An embedded device and method for real-time detection of welding quality of keyhole tig welding

An embedded device, real-time detection technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of real-time identification and remote monitoring of difficult welding quality, and achieve the effect of wide application, low cost and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

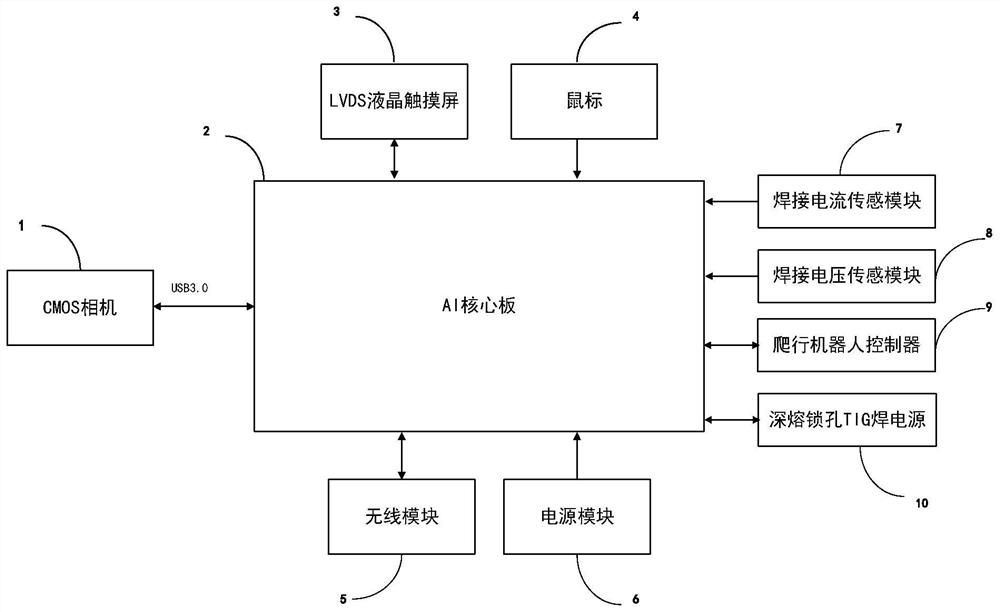

[0062] like figure 1 As shown, the embedded device for real-time detection of keyhole TIG welding welding quality includes:

[0063] CMOS camera, connected to the AI core board, is used to collect the welding scene images of keyhole TIG welding in real time, and transmit the image data to the AI core board; the CMOS camera has the functions of software triggering and exposure time setting, and the exposure time range is within 100us- 50ms, the dynamic range is greater than 60dB, and the frame rate is greater than 60 frames / s;

[0064] The AI core board communicates data with other components of the embedded device, and integrates the real-time detection software package of keyhole TIG welding welding quality; the PCB size of the AI core board is 40mmx55mm, adopts RK1808K wide temperature AI chip, and has a memory of 2GB DDR4 SDRAM, storage is 8GB eMMC 1 channel, equipped with LVDS LCD screen interface, 1 channel Gigabit Ethernet interface, 1 channel USB3.0Host interfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com