Experimental device for friction loss between contact wire and pantograph of high-strength high-speed rail

A technology of contact wire and friction loss, which is applied in the field of experimental equipment for friction loss between high-strength high-speed iron contact wire and pantograph, can solve the problems of pantograph constraints, etc. The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

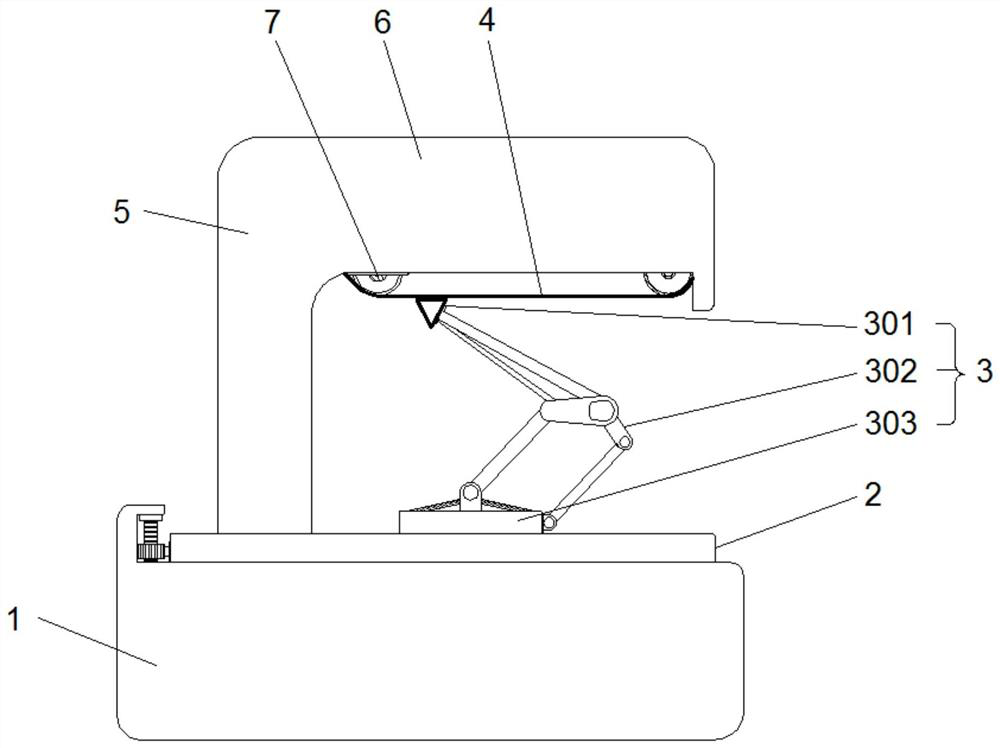

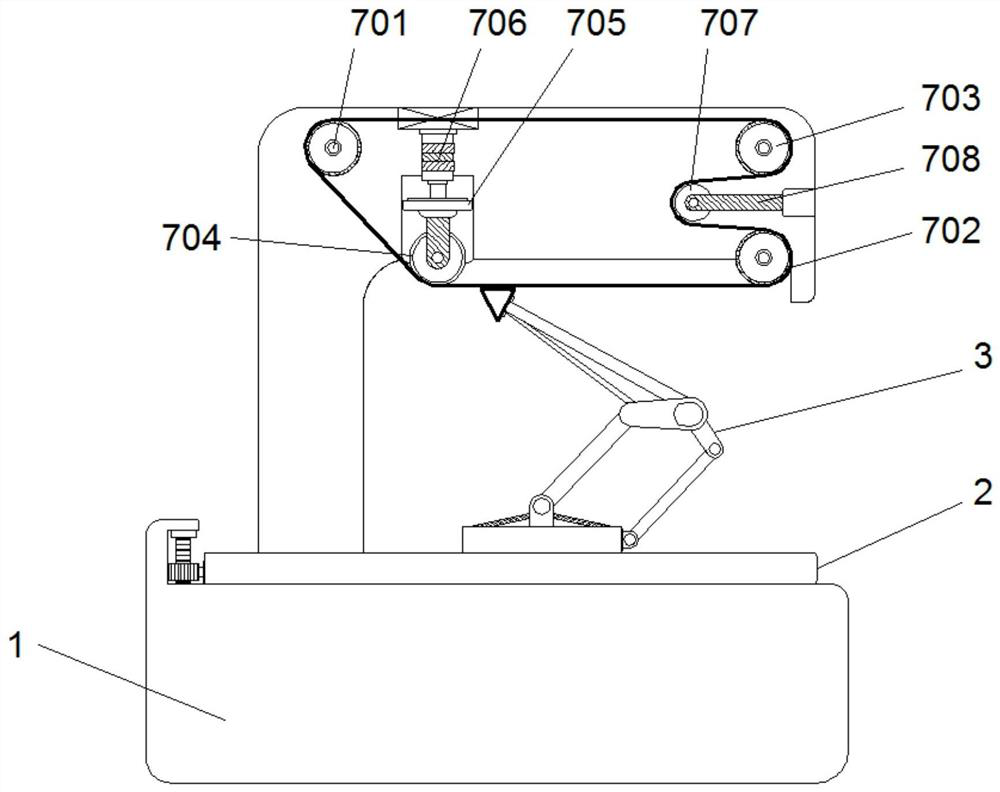

[0030] see Figures 1 to 4, in the embodiment of the present invention, the experimental device for friction loss between the high-strength high-speed rail contact wire and the pantograph includes a base 1, and the upper end of the base 1 is provided with a test platform 2 for placing the pantograph assembly 3, The base 303 of the pantograph assembly 3 is fixedly clamped on the upper end surface of the experimental platform 2, the sliding plate 301 of the pantograph assembly 3 is fixed on the upper end of the base 303 through the support arm 302, and the upper end of the sliding plate 301 is in contact with the experimental lead 4, The experimental lead 4 is installed on the wire guide assembly 7 opposite to the pantograph assembly 3 in the rotation transmission direction, the wire guide assembly 7 is installed in the top plate 6 on the base 1, and the top plate 6 is fixed by the stand 5 Set on the base 1, the experimental lead 4 rotates at a high speed under the drive of the ...

Embodiment 2

[0039] see Figures 5 to 7 , on the basis of Example 1, the embodiment of the present invention further improves the experimental device for the friction loss between the high-strength high-speed rail contact wire and the pantograph to simulate the travel of the high-speed rail during operation, so that the pantograph assembly 3 is subjected to simulated travel. The bumps and vibrations on the route are as follows:

[0040] The machine base 1 is also provided with a bumpy vibration assembly that acts synchronously with the wire guide assembly 7 and simulates bumps and vibrations encountered by the high-speed rail. The pantograph assembly 3 is fixedly clamped on the end surface of the movable plate 203, the lower end of the movable plate 203 is provided with a contact plate 204 made of elastic material, and a push box 23 is arranged under the contact plate 204, and the push box 23 can be lifted and lowered. Below the contact plate 204, the push box 23 is spaced apart from the ...

Embodiment 3

[0045] On the basis of Example 1, the embodiment of the present invention upgrades the function of the experimental device for friction loss between the high-strength high-speed rail contact wire and the pantograph, specifically:

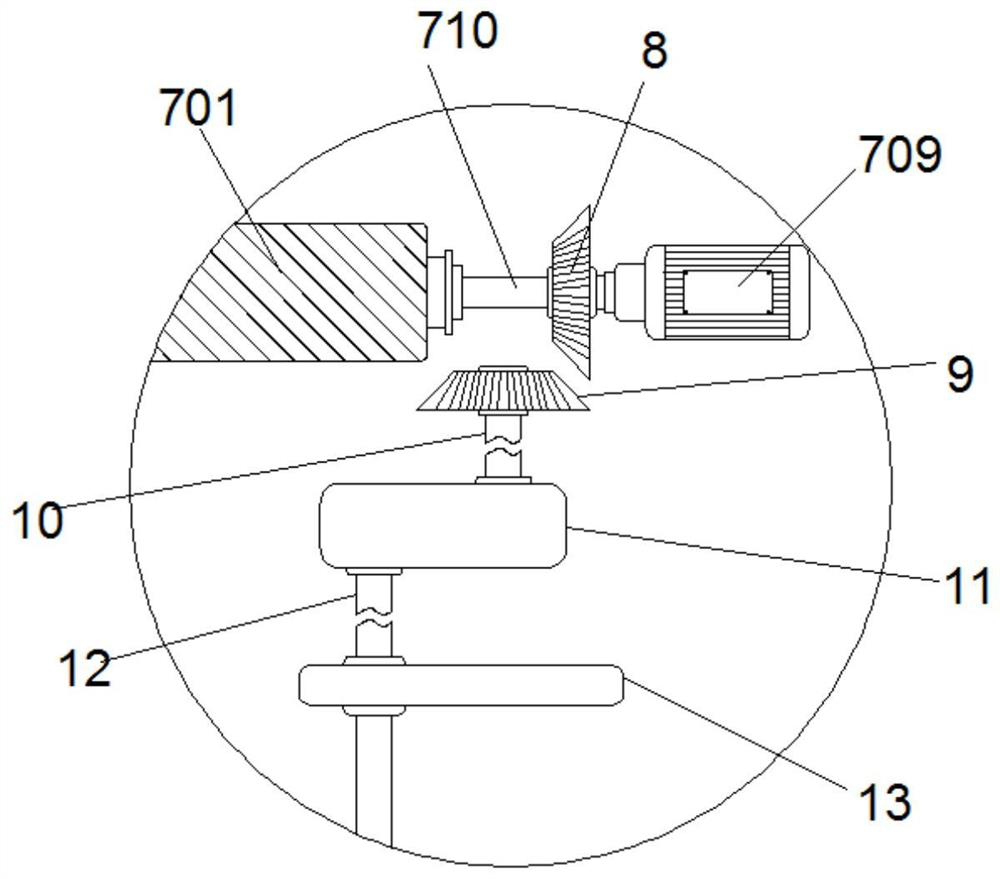

[0046] The first rotating shaft 710 in the wire guide assembly 7 is also installed with a data acquisition device, and the data acquisition device is a rotational speed detector, a mileage detector, a timer, etc. , to obtain the friction speed and total mileage of the pantograph assembly 3 and the experimental lead 4, so as to provide necessary data parameters for the subsequent friction loss experiments and ensure the accurate development of the experiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com