Gardenia blue pigment and production method for same

A technology of gardenia blue pigment and manufacturing method, which is applied in the direction of chemical instruments and methods, biochemical equipment and methods, enzymes, etc., can solve the problems of unsatisfactory color tone, unmanufacturability, reduction of spirulina pigment brightness, etc., and achieve good The effects of color tone coloring, high safety, and easy manufacturing management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2-1~2-5

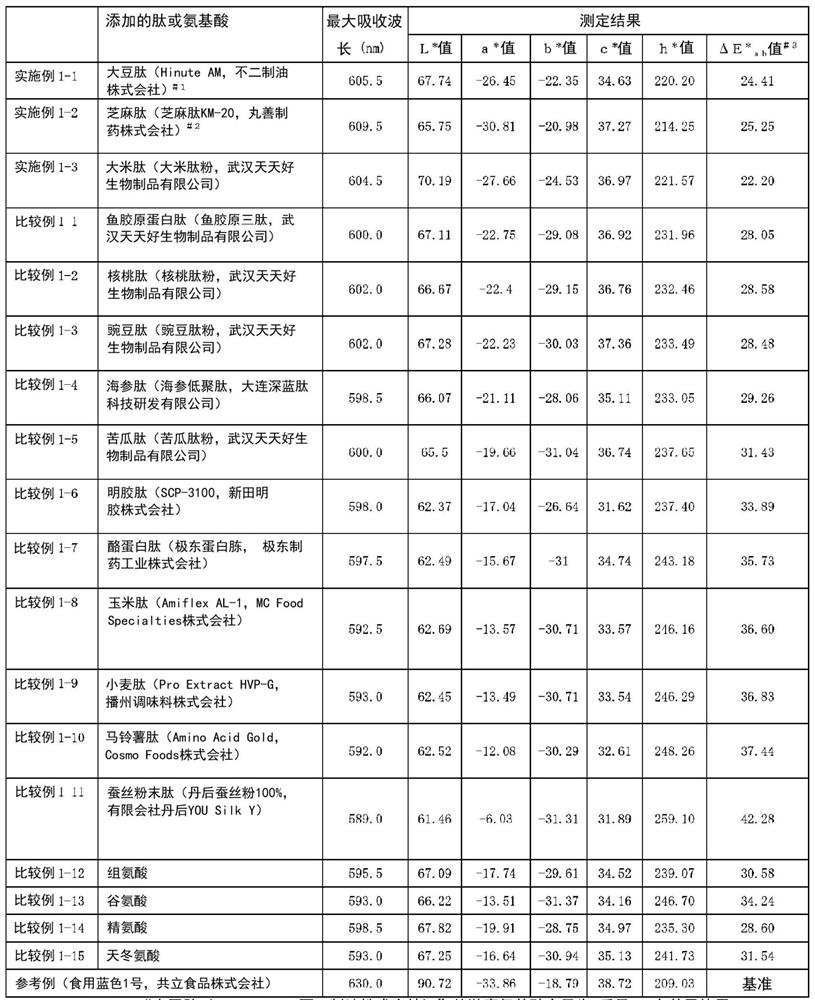

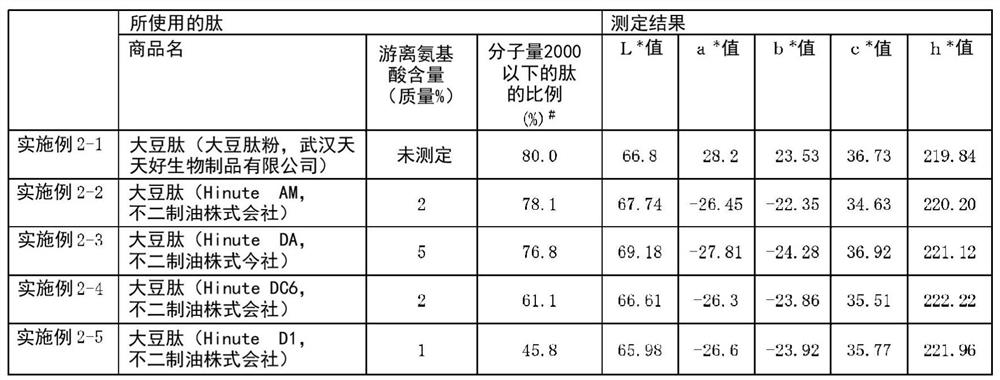

[0159] Gardenia blue dyes were produced in the same manner as in Test Example 1 above, except that the soybean peptides shown in Table 3 were used for the reaction under the condition of not supplying oxygen.

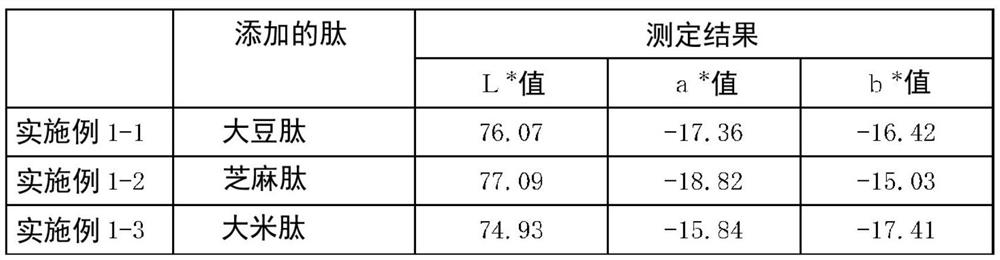

[0160] 2. Determination of hue of gardenia blue pigment

[0161] The hue of the obtained gardenia blue pigment was measured under the same conditions as in Test Example 1 above. The obtained results are shown in Table 3. From this result, it was confirmed that when the predetermined peptide and genipin were reacted under the condition of not supplying air and then reacted under the condition of supplying air, the lower the free amino acid content of the peptide used, the more panacea could be obtained. A gardenia blue pigment with a good tone that suppresses redness.

[0162] [table 3]

[0163]

[0164] #The ratio (%) of peptides with a molecular weight of 2000 or less is a value obtained by calculating the ratio of the peak area of a peptide with a molecular ...

Embodiment 3-1~3-3

[0166] 1. Manufacture of gardenia blue pigment (using a fermenter) (Examples 3-1 to 3-3 and Comparative Example 3-1)

[0167] As the added peptide, soybean peptide (Hinute AM, Fuji Oil Co., Ltd.) was used, and the reaction time under the condition of not supplying oxygen was changed to 0 hour (Comparative Example 3), 4 hours (Example 3-1), The gardenia blue dye was produced by the method similar to the said Experimental Example 1 except 5 hours (Example 3-2) and 22 hours (Example 3-3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com