Intelligent rotor fault experiment device

An experimental device and rotor technology, which is applied in the direction of measuring devices, instruments, and mechanical parts testing, can solve the problems of inconvenient intelligent detection, inconvenient control of equipment rotation, inconvenient adjustment of detection mechanisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

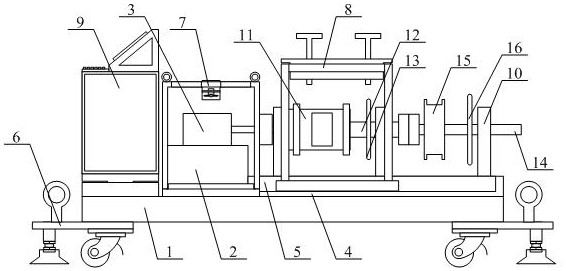

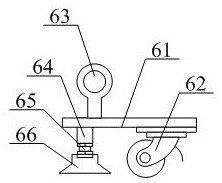

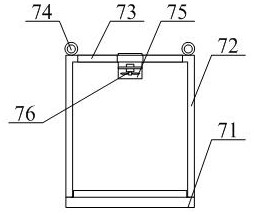

[0023] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, the intelligent rotor failure experiment device includes a base 1, a support 2, a first detection power mechanism 3, a fixed slide rail 4, a chute 5, a hoisting and moving adjustment seat structure 6, and a protective cooling cover structure 7. Slidable detection and adjustment cover structure 8, rotatable operation control cabinet structure 9, support plate 10, second detection power mechanism 11, first rotor 12, first gear plate 13, second rotor 14, pulley 15 and second gear plate 16. The upper left middle position of the base 1 is bolted to the support 2; the upper middle position of the support 2 is bolted to the first detection power mechanism 3; the fixed slide rails 4 are respectively bolted On the right side in front of the upper end of the base 1 and on the right side behind the upper end; the chute 5 is set horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com