Foam forming machine with stable and reliable moving and locking of movable mold

A foam molding machine and mold shifting technology, which is applied in the field of foam machine molding machines, can solve the problem that the transmission stability of the synchronous belt drive assembly cannot be guaranteed, the failure rate of the hydraulic power assembly is high, and the power transmission of the hydraulic power assembly is slow. problems, to ensure the effect of product molding and product quality, to ensure the efficiency of clamping, and to reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

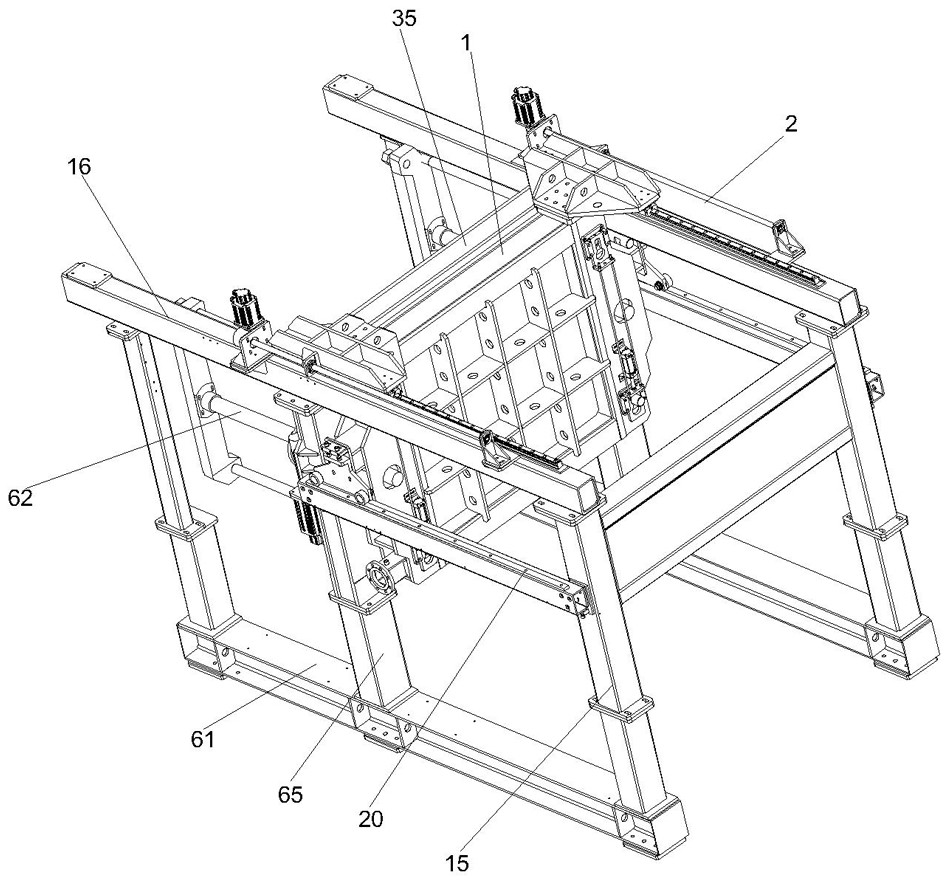

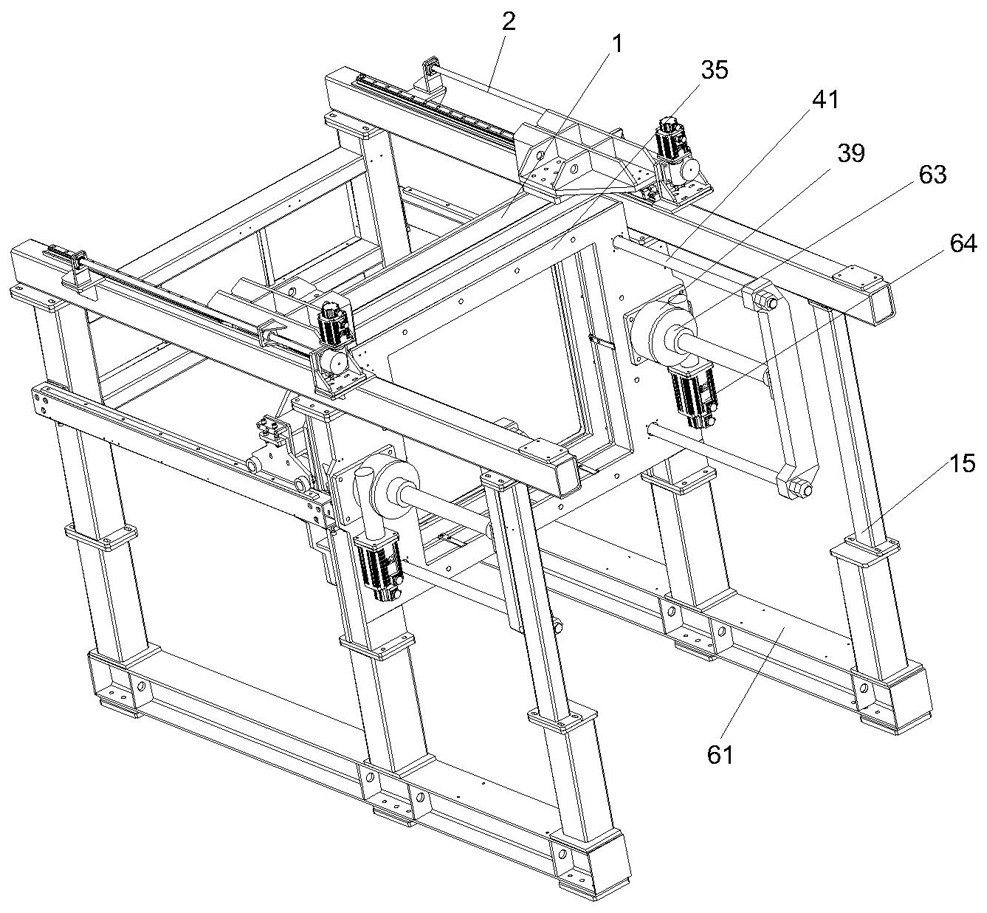

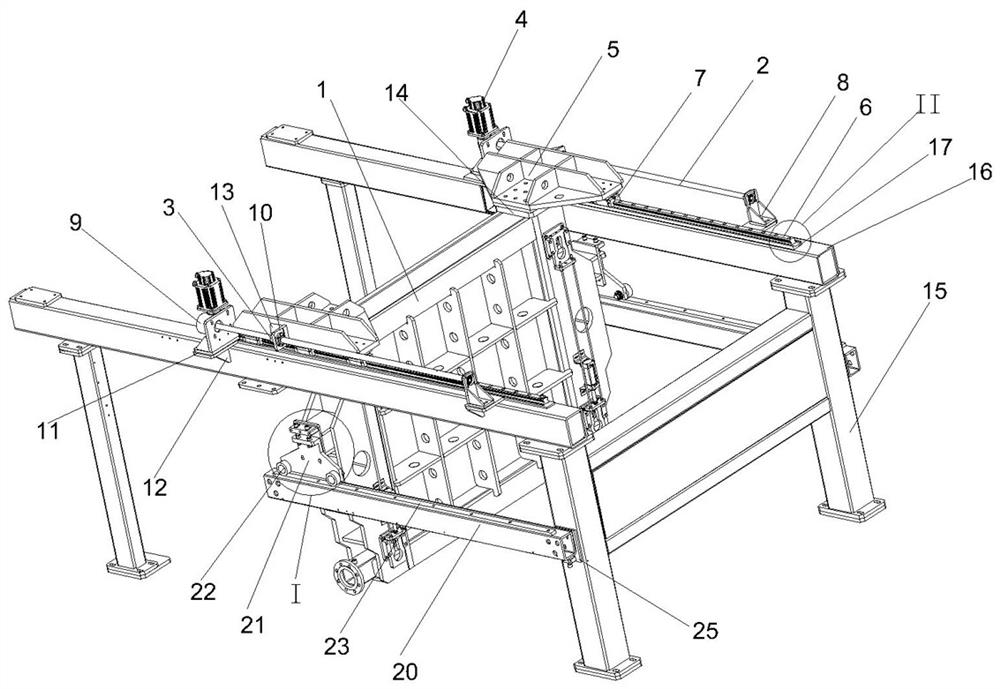

[0040] like figure 1 As shown, a foam molding machine with stable and reliable mold shifting movement and locking includes a bracket, a solid mold 35 fixed on the bracket, a mold shifter 1 that is slidably connected to the bracket, and a device that drives the mold shifter 1 to slide on the bracket. The mold shifting mobile driving mechanism and the mold locking mechanism for locking the mold shifting 1 on the solid mold 2.

[0041] like Figure 3-7 As shown, the driving mechanism for moving the mold includes a pair of first ball screws 2 installed on the top of the bracket and a pair of first servo motors 3 for driving the first ball screws 2. The mold lifting lug 5 is connected to the first ball nut 3 of the first ball screw 2, the top of the bracket is provided with a guide ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com