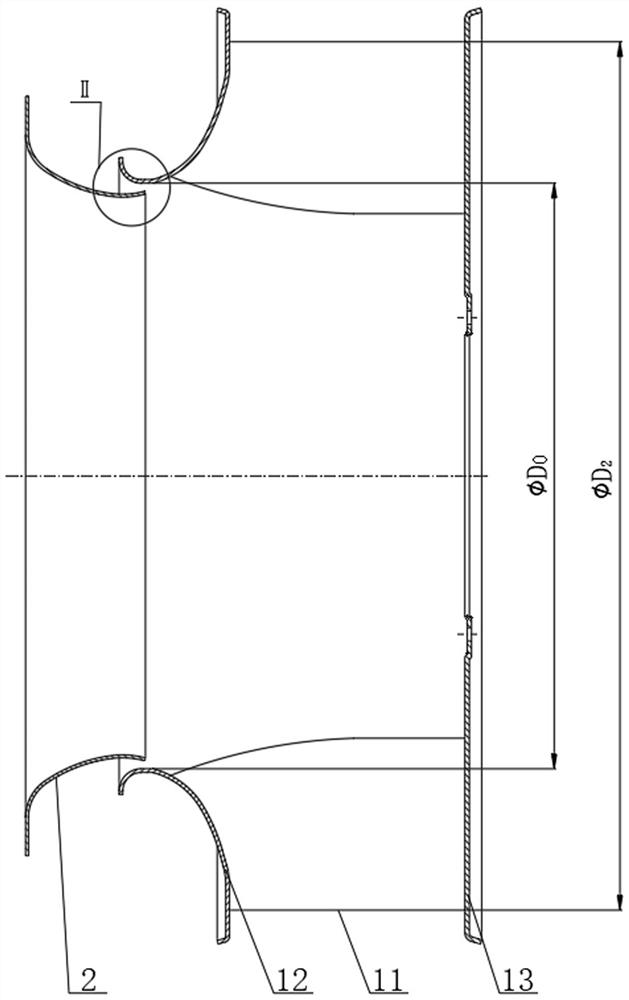

[0027] This embodiment proposes a backward centrifugal impeller, including a rear disc 13, a front disc 12 and a number of blades 11 arranged between the rear disc 13 and the front disc 12, and the front end of the inner ring of the front disc 12 is provided with an arc-shaped flange part.

[0028] Specifically, the arc-shaped flange section in this embodiment includes a flange plane section ab, an arc-shaped constriction section bc, and a straight cylinder section cd. The flange plane section ab is an annular plane perpendicular to the axis of the impeller, and the straight cylinder section cd It is in the shape of a cylinder whose center line coincides with the axis of the impeller. The arc-shaped constriction section bc has an arc-shaped cross-section along the axial direction, and its convex surface is inward. The cross-sectional shape is arc-shaped. The backward centrifugal impeller in this application is applied On the centrifugal fan, when assembling, the outlet end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com