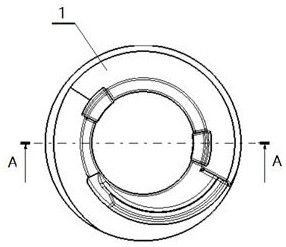

Upper mounting seat of rear spiral spring

A technology of rear helix and mounting seat, applied in the direction of the spring, etc., to increase the overall stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below with reference to the accompanying drawings.

[0027] see Figure 2 to Figure 6 A mounting seat for the rear coil spring shown in the figure includes a rubber body 1 and a metal ring frame 2) disposed therein. A rear coil spring contact part 14 is arranged under the rubber body; the metal ring frame 2 has a ring thickness 22 and a ring width 23; the metal ring frame 2 and the rubber body 1 are integrated into a whole by vulcanization, and the metal ring frame 2 The distance from the bottom of the rubber body 1 is 2 / 3 of the thickness 12 of the body. When the whole vehicle is subjected to a small shock, the mounting seat on the rear coil spring can be compressed and deformed and absorb energy to meet the requirements of vibration reduction and noise reduction; when the whole vehicle is subjected to a large shock, the rear coil spring has enough force in the process of transmitting force. Stiffness guarantees durab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com