Exhaust valve assembly, compressor and air conditioner

A technology of exhaust valves and components, applied in the field of compressors, can solve the problems of limited side through hole area, reduced compressor performance, small flow area, etc., and achieve the effects of small blocking area, improved performance, and large flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

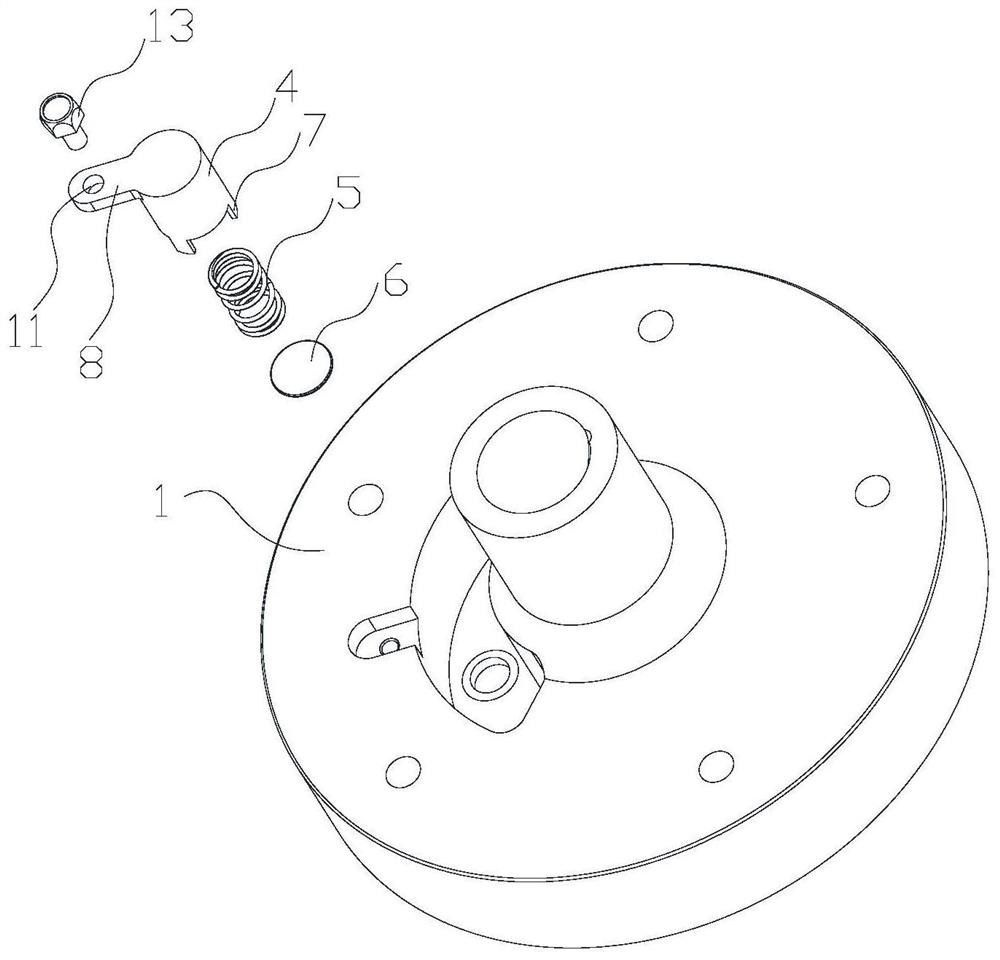

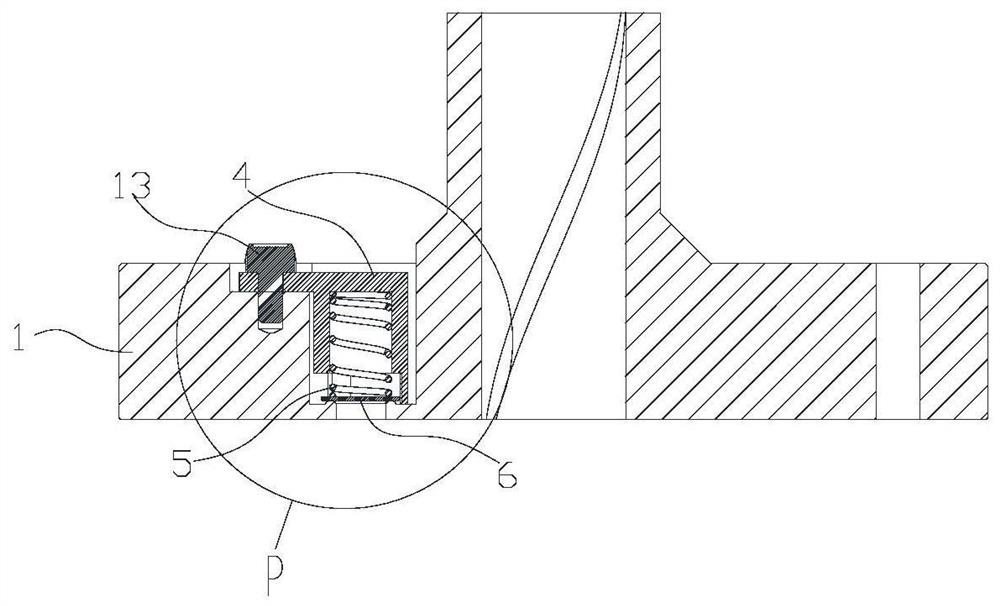

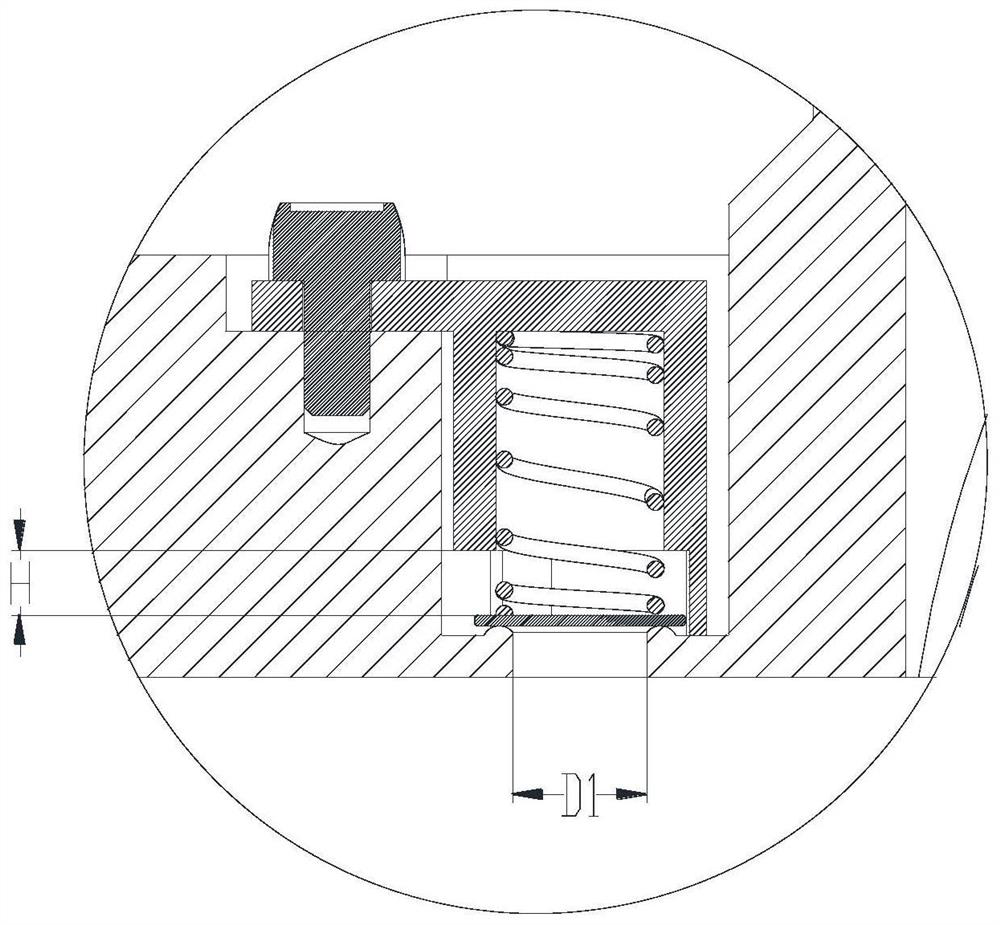

[0036] see in conjunction Figure 1 to Figure 13 As shown, according to the embodiment of the present application, the exhaust valve assembly includes a flange 1 and an exhaust valve group, the flange 1 is provided with a valve seat 2, and the valve seat 2 is provided with an exhaust port 3, and the exhaust valve group includes The mounting seat 4, the elastic member 5 and the valve plate 6, the mounting seat 4 is installed on the flange 1, the valve plate 6 is located between the exhaust port 3 and the elastic member 5, and one end of the elastic member 5 abuts on the valve plate 6, The other end is abutted against the mounting seat 4, and the end of the mounting seat 4 facing the exhaust port 3 is provided with at least two protrusions 7, at least two protrusions 7 are arranged at intervals along the circumference of the mounting seat 4, and the valve The sheet 6 moves in the guide space formed by the lug 7 .

[0037] The exhaust valve assembly is provided with a raised por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com