Checking fixture, inspection method of turbocharger middle casing

A technology of checking tools and measuring rods, which is applied in the direction of mechanical clearance measurement, instruments, measuring devices, etc., can solve problems such as low efficiency and inaccurate measurement, simplify inspection steps, improve measurement accuracy, and solve repeatability and reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

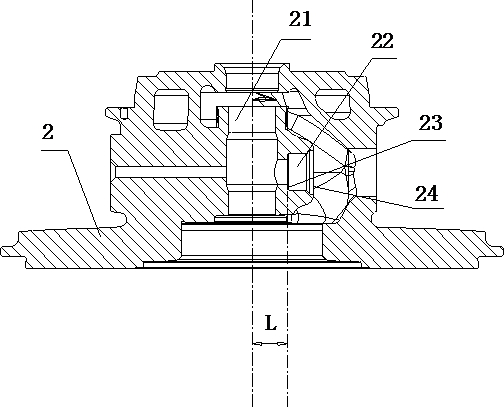

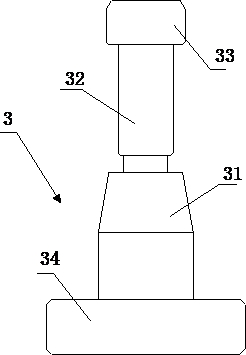

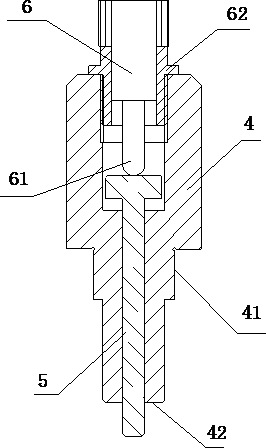

[0030] Such as Figure 1 to Figure 5 As shown, a checker includes a reference shaft 3, which is suitable for being inserted into the bearing hole 21 of the middle shell 2. The reference shaft 3 is provided with a centering mechanism and a measuring part 32. The centering mechanism is suitable for bearing The hole 21 is matched so that the centerline of the reference shaft 3 coincides with the centerline of the bearing hole 21; the center of the outer diameter of the measuring part 32 coincides with the centerline of the reference shaft 3, and the measuring part 32 is located on the side of the oil inlet hole 22; The measuring tool is suitable for matching with the inner step surface 23 of the oil inlet hole 22. The measuring rod 5 of the dial gauge measuring tool passes through the oil inlet hole 22 and abuts against the outer diameter of the measuring part 32 perpendicularly, so that the measuring The rod 5 is displaced in the dial indicator measuring tool, and the dial indic...

Embodiment 2

[0050] Such as Figure 5 As shown, a method for detecting the middle case 2 of a turbocharger adopts the inspection tool described in Embodiment 1, including: positioning the middle case 2: inserting the reference shaft 3 from the bearing hole 21 of the middle case 2, so that the reference shaft 3 The centerline of the centerline coincides with the centerline of the bearing hole 21 of the middle shell 2; when the reference shaft 3 is manufactured, ensure that the tapered part 31, the measuring part 32 and the limit part 33 are all on the same axial centerline, and then ensure that the measuring part 32 The center of the outer diameter circle is also on the axis; then the tapered portion 31 and the stop portion 33 cooperate with the bearing hole 21 to ensure that the axis of the reference shaft 3 coincides with the axis of the bearing hole 21.

[0051] Calibration of the dial indicator measuring tool: insert the measuring rod 5 of the dial indicator measuring tool into the cali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com