Fire extinguishing pipe assembly, battery heat management device, battery system and electric vehicle

A technology of battery thermal management and fire extinguishing tubes, which is applied to secondary batteries, exhaust plug devices, battery pack components, etc., can solve problems such as flame generation, safety accidents, power battery thermal failure, etc., and reduce safety accidents The chances of reducing the chances of flames continuing to spread and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a fire extinguishing pipe assembly, which is applied to the battery thermal management device, and can quickly extinguish the fire at the initial stage of the flame generated by the power battery due to thermal failure, thereby reducing the probability of safety accidents, so that the battery thermal management device and the battery The system can have higher security.

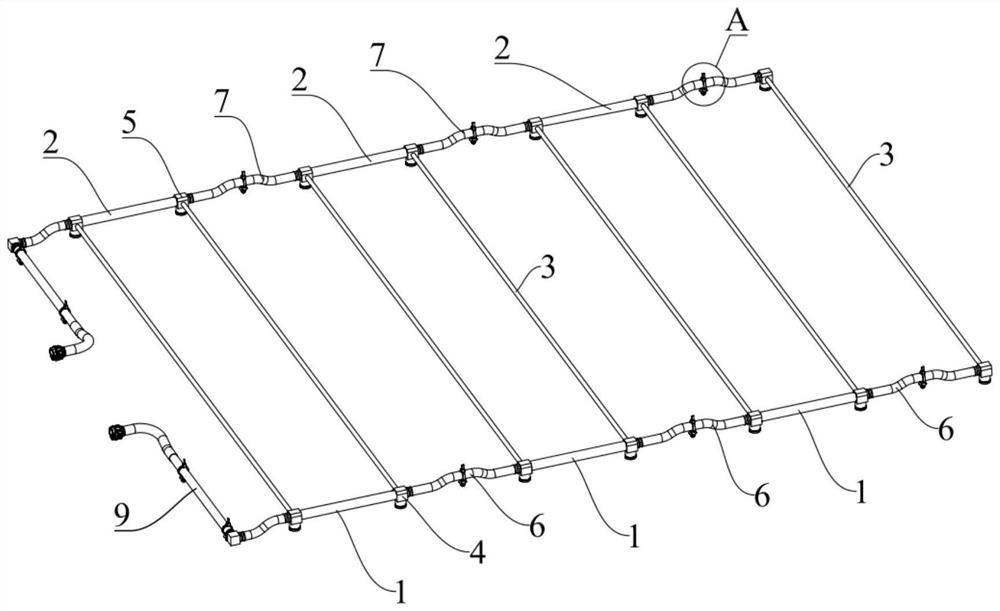

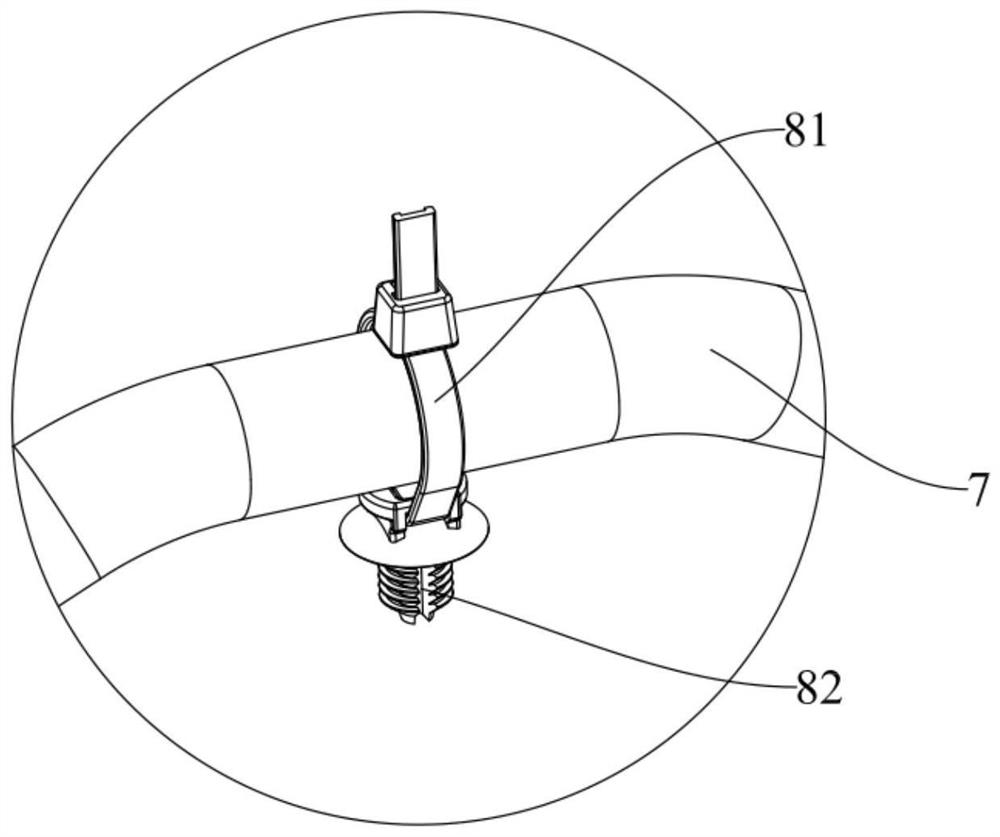

[0041] Such as figure 1 As shown, the fire extinguishing pipe assembly includes a first main pipe 1, a second main pipe 2 and a branch pipe 3.

[0042] Wherein, the first main pipe 1 is connected to the outlet of the heat dissipation module of the battery thermal management device, so that the heat dissipation module can deliver the cooled coolant to the first main pipe 1 . In some embodiments, the first main pipe 1 is directly connected to the outlet of the cooling module; in other embodiments, the first main pipe 1 is indirectly connected to the outlet of the cooling module ...

Embodiment 2

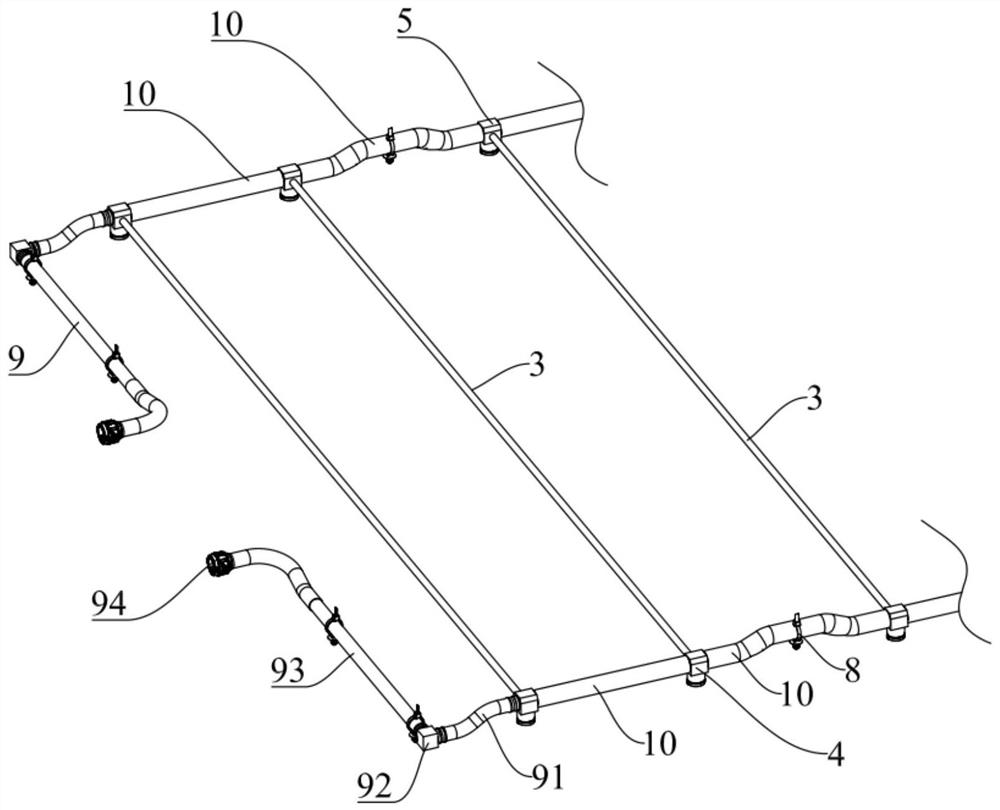

[0066] This embodiment also provides a battery heat management device, which can be used to cool down the battery module in the battery system, and can also extinguish the battery module when the battery module generates flames.

[0067] Among them, such as Image 6 As shown, the battery thermal management device includes a liquid cooling plate 100, a heat dissipation module (not shown) and the fire extinguishing pipe assembly in the first embodiment. One end of the liquid cooling plate 100 is connected and communicated with the first main pipe 1 , so that the cooling liquid in the first main pipe 1 can also enter the liquid cooling plate 100 . The other end of the liquid cooling plate 100 is connected and communicated with the second main pipe 2 , so that the cooling liquid in the liquid cooling plate 100 can enter the second main pipe 2 . The first main pipe 1 communicates with the outlet of the cooling module, and the second main pipe 2 communicates with the inlet of the c...

Embodiment 3

[0069] This embodiment provides a battery system, which is applied to new energy vehicles and has high safety and reliability in use.

[0070] Among them, such as Figure 7 with Figure 8 As shown, the battery system includes a battery module 200 and the battery thermal management device in the second embodiment. The battery module 200 has an explosion-proof valve 2011 , specifically, the battery module 200 includes a plurality of cells 201 , each cell 201 has an explosion-proof valve 2011 , and the explosion-proof valve 2011 is located directly above the cell 201 . The branch pipe 3 of the fire extinguishing pipe assembly is located directly above the explosion-proof valve 2011. Preferably, the distance between the branch pipe 3 and the explosion-proof valve 2011 is 2-5 mm, and the injection surface of the explosion-proof valve 2011 is the top surface, so that when the explosion-proof valve 2011 sprays high-temperature and high-pressure gas, the upper branch pipe 3 can be b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com