Energy-saving heat dissipation type high-low voltage power cabinet

A high-voltage and low-voltage power cabinet technology, which is applied in the direction of electrical components, substation/power distribution device casing, substation/switch layout details, etc., can solve the problems of low heat dissipation efficiency, poor heat dissipation effect, waste of energy, etc., and achieve faster cooling speed, The effect of increasing the heat conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

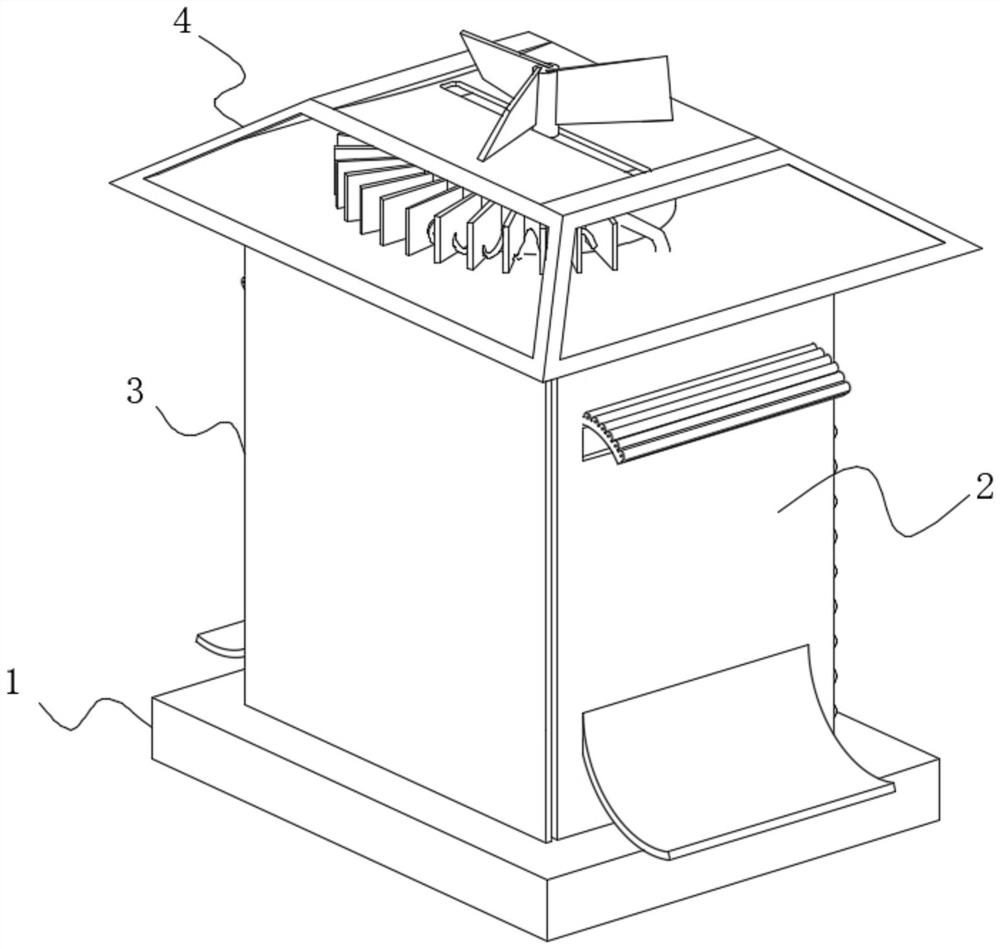

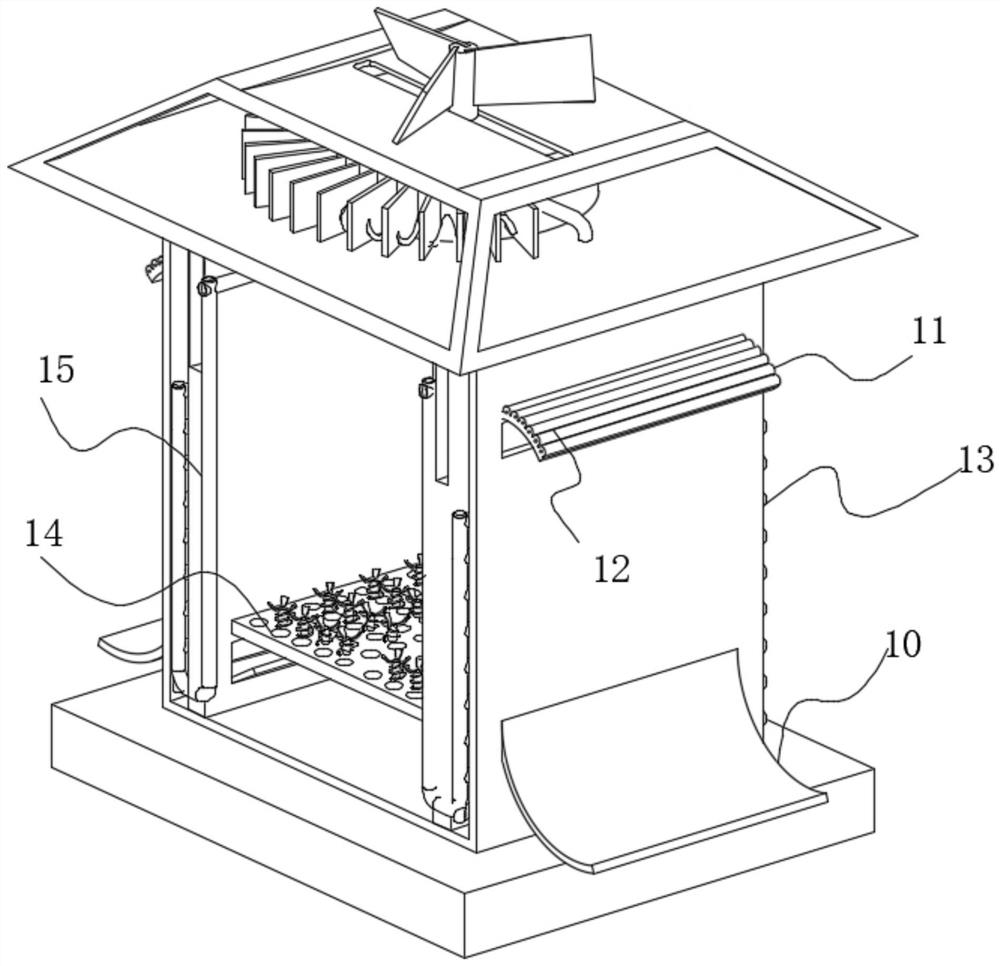

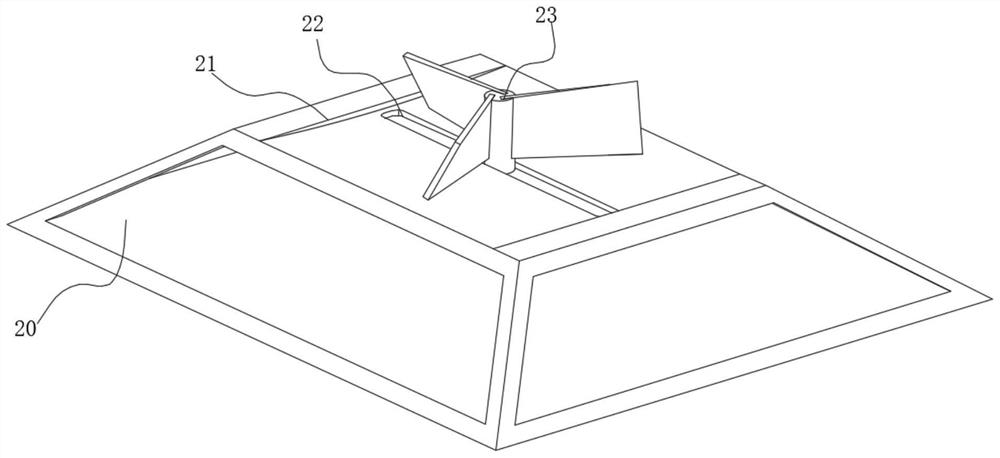

[0023] use Figure 1-Figure 7 An energy-saving and heat-dissipating high-voltage and low-voltage power cabinet according to an embodiment of the present invention will be described as follows.

[0024] Such as Figure 1-Figure 7 As shown, an energy-saving and heat-dissipating high and low voltage power cabinet according to the present invention includes a bottom plate 1; The upper surface of the cabinet body 2 is fixedly connected with a sunshade roof 4, the side of the cabinet body 2 is fixedly connected with an arc-shaped plate 10, the arc-shaped plate 10 is located outside the cabinet body 2, and the top of the arc-shaped plate 10 is provided with a baffle plate 11. The outer surface is rotatably connected to the inner surface of the cabinet body 2, the upper surface of the baffle plate 11 is fixedly connected with a spoiler 12, and the back of the spoiler 12 is provided with a liquid cooling mechanism 13, and the outer surface of the liquid cooling mechanism 13 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com