Auxiliary device for waste gas treatment equipment of rubber production plant

A technology for waste gas treatment equipment and auxiliary devices, applied in the rubber field, can solve the problems of poor cleaning effect of the cleaning mechanism, clogging of filter plates, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

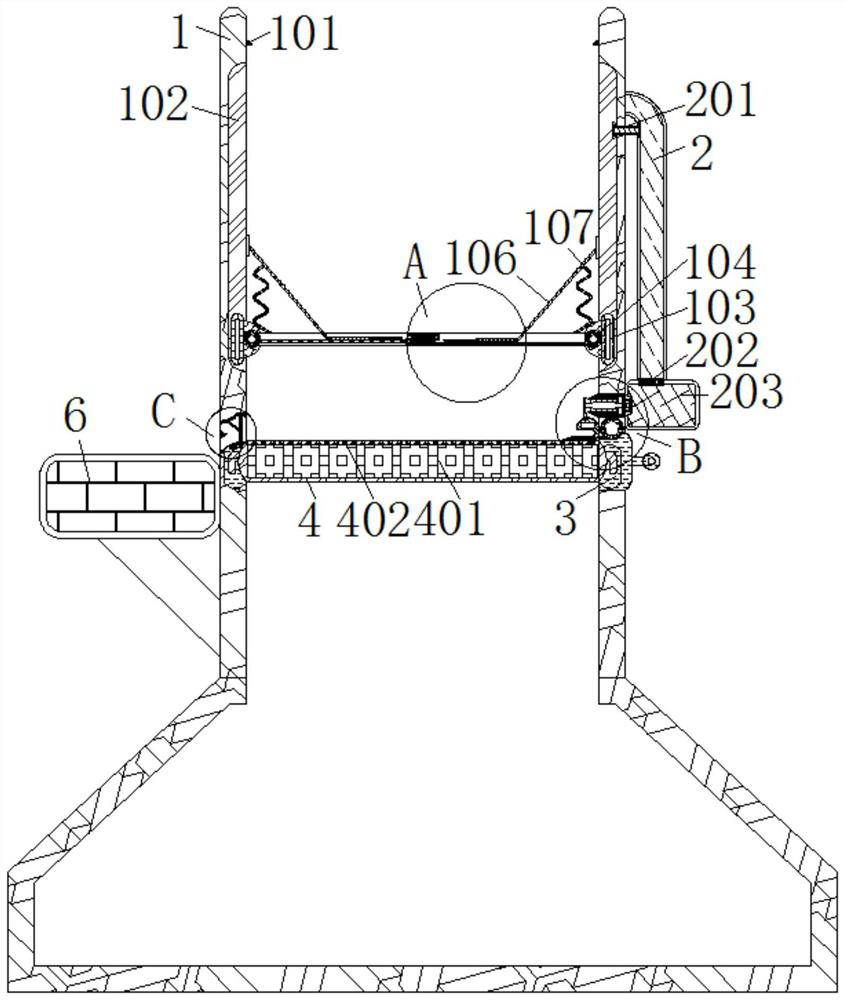

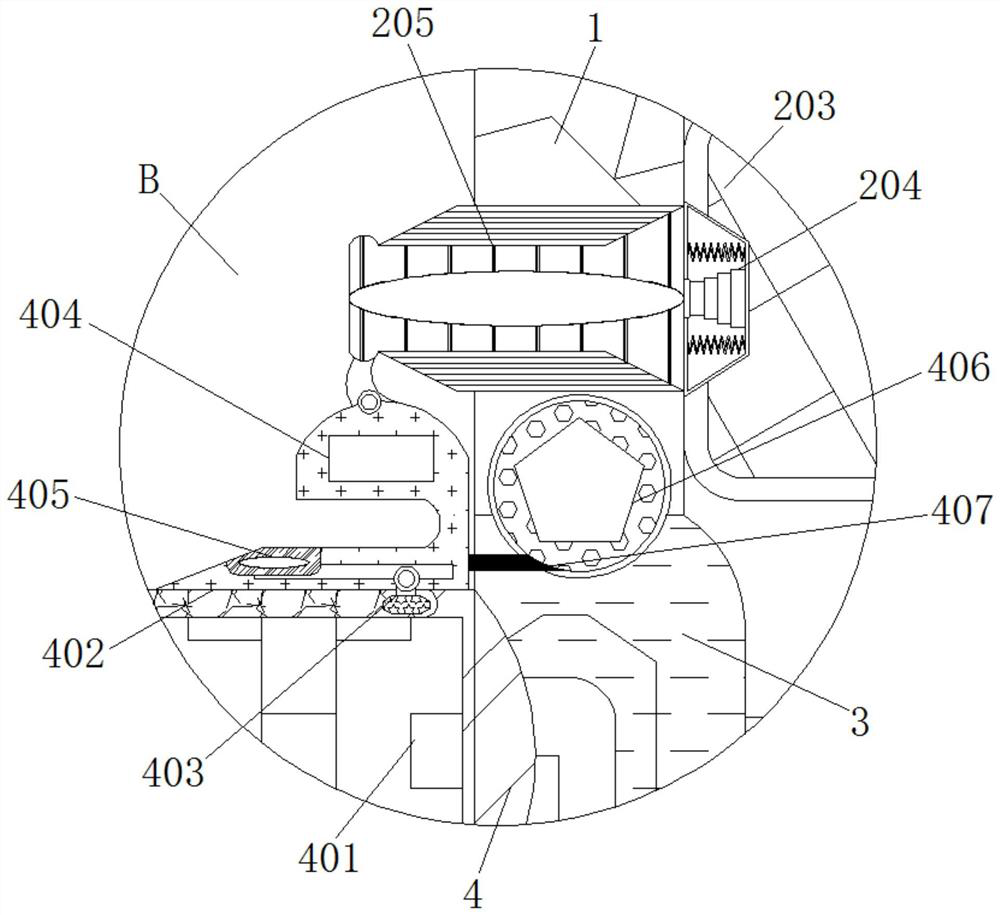

[0022] see Figure 1-4 , an auxiliary device for exhaust gas treatment equipment in rubber production plants, including a passage 1, a flow pipe 2 is fixedly installed on the right side of the passage 1, and an installation block 3 is detachably installed on the left and right sides of the middle of the passage 1, and the installation block 3 A fixed frame 4 is installed detachably on the left side of the slideway 2, a moving block 403 is movably installed on the right side of the inner chamber of the slideway 2 402, a scraper 404 is movably installed on the top of the movable block 403, and a scraper 404 is fixedly installed on the top of the left side of the scraper 404. Magnet 2 405, the middle part of the left side of the channel 1 is provided with a pouring port 5, and the left side of the channel 1 is fixedly equipped with a collecting block 6.

[0023] Working principle: When in use, by setting the scraper 404 and the sealing cover 104, the waste gas produced by the rub...

Embodiment 2

[0025] see Figure 1-4 , an auxiliary device for exhaust gas treatment equipment in rubber production plants, including a passage 1, a flow pipe 2 is fixedly installed on the right side of the passage 1, and an installation block 3 is detachably installed on the left and right sides of the middle of the passage 1, and the installation block 3 The left side of the slideway 402 is detachably installed with a fixed frame 4, and the right side of the inner cavity of the slideway 2 402 is movably installed with a moving block 403, and the top of the moving block 403 is movably installed with a scraper 404, and the top of the left side of the scraper 404 is fixedly installed with a magnet Two 405, the middle part of the left side of the channel 1 is provided with a pouring port 5, and the left side of the channel 1 is fixedly installed with a collection block 6.

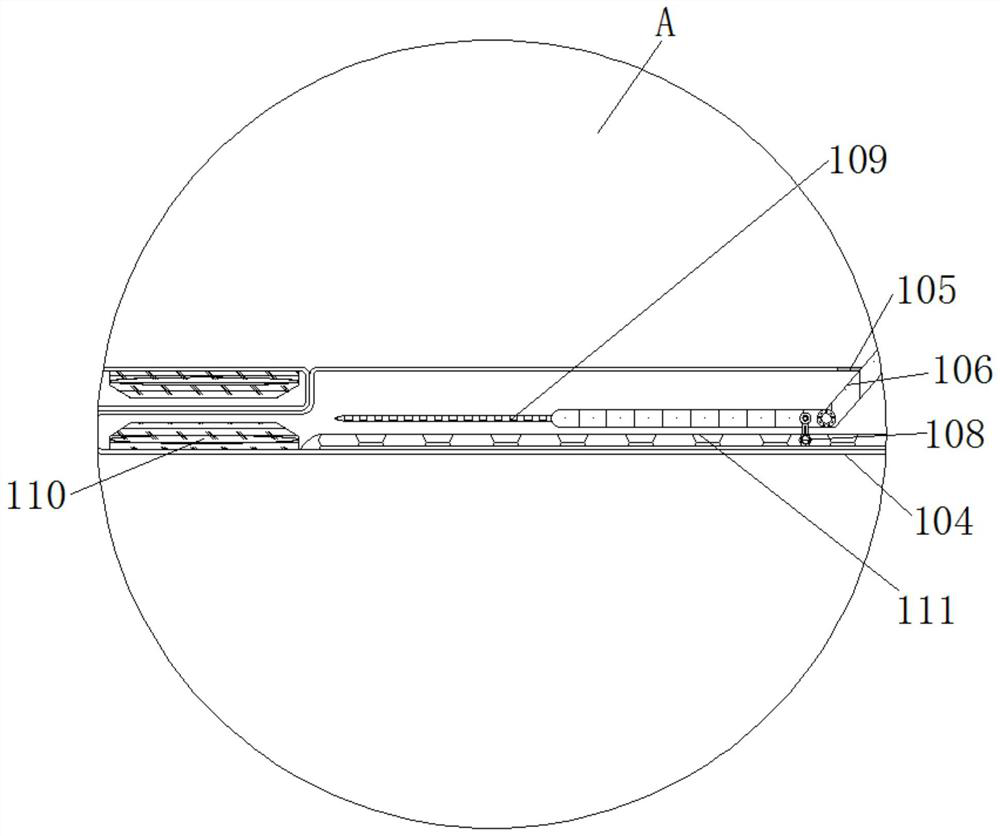

[0026]Wherein, the left and right sides of the top of the passage 1 inner cavity are fixedly equipped with resisting blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com